CNC Boring

CNC boringis used for the shaft sleeve in the transmission shaft of large equipment, and the tolerance of the bearing position is +0.03mm. After welding the accessories, use CNC horizontal boring and milling equipment to process both sides with a concentricity of 0.05mm.

CNC Boring Capabilities

CNC horizontal milling and boring machine are suitable for machining large and medium-sized parts and box parts rough and fine boring, milling, and other processes. The worktable is equipped with 4x90 ° optical positioning device, which can meet the requirements of large parts turning. The CNC horizontal milling and boring machine are suitable for the hole and plane processing of box parts with many processes, turning of a cylindrical surface, cutting of annular groove in the hole, tapping of male and an English screw thread with a tap, etc. it also has the technological functions of the rectangular coordinate system, polar coordinate system and contour processing of CNC machine tool. Because the CNC horizontal milling and the boring machine have high rigidity and closed-loop detection system, which can meet the requirements of rough and fine machining, the CNC horizontal milling and boring machine is a high-efficiency and precision general-purpose large-scale machining equipment.

CNC Boring Material and Finishes

|

Machinery |

3 |

|

|

Material |

Alloys Steel |

Bronze Alloys |

|

Aluminum Alloy |

Stainless Steel |

|

|

Copper |

Carbon Steel |

|

|

Brass |

POM/PA |

|

|

Features |

Deburring |

Drilling |

|

Tapping |

Milling |

|

|

Threading |

Boring |

|

|

Grinding |

Knurling |

|

|

Maximum Dimensions |

6000mm*2000mm |

|

|

Milling Tolerance |

±0.01mm |

|

|

Inspection Capabilities |

CMM |

Projector |

|

Imaging Measuring Instrument |

Hardness |

|

|

Metallographic Microscope |

Non-destructive Equipment |

|

|

Automatic Thread Inspection Equipment |

||

|

Surface Finished |

Zinc Plated |

Sand Blasted |

|

Nickel Plated |

Blacking |

|

|

TD Coating |

Phosphating |

|

|

Dacromet |

Zinc-Nickel Plating |

|

|

Thread |

UNF |

UNC |

|

NPT |

SAE |

|

|

Metric |

BSPP |

|

|

BSPT |

JIS |

|

|

DIN |

G |

|

|

R |

ZG |

|

|

Certification |

ISO9001-2008 |

ISO/TS16949 |

Advantage of CNC Boring

CNC boring and milling machining has the characteristics of strong rigidity, high machining accuracy and efficiency, good stability, long transverse travel, large bearing capacity and powerful cutting. It is especially suitable for the boring and milling of the large planes and the finishing of large box parts and hole series. In addition to drilling, boring, expanding and reaming, various accessories can also be used for turning, milling and screw pattern processing.

ETCN is a professional cnc company. We provide CNC Machining, Casting, industrial machiningand so on. Want to know more? Please contact us.

Send product request

Other supplier products

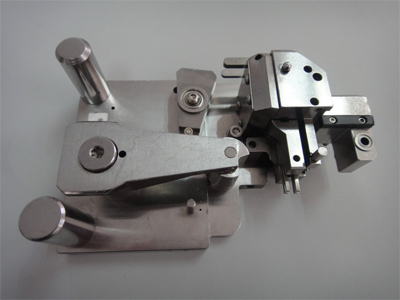

| Automations and Fixtures With CNC Machining | As a professional auto cnc machining ltdcompany, we can supply a high-quality level of CNC automation solutionand parts for the production of all-i... | |

| Stretch Forming | Stretch forming is a technology to stretch the mental into different shaped mental parts. It also will improve the structure of the unloading part ... | |

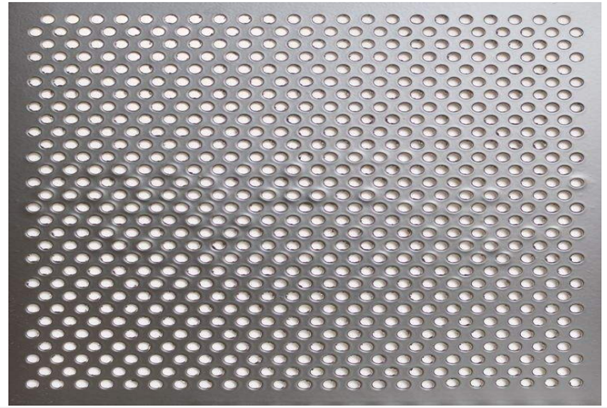

| Cutting | Sheet Cutting Sheet metal cut out is used for air compressor equipment support frame after bending, laser cutting long round hole and welding hexa... | |

| CNC Punching | CNC Punching The products processed by CNC punchingmachines have the characteristics of high stability and high precision, which are suitable for ... | |

| Cold Forging | As a professional part former cold forgingmanufacturer, ETCN provides our clients with precision cold forging die with different types of cold forg... |