Induction Heating Machines In Tube And Pipe Heating

Many industries and factories have laid a large number of pipelines inside their factories because of production requirements. Sometimes customers need to heat or insulate these substances flowing in the pipeline. Induction heating equipment can be used in the existing metal pipe network according to the actual situation. For example, pipeline pre-welding and post-welding heat treatment can be conducted to increase the welding quality. To complete this process, one should heat the pipeline before bending and heat the oil/gas pipes to hold the temperature and the pipelines with chemical material. A high-quality induction pipe heater can heat the partial or whole pipeline network without large-scale modification of the on-site environment. This application widely exists in many industries such as medicine, PVC, petroleum, chemical industry, etc.

The Advantages of Pipes Induction Heater

The traditional heating machines will normally heat the tubes and pipes without partition temperature control. However, when using a professional pipes induction heater, the heating temperature difference of different positions in the outer wall of the pipe or tube is small as the object is heated in a whole ring.

For welds with large pipe diameters, conventional heating machines often require 90,000 watts of power so as to achieve successful tube welding. And during the processing, if there is a heating piece burning, then this area will become the weakest place in the overall weld, which will further embed some hidden dangers to the finished tubes and pipes. However, this problem does not exist for pipes induction heater.

Compared with the conventional far-infrared resistance heating heat treatment, the induction heating treatment conducted by an induction pipe heater is simple, and it can effectively reduce the costs of labor and raw material.

Conventional far-infrared heaters are thermally conducted by heating sheets, and the transmission speed of these machines is slow and the heat loss is severe. Using the induction heating method, our pipes induction heater can better control the temperature difference between the internal and external walls, which effectively guarantees the mechanical properties of the welded joint.

In addition, similar to the metal heating machine, JKZ's pipes induction heater has the advantages of no open flame, high safety, high automation, small install space, easy maintenance, and long use life. Our induction pipe heater has made the pipeline heating method more popular.

Precaution Procedures of Pipes Induction Heater

When using the pipes induction heater, no matter it is a high-frequency induction heater or medium frequency induction heating machine, do not easily remove the grounding wire of the pipe heating equipment.

Regularly check the air outlet and heat dissipation fan of the pipes induction heater so as to prevent the air inlet from being blocked and avoid overheating shutdown.

Clean up the heat sink of the induction pipe heater regularly to ensure that the electromagnetic induction of the pipeline is well ventilated.

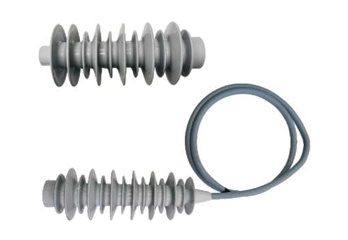

As a professional induction heating machine manufacturer, JKZ sells induction pipe heaters with both water cooling types and air cooling types. With flexible heating cables, the pipes induction heater produced by JKZ can freely wind on various diameters pipelines.

JKZ is a professional induction heating machine manufacturer, we provide induction heating machine china, induction heating power supply and etc. Want to know more? Please contact us.

Send product request

Other supplier products

| MFS-200A 1-8KHZ 200KW 310A Medium Frequency Induction Heating Machine | The converter of the MFS-200A induction heating furnace is IGBT. MFS-200A can work at the power of 200KW, and its frequency ranges from 1KHZ to 10K... | |

| Induction Post Weld Heat Treatment (PWHT) | Local post weld heat treatment (PWHT) is a stress release process by heating the welded zone after the workpiece is welded, which is an indispensab... | |

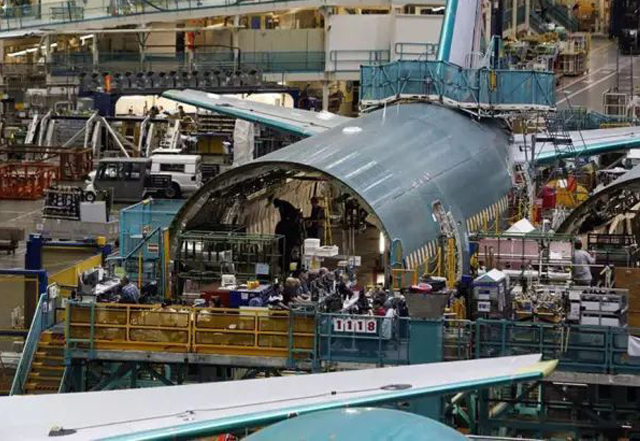

| Induction Heating Machines In Aviation And Aerospace | Aviation and aerospace are manifestations of high standard industrial capabilities. Induction heating is widely used in the aerospace industry, and... | |

| MFS-500A 1-8KHZ 500KW 760A Medium Frequency Induction Heating Machine | The frequency range of the MFS-500A 500KW IGBT type medium frequency generator is from 1KHZ to 10KHZ. Designed based on customers' actual billets s... | |

| Induction Heating Machines | JKZ Induction Heating has been engaged in the manufacturing of induction heating machines for nearly 30 years. At present, there are currently more... |

Same products

| flask | Seller: PakGent Bioscience (Suzhou) Co., Ltd. | Fit tips, DNase/RNase free, sterile, rack pack(78mm) PakGent UFPT-1000R-L Low Retention 1000ul M... | |

| Lesinurad | Seller: Lepu Medical Technology(Beijing)Co.,Ltd | Lesinurad *Product registration and availability vary by country. For more information on prod... | |

| LEN503 Nebulizer | Seller: Lepu Medical Technology(Beijing)Co.,Ltd | Cute pet caring Small atomized particles nebulizer machine for kids Adjustable atomizing cup H... | |

| SINOART Shanghai Co., Ltd. | Seller: SINOART Shanghai Co., Ltd. | SINOART Shanghai Co., Ltd. is a combined industrial & trading company in China, specializing ... | |

| High Voltage Surge Arresters | Seller: Guangdong Yufeng Industries Co.,Ltd | High voltage surge arresters, also called lightning arresters, are electrical devices designed to... |