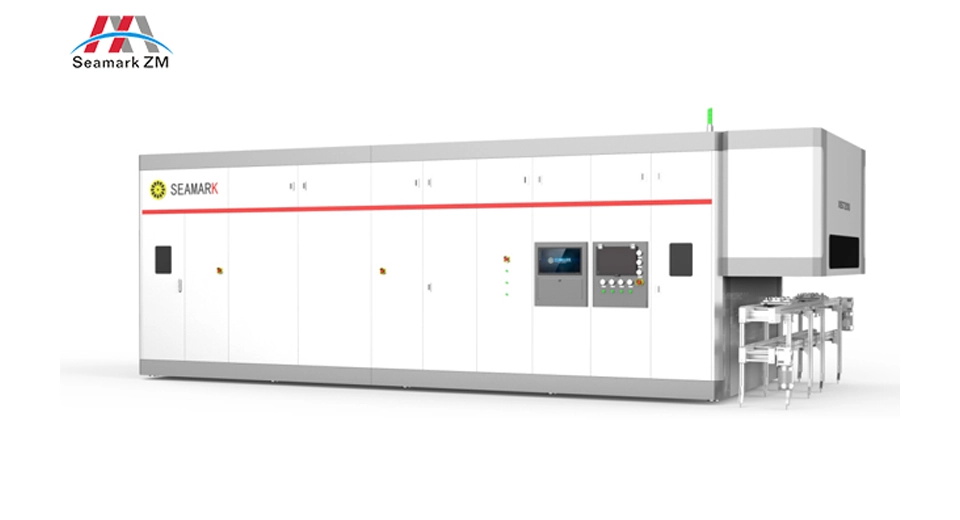

ZM-R720A LED/Micro Component Rework Station

ZM R720Amini bga rework stationis a precision optical intelligent LED rework station suitable for the rework of precision microdevices. This machine adopts imported HD CCD digital imaging, automatic optical zoom system, rework of precision microdevices, carbon fibre infrared BGA heating tube, and automatic feeding. Besides that, Seamarkalso has other types of BGA rework stations for you to choose from.

Functions of R720A Micro/Mini BGA Rework Station

00 Carbon Fiber Infrared Heating Tube

The IR preheating zone uses carbon fiber infrared tube heating and high temperature resistant microcrystalline panel protection, and a multi-functional movable PCB fixing bracket.

01 Precision Tiny Devices and Automatic Feeding

Seamark dedicated to the repair equipment of precision micro devices, automatic feeding device, optional LED feeder feeding fixture.

02 High Definition Display

Using imported high-definition CCD (2m pixels) digital imaging system with automatic optical zoom, automatic control laser red-dot precision alignment, using 15' HD industrial display screen.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable quality, good service. If you want to know the micro BGA rework station and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

Specification Of ZM R720A Micro/Mini BGA Rework Station

|

Power Supply |

AC220V±10% 50/60HZ |

|

Power |

|

|

PCB Size |

412*370mm(Max); 6*6mm(Min) |

|

BGA Chip Size |

60*60mm(Max);0.6*0.6mm(Min) |

|

IR Heater Size |

380*280mm |

|

Temperature Sensor |

1 |

|

Operation Method |

7" HD touch screen |

|

Control System |

Autonomous heating control system V2(software copyright) |

|

Display System |

15" HD industrial display ( 1080P 16:9) |

|

Alignment System |

2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator |

|

Vacuum Adsorption |

Automatic |

|

Alignment Accuracy |

±0.01mm |

|

Temperature Control |

K-type thermocouple closed-loop control with accuracy up to ±1℃ |

|

Feeding Device |

Yes |

|

Positioning |

V-groove with universal fixture |

|

Dimensions |

L810*W635*H870mm |

|

Weight |

We also have bga x ray inspection equipmentfor sale, if you have needs, please contact us.

Send product request

Other supplier products

| X-Ray SMD Component Counting Equipment | Microfocus X-ray inspection is widely used in LED/automobile/aerospace/EMS etc field and become a necessity for modern PCBA inspection. The X-ra... | |

| ZM-R5860 Hot Air BGA Rework Station | Principle And Operation Mode Of Seamark ZM R5860 BGA Machine ZMR5860Hot Air BGA Rework Station is a kind of rework station provided by Zhuomao, ... | |

| Offline Component Counting Equipment | The offline counting machine is a micro-focus X-Ray automatic counting machine. This X-Ray counting machine uses the X-RAY perspective principle... | |

| Inline X-Ray Inspection Machine | In the inspection process of electronic components, the pcb x ray inspection machine can be directly connected to the SMT production line for high-... | |

| Inline Inspection Machine for Stacking Battery | Seamark has 1 model which is an inline winding battery real time x ray machine, it is XB7200. Inline x ray inspectionis widely used in different ki... |