Extra-galvo Scanner

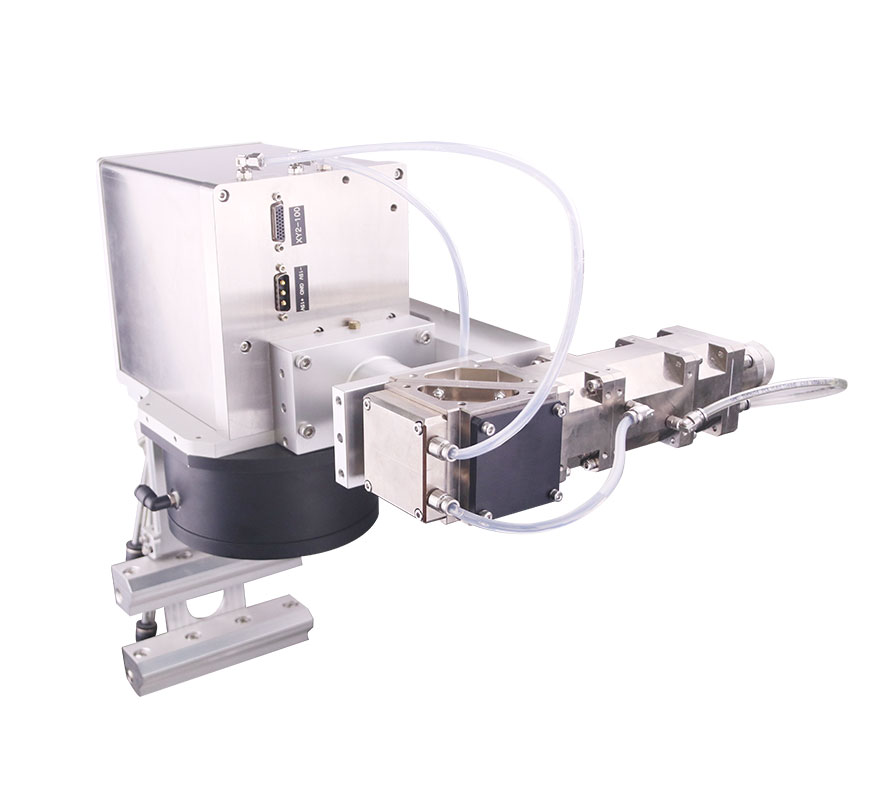

Compared with the photoelectric analog galvanometer, the installation of the grating requires a larger space, so the encoder part at the bottom of the grating digital galvanometer is higher than that of the photoelectric analog galvanometer. The grating digital galvanometer is more stable than the photoelectric analog galvanometer, and has a smaller drift subject to temperature changes. The 23bit resolution digital galvanometer achieves excellent positioning accuracy and repeated positioning accuracy, supports position monitoring and position feedback of the galvanometer, real-time detection of the status, and ensures safe and reliable operation.

Key Features Of Extra-galvano scanner

The single-axis laser galvanometerconsists of a galvanometer part based on moving magnet technology and a high precision sensor as a feedback part.

Through kinematics and dynamics simulation, the mirror with certain inertia is matched for each galvanometer. Moreover, the rotor of the galvanometer has been optimized and has excellent dynamic properties and response characteristics.

Grating galvanometer is a kind of galvanometer with grating encoder as feedback system. It has the characteristics of high resolution, very high repeatability and very low drift, and keeps good repeatability even under the condition of ambient temperature change.

Scanning galvanometermirror is available for common laser wavelengths and energy levels. Besides, all the galvanometer mirrors are optimized to take into account the inertial load, rigidity and flatness of the galvanometer mirrors.

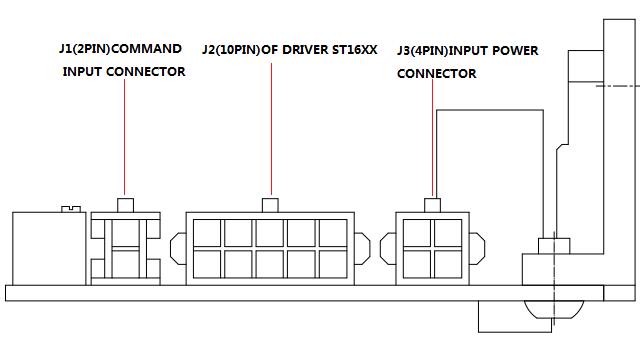

Specifications Of Extra-galvo Scanner

|

Grating Galvanometer |

S |

M |

L |

|

Input Beam Aperture (mm) |

10 |

14 |

20-30 |

|

Moment Of Inertia(g•cm2) |

|||

|

Force Constant(N•mm/A) |

15 |

24 |

|

|

Coil Resistance(Ω) |

|||

|

Coil Inductance(µH) |

155 |

275 |

385 |

|

Maximum Continuous Current(A) |

5 |

||

|

Peak Current(A) |

10 |

10 |

10 |

|

Rise Time(ms) |

|||

|

Weight(g) |

220 |

300 |

400 |

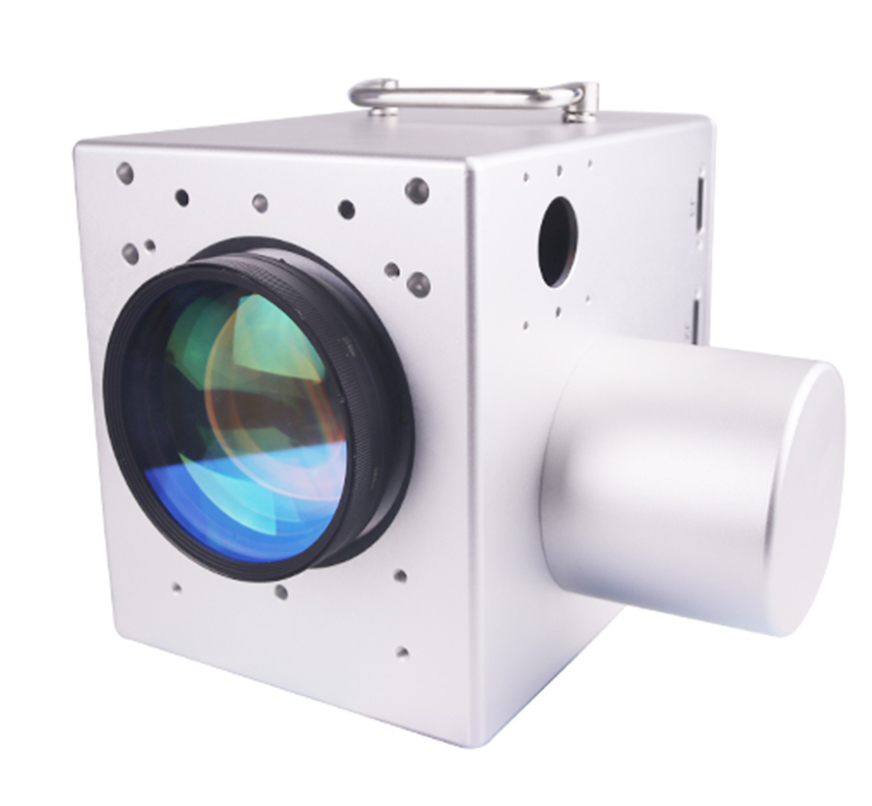

Hans scannerindependent research and development of a series of scanning head systems (7mm, 8.5mm, 10mm, 14mm, 20mm, 30mm, 50mm), with high precision, high speed, high energy, low temperature drift, strong anti-interference ability and other performance, It is widely used in flight marking, precision marking, precision cutting, precision welding, 3D printing, laser drilling, medical cosmetology and ophthalmic imaging and other industries.

Send product request

Other supplier products

| Analog Galvo Driver | Han's galvo scanning systemanalog galvo driver board is designed for the full series of Han's Scanner photoelectric galvanometer motor, using the t... | |

| 3-axis Galvo Scan Head | The large-format 3D laser scanner headis free of the processing range limits of 2D field lenses, and can be flexibly selected 100x100mm-2000x2000mm... | |

| Polygon Scanner | Different from galvanometer control technology, polygon laser scanner has rotary mirror which adopts advanced bearing and spindle design, rotating ... | |

| High Power Galvanometer Welding System | High powergalvo laser weldingsystemis independently developed by Han's Scanner. The system after fully validated, with carefully designed double wi... | |

| 3-axis Galvo Scan Head | The large-format 3D laser scanner headis free of the processing range limits of 2D field lenses, and can be flexibly selected 100x100mm-2000x2000mm... |