12-stage Hydrocyclone System

VD-HC-D series 12 stage starch washing hydrocyclone systemis mainly used to extract refined starch milk, that is, to remove soluble and insoluble proteins and possible tiny fibers contained in starch milk.

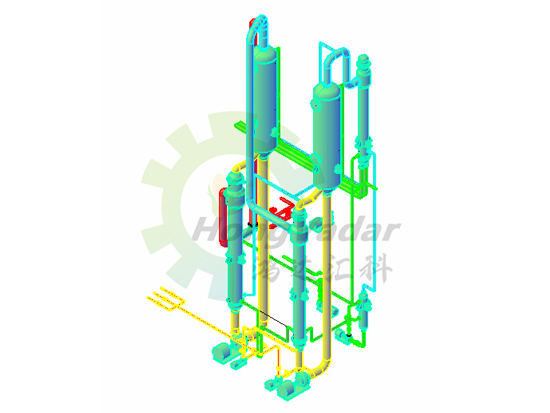

Structure and principle: the cyclone separator consists of housing, orifice plate, cover, cyclone tube, plug tube, etc.

The hydrocyclone working principleis as follows: The starch milk and the washing water go through the hydrocyclone system in a countercurrent way. The hydrocyclone system usually consists of 6 ~ 12 grades. Each stage contains a number of cyclone tubes which are housed in the housing of the cyclone separator and operate in parallel. Each stage of the rotary separator has a feeding interface, bottom flow interface, and overflow interface.

Starch washing cyclone, bottom flow contains concentrated starch milk, overflow contains soluble substances and fine slag. The bottom flow of one stage is sent to the feeding pump of the middle stage along with the overflow of the previous stage. The starch milk first enters the first stage of the washing system, then is washed step by step to reach the required refined starch milk and leaves the system through the bottom flow of the last stage.

The overflow contains dilute starch milk and impurities to be removed. This allows the washing water (which enters the washing system before the final stage) to leave the hydrocyclone system after passing through the stage 1 overflow, removing impurities such as proteins and fine fibrous residues.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy-saving equipment system for the customer. Mentoring is a critical part of the Troubleshooter's role in hydrocyclone troubleshooting.The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Mentoring is a critical part of the Troubleshooter's role in hydrocyclone troubleshooting. Customers can choose international ISO, EU CE, and other standards for equipment design and production according to their needs.

Features of 12 Stage Hydrocyclone System

Good washing and refinery effect.

Stable running and low failure rate.

Easy operation and convenient maintenance.

High production capacity.

12-stage Hydrocyclone System Technical Parameter

|

Model |

Type |

Output capacity(starch ten thousand tons/year) |

Feed pres.MPa |

|

HVD-HC-D200-1 |

Horizontal |

1~1.5 |

|

|

HVD-HC-D250-1 |

Horizontal |

||

|

HVD-HC-D300-1 |

Horizontal/vertical |

||

|

HVD-HC-D350-1 |

Horizontal/vertical |

3 |

|

|

HVD-HC-D410-1 |

Horizontal/vertical |

5 |

|

|

HVD-HC-D450-1 |

Horizontal/vertical |

6 |

|

|

HVD-HC-D350-2 |

Horizontal/vertical |

6 |

|

|

HVD-HC-D410-2 |

Horizontal/vertical |

10 |

|

|

HVD-HC-D450-2 |

Horizontal/vertical |

12 |

|

|

HVD-HC-D500-2 |

Vertical |

15 |

|

|

HVD-HC-D560-2 |

Vertical |

20 |

|

|

HVD-HC-D600-2 |

Vertical |

24 |

|

|

HVD-HC-D750-2 |

Vertical |

30 |

As one of hydrocyclone manufacturers, we will do our best to meet all customers’needs.

If you want to know more about wheat starch processing plant, please contact us.

Send product request

Other supplier products

| Spray Dryer System | HVD-SD-Q a spray dryer works on the principle ofdrying process in which the raw material solution is separated into droplets in an atomizer and the... | |

| Continuous Evaporative Crystallization System | HVD-CC-T series continuous crystallization equipmentsystem is designed and developed by our factory with patent applied. Core Of Evaporative Cry... | |

| 12-stage Hydrocyclone System | HongVader as agricultural processing plants play the roles of corn, sweet corn processing plant, potato processing plant, starch of corn and wheat ... | |

| Full Automatic Intelligent Ion Exchange System | HongVadar Co. abides by the business philosophy of "Take honesty as the foundation and Keep credit to develop", adheres to the practice principles ... | |

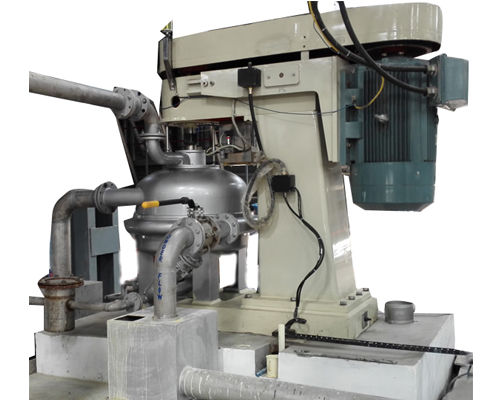

| Disc Separator | In the starch separation process, HVD-SP-P series high speed separatorproduces very high centrifugal force due to high speed rotation, which improv... |

Same products

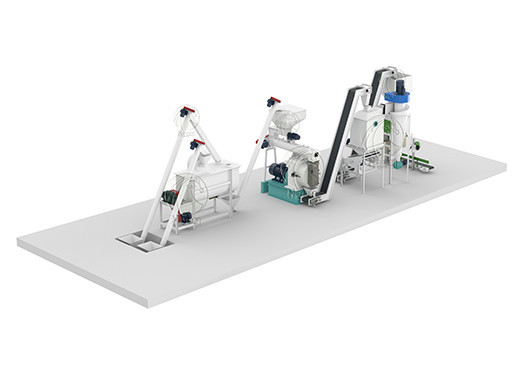

| Poultry Feed Mill Plant | Seller: Henan Herm Machinery Co., Ltd. | Starting a poultry feed processing plant has always been a profitable business in many countries.... | |

| Chicken Feed Mill Plant | Seller: Henan Herm Machinery Co., Ltd. | The process of our automatic chicken feed production line includes grain hammer mills, conveyors,... | |

| 1-2T/H Feed Pellet Line | Seller: Henan Herm Machinery Co., Ltd. | This 1-2 t/h feed pellet line is suitable for processing various animal feed pellets, such as pou... | |

| 3-4T/H Feed Mill Plant | Seller: Henan Herm Machinery Co., Ltd. | Our 3-4 tons/hour feed pellet production line is suitable for processing various animal feeds, su... | |

| 3-4T/H Feed Pellet Line | Seller: Henan Herm Machinery Co., Ltd. | Our 3-4 t/h feed pellet line is suitable for processing various animal feeds, such as chicken fee... |