Bio-Polishing Enzymes

Textile enzyme is a highly effective neutral cellulase preparation produced by the fermentation of trichoderma. Biopolishing enzymes textile industryis suitable for washing of towel fabric, can remove the surface hairiness, pellets, the treated towel fabric is softer, fluffy and drape well. This product has excellent anti-dyeing performance and no pollution to equipment, environment and fabric.

Product info

BioPolishing EnzymesUse Method

Temperature: 45-55 ℃, the best temperature 50 ℃;

PH: between 5.5 and 7.5, with an optimum PH of 6.5;

Washing time: 15-60 minutes, depending on the desired effect. The longer the time, the more significant the effect.

Dosage: 0.4-1% (o, w, f), the larger the dosage, the more significant the effect;

Bath ratio: 1:8-1:5;

Direct use without acid regulation;

Inactivate the enzyme: please immediately after washing to prevent excessive treatment of the fabric;

The enzyme can be killed in any of the following ways;

BioPolishing EnzymeAttributes

Appearance: light color solid powder;

PH: 5.5-7.5;

Smell: no special smell;

Stored in a cool and dry place, with less than 5% enzyme activity loss every 3 months;

Corrosion: this product has no corrosion on the equipment;

Injury: this product is not harmful to the skin. If it gets infected by accident, please rinse it with water immediately.

Packing: standard packing: 20Kg/drum.

This product is prepared by concentrated spray drying without compounding. Appearance of light color powder. Under the guidance of the company, customers can produce neutral powder enzyme powder of different grades and application effect with 4-50% blending amount in the following ways. The product can be used at room temperature (cold water environment) and medium temperature (40-55℃) to save intermediate costs and increase operating profits.

All the finished products include the following ingredients:

Neutral textile enzymes 4%, 8%, 10% or higher

Sodium dihydrogen phosphate 55%

Sodium hydrogen phosphate two 5%

Color killer 10-30%

Sodium sulfate 0-6%

In the combination, the user can choose the flower agent and refueling agent which have no harm to the enzyme activity to mix with the original enzyme. The paint remover requires a surfactant with a certain penetration and washing capacity. In order to ensure the stability of product quality, it is suggested that users choose the special starting and refueling agent.

Storage of packaging

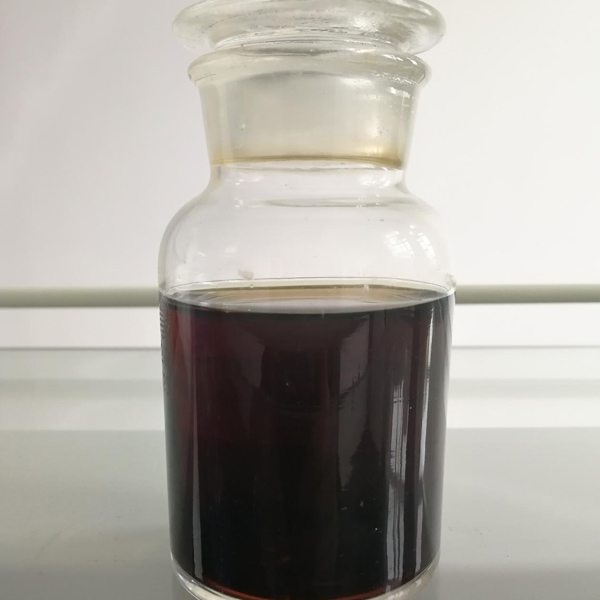

This product is the concentrated fermentative liquid without compound, and its appearance is dark clear liquid. Under the guidance of the company, the customer can combine the acidic liquid enzyme preparation of different grades and use effects in the following ways with the proportion of 10% to 80%, so as to save intermediate cost and increase operating profit. The PH value of the mixture can be adjusted by glacial acetic acid, oxalic acid or dilute sulfuric acid and dilute hydrochloric acid.

Bio-Polishing Enzymes Ingredients

Acid textile progenase: 10%, 20%, 30% to 80%

The mixed liquid 0-87%

The lighter color agent 3-20%

Table sugar 20 sodium benzoate 4 sodium benzoate 0.2 potassium sorbate 0.2

Sodium thiosulfate 0.15 water 75.45

Total 100

The above materials shall conform to the related standards of food additives.

Water is heated to 60 ℃ or so,

* Note the order of adding materials, adjust pH to 4.6~4.9 with acetic acid or citric acid. Storage of spare.

Our special paint additive is a kind of surfactant mixed with different HLB values. Users can also choose other refueling agents that are not harmful to enzyme activity. The blending amount of refueling agent can be determined by the requirements of color removal and color retention.

The dosage is 3%-6%. General rules for the preparation of the product, the more the amount of the original enzyme, the more refueling agent required.

The dosage is 10%-20%. The general rule is that the more the original enzyme is added, the more the refueling agent is required. Our special toner contains insoluble substance, please add when the mixture is high temperature.

Send product request

Other supplier products

| Mesothermal Alpha Glucoamylase | Mesothermal Alpha Glucoamylase is extracted by Bacillus any breach No.BF7658 after liquid culture and fermentation, which can efficiently catalyze ... | |

| Acid Lipase | Acid lipase enzyme powder is a kind of lipase extracted from aspergillus Niger strain. Typical application fields include feed, food, medicine, che... | |

| Pullulanase | Pullulanaseis produced from Bacillus licheniformis by deep fermentation. It can be widely used in beer, starch sugar, monosodium glutamate, alcohol... | |

| Acid Cellulase Enzyme (Powder) | Cellulase is refined by liquid-deep fermentation and after-treatment. Cellulase is a group of enzymes that degrade cellulose to produce glucose. It... | |

| Alkaline Protease | Alkaline proteasewas extracted by liquid culture of Bacillus licheniformis NO.2709. This product is an enzyme preparation catalyzing protein hydrol... |

Same products

| Pectinase | Seller: Jinan Bestzyme Bio-Engineering Co., Ltd | Pectinase for Sale This product is a mixture of pectinose and pectinase which are obtained by As... | |

| Neutral Protease | Seller: Jinan Bestzyme Bio-Engineering Co., Ltd | Neutral Protease Neutral protease catalyzes peptide bond and hydrolyzes protein into peptone, hy... | |

| Applications | Seller: Jinan Bestzyme Bio-Engineering Co., Ltd | Beta Glucanase Enzyme Uses Bestzyme enzymes are widely used in feed and industrial fields. For i... | |

| Beta Mannanase | Seller: Jinan Bestzyme Bio-Engineering Co., Ltd | β mannanase is a feed hemicellulase fermented by the improved strains using a liquid ferment... | |

| Study on the Application of Protease in Food Industry | Seller: Jinan Bestzyme Bio-Engineering Co., Ltd | The role of protease in meat products The content of muscle fiber protein and collagen in meat i... |