Rice Hulls Pellet Mill/Agriculture Waste Pellet Mill/Pellet mill

How to Improve the Additional Value of Rice Husk?

In the rice production, in addition to rice, there are many other renewable resources left such as rice husk, rice bran and straw. Rice husk are shells separated from rice through the rice hulling process. Southeast Asian countries are major production areas in the world for rice. How can we use these resources rationally? And how can we increase the additional value of rice husks? The answer is to adopt therice hulls pellet millor the rice husk pellet machine.

Working Principle of the Rice Husk Pellet Machine

Crushed and ground materials vertically fall on the frame plate surface from the rice hulls pellet mill’s feeding inlet and are continuously and uniformly distributed on the mold cavity surface as the frame plate rotates. After being ground by the pinch roller, powder materials go through the mold holes. Then by suffering high pressure and high temperature treatment, these powder materials have gradually changed into extended cylindrical solids. These cylindrical solids will constantly lengthen until being cut into a certain sized particles by uniformly distributed cutters around the mold. Particle materials scattered around the rice hulls pellet mill mold are concentrated to the discharge port by the briar dressing gear, and then automatically fall under the action of gravity.

What materials can Fote rice hulls pellet mill process?

Raw materials: rice husk, rice bran, straw, seeds shells, peanut shells, sawdust, grass, husks, twigs, bark, stump, pine sawdust and crop stalks.

How can Fote rice hulls pellet mill create value continuously?

If you want yourrice husk pellet machineworks stably, it is necessary to carry out a series of maintenance work for the ring die of the equipment.

1. Drill the ring die: Holes stuffed with iron materials should be drilled.

2. Grind the ring die: Uneven face of the ring die should be rubbed down.

3. Ream the die holes: Those shrinking holes should be repaired with the proper cone angle of 60 °.

4. When replacing the ring die, die holes need to be first filled with oily materials, so as to ensure the ring die to work in the best condition inn later production.

More preparation may increase working efficiency. Timely maintenance can ensure the stable performance of the pellet mill and at the same time helps to bring us more profit.

Send product request

Other supplier products

| Corn Straw Pellet Mill/Straw Pellet Mill/ Pellet Mill | Advantages ofFote corn straw pellet mill 1.Good quality and proper price. Our maize straw pellet mill not only covers the domestic market, but also... | |

| Crushing Machine/Impact Crusher/Fote Imapct Crusher | As indispensable machines for mining industry, crushing machines like cone crusher andimpact crushing machineshould be selected appropriately. Fote... | |

| Biomass Briquette Machine/High Quality of Biomass Briquette Machine | What is the biomass fuel? The biomass fuel is created by a special biomass briquetting machine which can press all kinds of wood wastes into new gr... | |

| Jaw Crusher/Small Jaw Crusher/ Mobile Jaw Crusher | Remarkable features of jaw crusher machine 1. Strong crushing capacity We use the finite element analysis to increase the radical crushing strength... | |

| Hydraulic Briquette Machine/Briquette Machine/Price of Briquette Machine | Finished product of hydraulic briquette machine has two kinds: metallurgical iron briquette and metallurgical iron powder briquette. For metallurgi... |

Same products

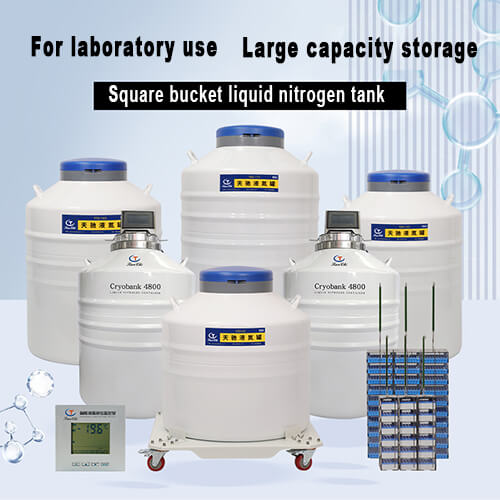

| Togo cell freezing container KGSQ Liquid Nitrogen Field Tank | Seller: Henan Tianzhidao Biological Technology Co., Ltd | The use of liquid nitrogen tanks covers scientific research, animal husbandry, gourmet food, beau... | |

| Burundi liquid nitrogen container for cell storage KGSQ cryo dewar | Seller: Henan Tianzhidao Biological Technology Co., Ltd. | The use of liquid nitrogen tanks covers scientific research, animal husbandry, gourmet food, beau... | |

| Ukraine large diameter liquid nitrogen container KGSQ nitrogen tanks | Seller: Henan Tianzhidao Biological Technology Co., Ltd | In biological sample centers or scientific research institutions, there are a large number of cel... | |

| Cambodia gas-phase liquid nitrogen tanks KGSQ liquid nitrogen container | Seller: Henan Tianzhidao Biological Technology Co., Ltd. | In biological sample centers or scientific research institutions, there are a large number of cel... | |

| Electroplated Tools | Seller: Henan E-Grind Abrasives Co., Ltd. | Henan E-Grind Abrasives Co., Ltd. produces electroplated tools by plating diamond or CBN grains w... |