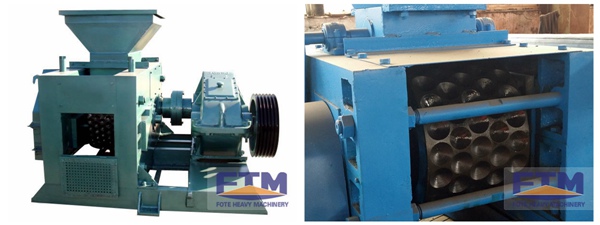

Peanut Hull Pellet Mill/Coconut Shell Pellet Mill/Fote Pellet Mill

Is the peanut hull worthless?

Peanut shells are byproducts of peanut. The effective utilization rate of peanut shells is very low, because they are burnt directly or are used to feed animals generally. People of most areas in the world have realized to turn the peanut shells into treasures is necessary. Our company’sPeanut Hull Pellet Millcan process them into particles used as a new kind of biomass energy. The application of peanut shell pellet machine offers a new way of realizing energy saving and environmental protection, and making profits for customers.

How does Fote peanut hull pellet mill turn waste into treasure?

Fote peanut shell pellet machineis an amazing high efficiency equipment which can pelletize solid biomass wastes such as peanut shells, corn stalks, wheat straw, corn stover, corn cob, cotton stalks, soybean stem, weeds, twigs, leaves, sawdust and bark into particles with professional production technology. The finished pellet fuel is a new kind of bio-energy which can replace wood, coal, crude oil, liquefied natural gas. It is widely used in fields of heating, cooking, industrial boilers, chemical plants, biomass power plants etc.

Prospect Analysis of the Peanut Hull Pellet Mill

Most countries in the world, especially developed ones, are committed to development and application of biomass energy, aiming to protect national mineral resources and guarantee the energy security. Pellets produced by Fote peanut hull pellet mill are clean fuel that can replace coal, petroleum and gas which successfully responses to the international call for energy saving and environment protection. In addition, raw materials for the pellet machine are abundant and cost little. Investing in the project will produce incalculable market value.

Tips:

1. The length of the finished particles is determined by the height of the cutter on the discharging port. 2. The particles’ temperature is relatively high, so we need to cool the products down before they are packaged. The counter flow type cooler made by our company will be your ideal choice.

3. Ring die of the pellet machine should be cleaned regularly to ensure that the equipment runs smoothly.

Send product request

Other supplier products

| Quicklime Briquette Machine/the Quality of Briquette Machine | The quick lime dry powder briquetting machine with other names of lime briquetting machine and lime briquette machine can complete the pressing wor... | |

| Coal Briquetting Plant/Briquetting Plants/Briquetting Plant Manufacture | Fote briquetting plants or briquette plants have a wide practical application, and it can produce briquetting and agglomeration from various materi... | |

| FTM VSI Crusher/Sand Maker/Sand Crusher | Along with the improvement of scientific technology, artificial aggregates are more and more used in water conservancy and hydropower industries. T... | |

| 4-6T/H Tree Bark Pellet Production Line/Pellet Production Line | Application: low adhesion rate and difficulty forming materials: bark, branches, tree trunk, rice husk, sunflower shells, peanut shells, wood chips... | |

| Coal Briquette Plant/The Introduction of Briquetting Plant/Briquetting Plant | For the, it is necessary to make daily maintenance and checks. According to the instructional books, you should often check the following details l... |

Same products

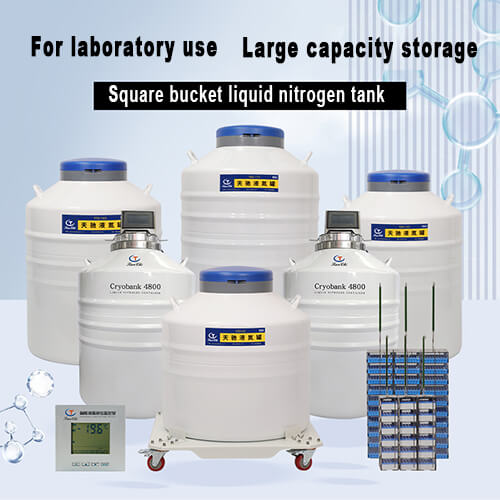

| Togo cell freezing container KGSQ Liquid Nitrogen Field Tank | Seller: Henan Tianzhidao Biological Technology Co., Ltd | The use of liquid nitrogen tanks covers scientific research, animal husbandry, gourmet food, beau... | |

| Burundi liquid nitrogen container for cell storage KGSQ cryo dewar | Seller: Henan Tianzhidao Biological Technology Co., Ltd. | The use of liquid nitrogen tanks covers scientific research, animal husbandry, gourmet food, beau... | |

| Ukraine large diameter liquid nitrogen container KGSQ nitrogen tanks | Seller: Henan Tianzhidao Biological Technology Co., Ltd | In biological sample centers or scientific research institutions, there are a large number of cel... | |

| Cambodia gas-phase liquid nitrogen tanks KGSQ liquid nitrogen container | Seller: Henan Tianzhidao Biological Technology Co., Ltd. | In biological sample centers or scientific research institutions, there are a large number of cel... | |

| Electroplated Tools | Seller: Henan E-Grind Abrasives Co., Ltd. | Henan E-Grind Abrasives Co., Ltd. produces electroplated tools by plating diamond or CBN grains w... |