Straw Pellet Production Line/The Details of Straw Pellet Production Line

Straw pellets contain tremendous energy.

The straw pellets or grains contain a lot of nutritional ingredients, so they can be used as fodder which will provide livestock with necessary nutrition and promote the development of the animal husbandry as well as fuel which will make great contribution to the environment protection cause because of its lower CO2 and SO2 emission amount in comparison with coal. Then, how can we transform straws or crop stalks into straw pellets? To adopt the straw pellet production line will be the best answer.

Fote straw pellet production line makes full use of straw pellet energy.

The straw pellet millis a special machine to process straws. Through years’ research and development, Fote Machinery has made a new type of straw pellet production line which can pelletize all agricultural wastes including crop stalks, peanut husk, saw dust, and tree branch and bark into biomass fuel pellets. As for the pelletizing performance, Fote straw pellet production line adopts the vertical ring die structure with the vertical feeding principle in order to prevent the raw material blocking phenomenon, adopts the static pelletizing mold with rotating press rolls in order to increase the productivity and adopts the double ring dies design which can make two types of pellets with different specifications in order to reduce the production cost. The finished products feature smooth surface, compact structure, high combustion ratio and rare nutrition running off, which realizes the fullest use of the straws.

.jpg)

Be a good master of the straw pellet mill and production line

Fote straw pellet milland production line can only make great contribution for long in good condition which will be realized with proper maintenance and good knowledge of its properties.

1.Maintenance: before starting the pellet machine, add proper amount of clean lubricant oil; notice that the temperature of the main shaft antifriction bearing should not exceed 65℃; try to avoid the equipment rustiness.

2.Malfunction and solution: the varying pellet length can be solved by adjusting the slicer distance or material separation and deflection scraping position; when pellets are smooth but too hard because of the excessive compression rate of the ring die, they can be improved by decreasing the compression rate; when vertical or radial cracks are formed in the pellets or when the pulverization rate gets too high, users should elevate the hardening and tempering temperature and increase the vapor amount; sometimes straw pellets will be broken or torn down because the slicer is too blunt and installed too far away.

For more information, please send us s:

Send product request

Other supplier products

| FTM Sand Crusher/ Gravel Material Crusher/Sand Maker | To process gravel materials, we can use VSI crusher.VSI crusher, also called as sand maker, is a kind of international-level, high-efficient and en... | |

| Rotary Drum Dryer/New Type Dryer Machine/Hongxing Rotary Drum Dryer | Application Range:construction materials, metallurgy, chemical engineering, cement production Applicable Materials:slag, limestone, limestone, coal... | |

| Cotton Stalks Pellet Mill/Cotton Stalks Pellet Machine/Fote Pellet Mill | Do you know the value in cotton stalks? Cotton is mainly harvested in monsoon season or fall. And it is planted in tropical and subtropical region... | |

| Peanut Hull Pellet Mill/Wood Pellet Mill/Fote Pellet Mill | Introduction to Fote Peanut Hull Pellet Mill Aiming to recycle the energy, save the cost and reuse the waste, Fote Company has invented the biomass... | |

| FTM Cone Crushers/ Supplier of Cone Crushers/ Cone Crusher | Non-metallic minerals are the materials that we use at earlier periods. Development of modern technology and industry strongly impels the revolutio... |

Same products

| Felt Polishing Wheel Drum | Seller: Keying Abrasives | The steel wool polishing wheelDrum is particularly suitable for polishing larger surfaces. The st... | |

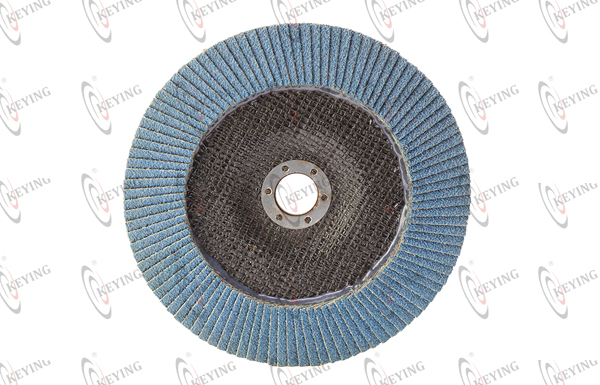

| 7 Inch (180mm) Flap Disc | Seller: Keying Abrasives | KEYING manufactures Self-adhesive Disc, our production is about reprocessing jumbo rolls of SCM, ... | |

| LEN503 Nebulizer | Seller: Lepu Medical Technology(Beijing)Co.,Ltd | Cute pet caring Small atomized particles nebulizer machine for kids Adjustable atomizing cup H... | |

| SINOART Shanghai Co., Ltd. | Seller: SINOART Shanghai Co., Ltd. | SINOART Shanghai Co., Ltd. is a combined industrial & trading company in China, specializing ... | |

| FPQ2W-10/3T20 10kV Pin Insulators | Seller: Guangdong Yufeng Industries Co.,Ltd | The crimping process of polymer pin type insulatorsshould pay attention to the crimping force, co... |