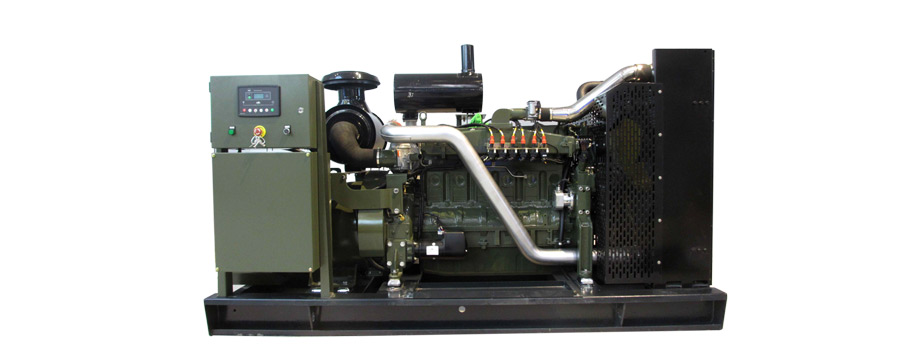

Biomass Genertor power generation

Biomassgasificationpowergenerationistoconvertthebiomassmaterialslikericehusks,woodchips,straws,cornstalks,palmshells,andetcinthegasifiertothegasfuel,afterpurificationthendirectlyintothegas-enginetogenerateelectricity.

Follows are our products catalog:

More information, pls visit

Biomassgasificationpowergenerationcanberealizedbythreeways:

- Biomassaftergasifyingbecomesgasfuelwhichisdirectlyintothegasfiredboilertoproducesteam,andthendrivethesteamturbineforthepowergeneration.

Accordingtothepowergenerationandinvestmentscale,theabovecorrespondinglymatchalongwiththelarge-scale,medium-scaleandsmallscalepowergeneration.

Nowadays,themostcommerciallysuccessfulbiomassgasificationpowergenerationtechnologyhasbeenwidelypromotedandutilizedforitsproductfeatureasfollowing:smallinstalledcapacity,flexiblelayout,lessinvestment,compactstructure,reliabletechnology,lowoperatingcosts,significanteconomicbenefits,simpleoperationandmaintenance,andinferiordemandonthegasquality.

Biomassgasificationpowergenerationsystemconsistsofgasifier,gasfuelpurificationsystemandgasengine.Itconvertsvariouswastesintohighqualityelectricitytosolvethewastepollutionproblemsandmakerationaluseofresourcesandenergy.

Gasifier,alsocalledgasificationfurnaceorgasproducer,isthedevicetotransformthebiomassmaterialfromsolidstatetogasfuel.Biomassmaterialsdotheincompletecombustioninthegasifierbycontrollingtheairsupplytorealizetheconversionoflowvaluebiomassenergyfromsolidstatetogaseity.ItgeneratesthegasfuelcontainingthecombustiblecomponentslikeH2,CO,CH4,CnHmandetc,thentoaccomplishthebiomassgasificationprocess.

Send product request

Other supplier products

| complete rice milling line | Thewholelineconsistsofpaddypre-cleaningmachine,paddyde-stoningmachine,paddyhullingmachine,paddyseparatingmachine,ricemillingmachine,ricepolishingma... | |

| High speed transplanter | Highspeedtransplanter Model:SLRT-6DK Highspeedtransplanter,calledalsoasridingtransplanter,isthemachinewithhigh-technology.Comparingwithwalkingtra... | |

| Biomass Genertor power generation | Biomassgasificationpowergenerationistoconvertthebiomassmaterialslikericehusks,woodchips,straws,cornstalks,palmshells,andetcinthegasifiertothegasfue... | |

| Mini-combine harvester | Mini-combineharvesterishead-feedmicro-ricecombinewithmostadvancedtechnologynowadays.Itfeaturesinricestrawreclamation;easyoperation,smallmeasurement... | |

| Rice packaging machine | Ricepackagingprocessistoweighthefinishedriceintherequiredweight,putthemintoplasticbagorinwovenbag,thensealthebagtomakeapackagefortheeasytransportat... |

Same products

| Ukraine large diameter liquid nitrogen container KGSQ nitrogen tanks | Seller: Henan Tianzhidao Biological Technology Co., Ltd | In biological sample centers or scientific research institutions, there are a large number of cel... | |

| Cambodia gas-phase liquid nitrogen tanks KGSQ liquid nitrogen container | Seller: Henan Tianzhidao Biological Technology Co., Ltd. | In biological sample centers or scientific research institutions, there are a large number of cel... | |

| Electroplated Tools | Seller: Henan E-Grind Abrasives Co., Ltd. | Henan E-Grind Abrasives Co., Ltd. produces electroplated tools by plating diamond or CBN grains w... | |

| Electroplated Diamond Tools | Seller: Henan E-Grind Abrasives Co., Ltd. | Electroplated diamond drill bitscan be made in various shapes, so it will be an excellent option ... | |

| Electroplated CBN Tools | Seller: Henan E-Grind Abrasives Co., Ltd. | Electroplated cbn wheelcan be made in various shapes, so it will be an excellent option when the ... |