Rice Hulls Pellet Mill/Corn Straw Pellet Mill/ Fote Pellet mill

How to Improve the Additional Value of Rice Husk?

In the rice production, in addition to rice, there are many other renewable resources left such as rice husk, rice bran and straw. Rice husk are shells separated from rice through the rice hulling process. Southeast Asian countries are major production areas in the world for rice. How can we use these resources rationally? And how can we increase the additional value of rice husks? The answer is to adopt theor the rice husk pellet machine.

.jpg)

Working Principle of the Rice Husk Pellet Machine

Crushed and ground materials vertically fall on the frame plate surface from the rice hulls pellet mill’s feeding inlet and are continuously and uniformly distributed on the mold cavity surface as the frame plate rotates. After being ground by the pinch roller, powder materials go through the mold holes. Then by suffering high pressure and high temperature treatment, these powder materials have gradually changed into extended cylindrical solids. These cylindrical solids will constantly lengthen until being cut into a certain sized particles by uniformly distributed cutters around the mold. Particle materials scattered around themold are concentrated to the discharge port by the briar dressing gear, and then automatically fall under the action of gravity.

What materials can Fote rice hulls pellet mill process?

Raw materials: rice husk, rice bran, straw, seeds shells, peanut shells, sawdust, grass, husks, twigs, bark, stump, pine sawdust and crop stalks.

How can Fote rice hulls pellet mill create value continuously?

If you want your rice husk pellet machine works stably, it is necessary to carry out a series of maintenance work for the ring die of the equipment.

1. Drill the ring die: Holes stuffed with iron materials should be drilled.

2. Grind the ring die: Uneven face of the ring die should be rubbed down.

3. Ream the die holes: Those shrinking holes should be repaired with the proper cone angle of 60 °.

4. When replacing the ring die, die holes need to be first filled with oily materials, so as to ensure the ring die to work in the best condition inn later production.

Email:

Send product request

Other supplier products

All supplier products

Sawdust Dryer/Fote Pellet Dryer/ China Sawdust Dryer

Introduction

, refers to sawdust drying machine or sawdust rotary dryer, means to continuously feed wet sawdust powder into dry tubes with screw co...

Metal Crusher /Fote Scrap Metal Crusher/Scrap Metal Crusher Machine

The Advantages and Benefits of Metal Crusher:

has low energy consumption, high output, flexible operation, high utilization rate and maintenance co...

Sunflower Seeds Hull Pellet Mill/ Seeds Shell Pellet Machine/Pellet Mill

How does the sunflower seeds hull pellet mill come about?

Sunflower seed hulls are by-products in the sunflower seeds or melon seeds deep proces...

Corn Straw Pellet Mill/China Corn Straw Pellet Mill/Pellet Mill

How can Fote corn straw pellet mill create value?

Common agricultural wastes such as corn stalks, cotton stalks, soybean straw, rice straw, wheat s...

Dry Powder Briquetting Machine/Fote Briquette Machine/Briquetting Plant

or the dry powder ball pressing machine (also used as the sludge, sinter, and quick lime briquette machine) is an excellent device able to bear hig...

Same products

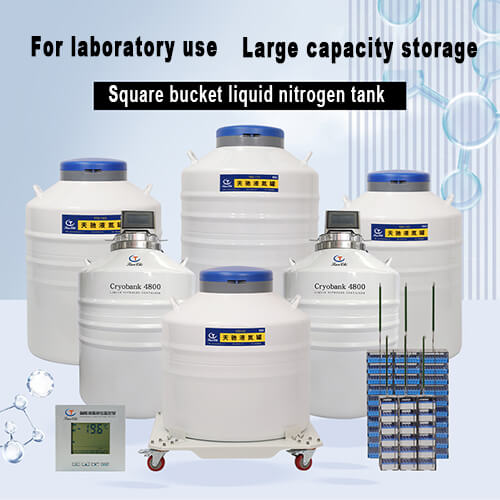

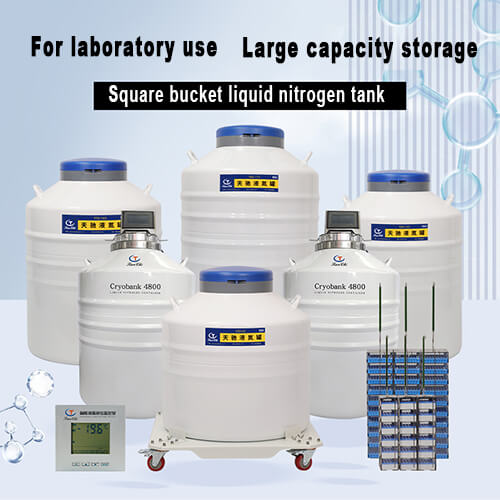

Bosnia and Herzegovina liquid nitrogen tank for laboratory KGSQ

Seller: Henan Tianzhidao Biological Technology Co., Ltd

In laboratories, most commonly used liquid nitrogen tanks have large capacity, large diameter, an...

Tanzania sperm cell storage KGSQ ln2 vessel

Seller: Henan Tianzhidao Biological Technology Co., Ltd.

In laboratories, most commonly used liquid nitrogen tanks have large capacity, large diameter, an...

Ebike Battery

Seller: Shenzhen Worldpower Energy Storage Technology Co.,Ltd

Custom Ebike Lithium Battery Manufacturer

Elevate your electric biking experience with Worldpowe...

Battery Energy Storage Systems

Seller: Shenzhen Worldpower Energy Storage Technology Co.,Ltd

Battery Energy Storage Systems (BESS) are cutting-edge technologies that store electrical energy ...

Felt Polishing Wheel Drum

Seller: Keying Abrasives

The steel wool polishing wheelDrum is particularly suitable for polishing larger surfaces. The st...