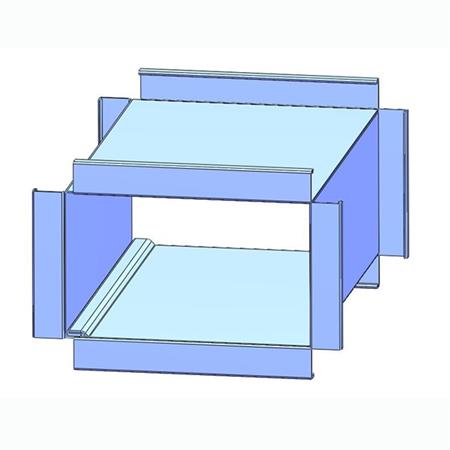

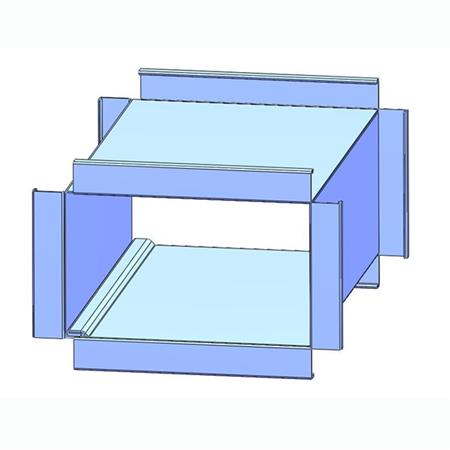

LOCK FORMER

Thelockformer machine, also known as the seam forming machine, the edge side processing machine, the air duct lock forming machine, is a multifunction machine, mainly used for the duct lock processing of plate connection and round duct closed connection. It is very common in industrial development. For the production of many kind of materials, such as pipe material, the appearance of lock forming machine is undoubted a good news, which can meet the various shapes of lock manufactured of duct. The thickness of the processed sheet is 0.4-1.2 mm. All the gears, shafts and rolls of the machine are made of high-quality steel.

After strict heat treatment process, the machine is durable and of stable quality. It is easy to install, and also has beautiful appearance and reasonable mechanical principle with flexible in movement, convenient in operation and so on. It can meet different requirements of users. The lock forming machine is suitable for the production of air ducts for air-conditioning ventilation, fire-fighting and smoke-free, dust-free purification, etc. According to requirements, it can be made into various round and rectangular thin-plate ducts, which are various sheet metal processing, duct production, etc. Indispensable mechanized equipment.

The feature of usage of lock forming machine

- Before use, the debugging of the feeding guide rail should be strictly in accordance with the debugging requirements of the equipment, and the feeding guide rail should be adjusted to the specified position size and then be fixed. Before use, the debugging of the feeding guide rail should be strictly in accordance with the debugging requirements of the equipment, and the feeding guide rail should be adjusted to the specified position size and then be fixed. If the actual position of the feeding guide is smaller than the set position, the lock is not formed; if it is larger than the specified position size, because the feeding sheet is too wide and the size of the lock is too bad, the two lock of plates cannot be connected or the material will be wasted; if the feeding guide rail is inclined, it is prone to defects such as uneven front and back width and deviation.

Comifo is a professional ducting machine supplier, we provide auto line duct machine, flange forming machineand etc. Comifo does everything to make you be assured of our most honored service.

Send product request

Other supplier products

| Vertical Duct Seam Closing Machine | Vertical Duct Seam Closing Machine Model No.: VWSC-1600Style: VericalThickness Range: 0.4-1.2mmDuct Length: 1200-1550mmSpeed: 24m/min(78 FPM)Min.Or... | |

| Beading Machine | Model No.: CBM-1.2*1600,CBM-1.2*2000 Max Coil Width: 1600mm,2000mm Thickness Range: 0.4-1.2mm(18-27Ga) Supply Ability: 10 Sets per Month Port: GUAN... | |

| RF-12M LOCK FORMER | COMIFO HVAC MACHINE CO.,LTD specializes in air duct machinemanufacturing, contracting and selling HVAC air conditioning equipments, HVAC machinery,... | |

| Vertical Duct Seam Closing Machine | Model No.: VWSC-1600 Style: Verical Thickness Range: 0.4-1.2mm Duct Length: 1200-1550mm Speed: 24m/min(78 FPM) Supply Ability: 10 Sets per Month Po... | |

| Duct Auto Line Ⅵ | Model No.:CAL5-1.2x1300,CAL5-1.2x1600 Max Coil Width:4'(1250mm),5'(1550mm) Thickness Range:0.5-1.2mm Speed:0-18m/min Shearing Tolerance:±0.5... |