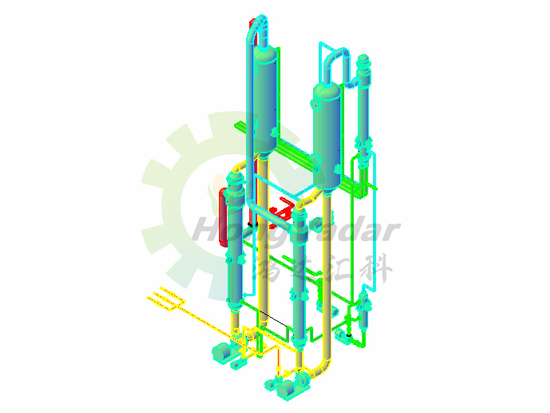

Continuous Evaporative Crystallization System

HVD-CC-T series continuous crystallization equipmentsystem is designed and developed by our factory with patent applied.

Core Of Evaporative Crystallization Process Control

Design enough long crystal time according to crystal characteristics to create an environment conducive to the growth of crystal structure.

Continuous cooling crystallizeradjusts the direction of materials, control the number of microcrystals, realize the whole process control of seed generation, seed growth, elimination of microcrystals, growth of qualified particles, and timely discharge of qualified particles.

Most businesses take crystallization as the process of concentration. It is believed that the concentration reaches supersaturation, the crystal forms naturally, and there is no awareness and measures to control the crystal quality. The control of the crystal purpose is ignored, and the influence of crystallization on separation and drying is not fully considered, which makes the subsequent section treatment more difficult due to the crystallization. Therefore, the purpose of crystallization is to improve the overall yield and product quality and reduce the product production cost by continuous crystallization equipment.

Characteristics Of Evaporative Crystallization System

Crystallisation and evaporationsystem is used for products with general requirements on crystal shape and size and can achieve high concentration discharging.

According to the characteristics of materials and the evaporation capacity, Crystallisation and evaporation system can be designed as a single-effect or multi-effect evaporative crystallization system.

The unique design of the crystallizer can meet the intermittent crystallization, semi-continuous crystallization, and continuous crystallization system. Continuous crystallization equipment can meet the continuous feed, continuous discharge process requirements.

The whole crystallisation and evaporation process system evaporates under the vacuum condition, with relatively low temp, fast evaporation speed, high evaporation concentration, and the relatively high viscosity of the liquid material is not easy to scale or block, which can achieve the maximum crystal ratio under the same energy consumption.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy saving continuous crystallization equipment system for the customer. The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose Chinese GB, International ISO, American standard ASME, European standard PED and other standards for equipment design and production according to their needs.

Continuous Evaporative Crystallization System Technical Parameter

|

Model |

Ev capacitykg/h |

Steam consumption kg/h |

Each effect vacuum, mmHg |

Each effect temp. ℃ |

Steam pres.MPa |

Feed DS,% |

Discharge DS, % |

||||

|

1steffect |

2ndeffect |

3rdeffect |

1steffect |

2ndeffect |

3rdeffect |

||||||

|

HVD-CC1.0-T |

330-400 |

300 |

510 |

750 |

85 |

55 |

5-6(MSG) |

55-65(MSG) |

|||

|

HVD-CC3.0-T |

990-1200 |

||||||||||

|

HVD-CC4.5-T |

1485-1800 |

||||||||||

|

HVD-CC6.0-T |

1980-2400 |

||||||||||

|

HVD-CC9.0-T |

2970-3600 |

||||||||||

|

HVD-CC12.0-T |

3960-4800 |

||||||||||

|

HVD-CC15.0-T |

4950-6000 |

||||||||||

|

HVD-CC20.0-T |

6600-8000 |

||||||||||

Beijing Hongvadar Engineering Technology Co. Isa professional hydrocyclone manufacturers, we provide small scale tomato processing plant, continuous oscillatory baffled crystallizer, circulating liquid evaporator crystallizer, evaporation vs crystallization, continuous crystallisationand etc. For more info about how is crystallization different from evaporation, contact us.

Send product request

Other supplier products

| Fluid Bed Dryer System | HVD-FBD-P series boiling fluidized bed dryer takes air heated by the heat exchanger to form hot air which is distributed into the main engine throu... | |

| Continuous Evaporative Crystallization System | Hongvadar is advanced in many areas, such as being the corn starch production plant and small scale tomato processing plant. HVD-CC-T series conti... | |

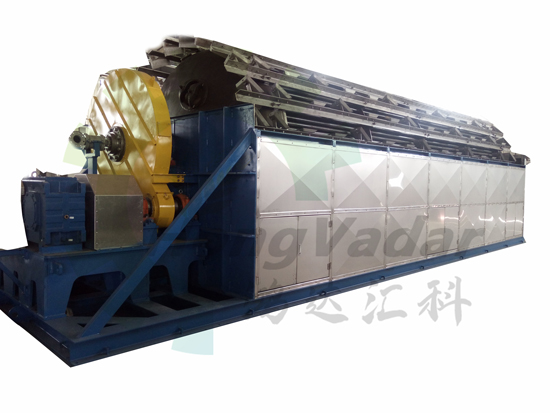

| Bundle Dryer | HVD-BD-P series rotary tube bundle dryersystem is an indirect contact dryer. Its structure is the transmission of heating tube bundle equipment wit... | |

| Air Dryer System | HVD-AD-P series air dryer dehydratorworking system unit is composed of an air heater, air filter, disintegrating disc, thrower, venturi pipe, air d... | |

| Isomerization System | HongVadar Co. abides by the business philosophy of "Take honesty as the foundation and Keep credit to develop", adheres to the practice principles ... |

Same products

| Felt Polishing Wheel Drum | Seller: Keying Abrasives | The steel wool polishing wheelDrum is particularly suitable for polishing larger surfaces. The st... | |

| 7 Inch (180mm) Flap Disc | Seller: Keying Abrasives | KEYING manufactures Self-adhesive Disc, our production is about reprocessing jumbo rolls of SCM, ... | |

| LEN503 Nebulizer | Seller: Lepu Medical Technology(Beijing)Co.,Ltd | Cute pet caring Small atomized particles nebulizer machine for kids Adjustable atomizing cup H... | |

| SINOART Shanghai Co., Ltd. | Seller: SINOART Shanghai Co., Ltd. | SINOART Shanghai Co., Ltd. is a combined industrial & trading company in China, specializing ... | |

| FPQ2W-10/3T20 10kV Pin Insulators | Seller: Guangdong Yufeng Industries Co.,Ltd | The crimping process of polymer pin type insulatorsshould pay attention to the crimping force, co... |