Aluminum Precision Machining Services

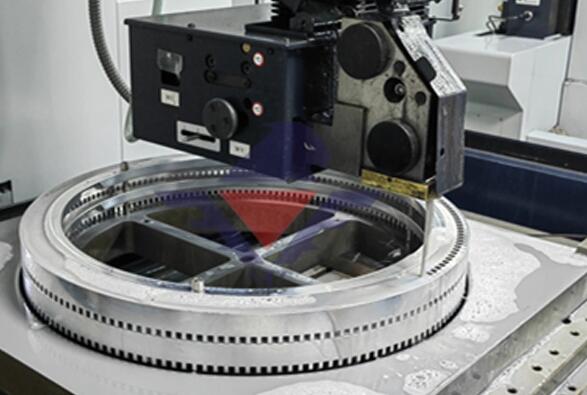

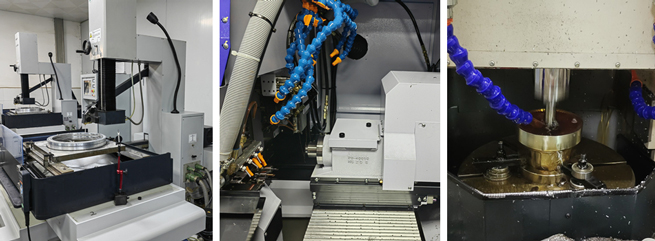

Aluminum CNC Services

Aluminum is a popular material for Swiss machining due to its excellent strength-to-weight ratio, corrosion resistance, and versatility. At Falcon, we utilize Swiss type lathes to achieve incredibly precise tolerances and complex shapes. Our custom aluminum CNCmachining services are highly efficient and cost-effective thanks to the use of advanced equipment and the help of an experienced engineer team.

When producing Swiss machined aluminum turned parts, it is important to choose the right alloy for the specific application, as different aluminum alloys have different properties and characteristics.

Benefits of Swiss Machining Aluminum Parts

Aluminum has a variety of properties and characteristics that make it ideally suited for Swiss machining precision. The following are some of the biggest advantages of working with this material.

What Grade of Aluminum is Best for Machining?

Aluminum offers several benefits in Swiss machining, it allows for efficient production of intricate screw machine components, reduces tool wear, improves precision, and enables cost-effective manufacturing due to its favorable material characteristics. Here are a few aluminum grades commonly used for Swiss machining:

Aluminum 6061

Aluminum 7075

Aluminum 6060

Aluminum 6082

Aluminum 5052

Aluminum 2011

Aluminum 2024

Aluminum 6063

Aluminum 5083

Aluminum 5086

The choice of grade depends on factors such as the specific application, required mechanical properties, machinability, and cost considerations. It's always important to consult with experts to determine the most suitable aluminum grade for your specific Swiss machining project. Contact us to select the grade that aligns with specific requirements and maximizes machining performance.

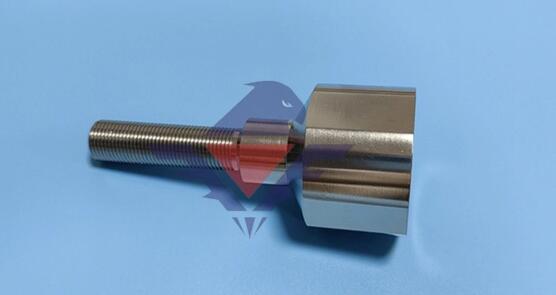

Typical Aluminum Machined Products & Parts

Swiss machining for aluminum materials offers exceptional precision and versatility, making it suitable for many industries and applications. Here are some typical aluminum Swiss machined products and parts:

Aerospace Components: bushings, fittings, brackets, and fasteners

Medical Devices: surgical instruments, implantable devices, orthopedic implants, and diagnostic equipment components

Automotive Parts: fuel system components, sensor housings, connectors, and brackets.

Optics and Photonics Components: lens holders, mounts, reflectors, and light-guiding elements

Consumer Electronics: aluminum enclosures, small mechanical parts, hinges, knobs, and connectors

Industrial Equipment: gears, screws, fittings, couplings, valves, and manifolds

Surface Treatments of Swiss Machined Aluminum Parts

Surface treatments play a crucial role in enhancing the performance, aesthetics, and durability of Swiss machined aluminum parts. They provide various benefits such as corrosion resistance, improved wear resistance, and enhanced adhesion for coatings, and decorative finishes. Here are some common surface treatments used for Swiss machined aluminum parts:

Anodizing: Anodizing is a widely used surface treatment for aluminum parts. It involves creating a controlled oxide layer on the surface through an electrochemical process. Anodizing provides corrosion resistance, increased hardness, and improved dye adhesion for coloring. It also offers a range of finishes, including clear, colored, or hard coat anodizing.

Passivation: Passivation is a chemical process that removes free iron from the surface of aluminum parts. It enhances corrosion resistance by creating a protective oxide layer. Passivation is particularly useful for aluminum alloys that contain iron as an impurity. It can be combined with other surface treatments for optimal results.

Painting and Powder Coating: Painting and powder coating are commonly used surface treatments for aluminum parts when color and aesthetics are important. Both processes involve applying a protective layer of paint or powdered pigment onto the surface, which is then cured to form a durable coating. They provide corrosion resistance, impact resistance, and a wide range of color options.

Besides the above surface treatment methods, there are more surface treatments for machined aluminum parts, including chromate conversion coating, polishing, Teflon coating, plating, etc. The selection of the appropriate surface treatment for Swiss machined aluminum parts depends on factors such as the intended application, environmental conditions, desired appearance, and functional requirements of the parts. It is essential to consider these factors along with cost, performance, and industry-specific regulations when choosing the most suitable surface treatment.

Send product request

Other supplier products

| Micro Machining | Micro machining is a type of manufacturing technique used to produce small and precise parts, components, and structures. This manufacturing proces... | |

| Medical Precision Machining | Medical manufacturing refers to the production and distribution of medical devices, equipment, and supplies used in the healthcare industry. It inv... | |

| CNC Swiss Machining | Swiss machining is a specialized type of precision machining that involves the use of a sliding headstock lathe to produce intricate parts with hig... | |

| Precision Titanium Machining | Precision Titanium Machining Why is Titanium So Hard to Machine? Titanium, as a challenging material, has a unique combination of properties in... | |

| Automotive Precision Machining | Automotive Precision Machining CNC machining technologies are widely used in the automotive industry to manufacture high-quality automotive parts t... |

Same products

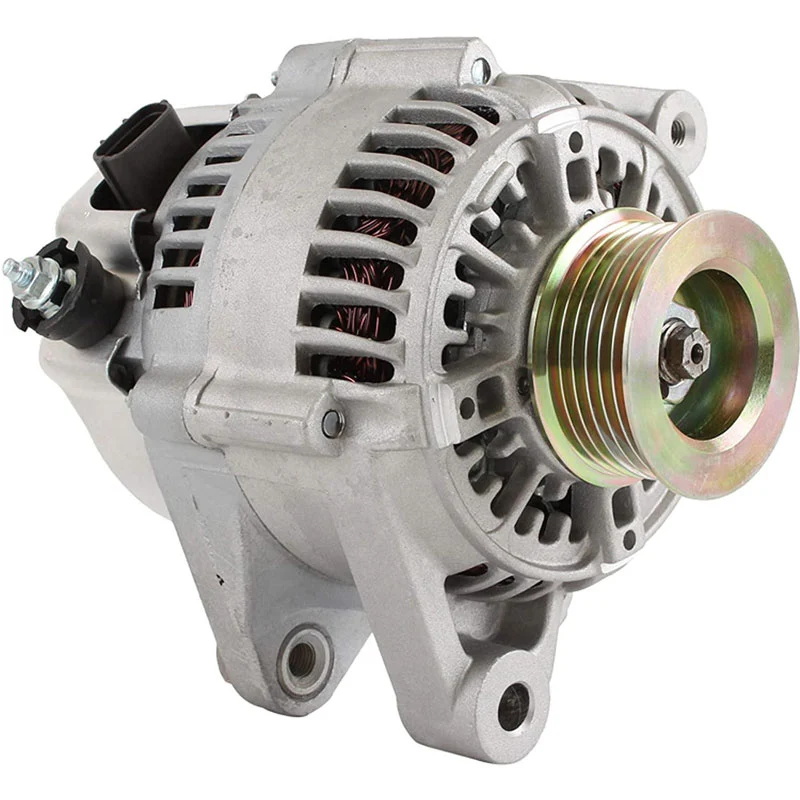

| OEM Car Parts Alternator for Toyota | Seller: Foshan Bohua Auto Parts Co., Ltd | Automobile alternator, which is the main power supply of the automobile, is driven by the engine.... | |

| OEM Parts of Alternator in Car for Toyota | Seller: Foshan Bohua Auto Parts Co., Ltd | OEM Parts of Alternator in Carfor Toyota Automobile alternator, which is the main power supply ... | |

| OEM Alternator Wholesale for Toyota | Seller: Foshan Bohua Auto Parts Co., Ltd | Automobile alternator wholesale, which is the main power supply of the automobile, is driven by t... | |

| OEM Automotive Alternator Parts for Toyota | Seller: Foshan Bohua Auto Parts Co., Ltd | The OEM part number refers to automotive alternator partsspecifically designed for Toyota vehicl... | |

| OEM Auto Parts Alternator for Toyota | Seller: Foshan Bohua Auto Parts Co., Ltd | Auto parts alternator, which is the main power supply of the automobile, is driven by the engine.... |