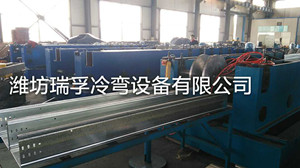

China C&Z shape purlin exchange roll forming machine supplier/production line

General descriptionThe semi-automatic C/Z purlin machine uses one equipment to be possible to produce the C/Z purlin through the manual simple step less regulation different kinds of size, when the size change does not need to replace the forming roller. The production process selects the automatic control method, may according to parameters input purlin length, longitudinal pitch of holes, quantity and so on to carry on the automatic punch holes, the cutting and roll forming.

The C/Z purlin machine consists with the guider, leveler, 2 hydraulic hole punch device, the hydraulic cutting device, fast roller exchange forming machine, the electric controlled system and hydraulic system etc.

The main drive of the whole line uses a reducer with the frequency conversion to control, the speed control, length setting and the localization control are accurate and reliable.

The complete machine contour artistic, production efficiency high, ( the forming speed can reach 20m/min)

Main parameter:1, C/Z purlin size specification:2, Thickness of material: 1.5—3mm3, Distance of punching hole: 45~500mm4, Length: >1.5m5, Max. forming speed: 20m/min

Send product request

Other supplier products

| China Collecting electrodes roll forming machine supplier/production line | Collecting electrodes roll forming machine Production Introduction The line is composed by loading car, uncolier, guiding & feeding device... | |

| China Roof tile roll forming machine supplier/production line | Equipment structureForming machine is composed of decoiler, drive device, main forming machine, cutting device, Hydraulic pressure systme, electric... | |

| China Solar support roll forming machine supplier/production line | Photovoltaic solar support automatic production line, supporting rack profile with many section specification can be produced through switching, pr... | |

| China Cable tray roll forming machine supplier/production line | Cable tray roll forming machine 1, Productionprocessing Uncoiling –leveling- Looping—Feeding—punching —Roll forming&mdash... | |

| China Vane damper roll forming machine supplier/production line | 1, Forming ProcessDecoiler — servo feeder — hydraulic punching device for gap and holes — roll forming device – collection ... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |