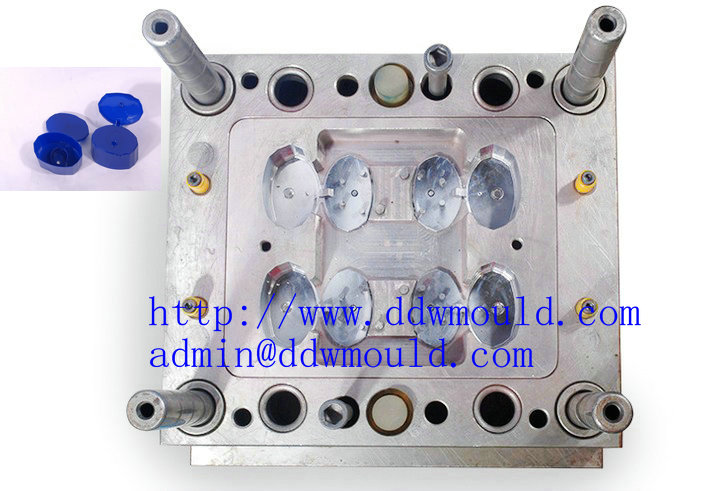

DDW Plastic Cosmetic Bottle Cap Mold Plastic Bottle Cap Mold

Send product request

Other supplier products

| DDW Plastic Chair Mould Plastic Fantastic Furniture Mold | Taizhou Double World Plastic&Mould Co.,Ltd. admin(at) DDW PLASTIC&MOULD is specialized in making Plastic PET Perform Moulds and Plastic... | |

| DDW Aluminium Blow Mould Aviation Aluminum Blow Mold | Aluminium Blowing Mould Aviation Aluminum Blow Mold Taizhou Double World Plastic&Mould Co.,Ltd. admin(at) | |

| DDW Aluminium Blow Mould 7075 Aviation aluminum Blowing Molding | Aluminium Blowing Mould 7075 Aviation aluminum Blowing Mold Taizhou Double World Plastic&Mould Co.,Ltd. admin(at) | |

| DDW Plastic Trash Bin Mold Plastic Garbage Can Mold | TaizhouDoubleWorldPlastic&MouldCo.,Ltd. | |

| DDW 32CAV PET Preform Mold with hot runner no need cutting | TaizhouDoubleWorldPlastic&MouldCo.,Ltd.w |

Same products

| snack food production machine | Seller: Jinan Shengrun Machinery Co., Ltd. | ||

| snack food production machine | Seller: Jinan Shengrun Machinery Co., Ltd. | ||

| GREENMAX Polystyrene Densifier MARS C300 | Seller: INTCO Recycling | GREENMAX Foam densifier Mars series (Hot Melting Machine) is specialized in compacting EPS&EP... | |

| GREENMAX Polystyrene Densifier MARS C200 | Seller: INTCO Recycling | GREENMAX Foam densifier Mars series (Hot Melt Machine) is specialized in compacting EPS Foam and ... | |

| GREENMAX Polystyrene Densifier MARS C100 | Seller: INTCO Recycling | GREENMAX Foam densifier Mars series (Hot Melting Machine) is specialized in compacting EPS&EP... |