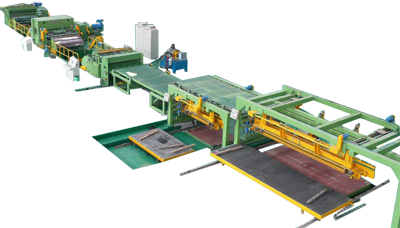

Heavy Gauge Cut To Length Lines

Cut To Length lineChinais a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to length and blanking. RISHBIN supply full range of cut to length line China according to client’s special requirement by combining different component. Every CTL line is engineered and constructed differently for customers, it is customized designed and built, it is considered when choosing a right CTL line about some specifics like production capacity, running speed, material thickness and width, etc. Quality and standard checks are strictly performed on our product before releasing to our valued customers.

Available raw material for cut to length line is hot rolled steel, cold rolled steel, galvanized steel, pre-painted steel, high tensile steel, stainless steel, aluminum, copper, alloys.

The whole line consists of coil car, double support uncoiler, hydraulic pressing and guiding side device, shovel head, pre-leveler, high precision leveler, cut to length machine, stacker, electric control system, hydraulic system, etc. as well as pendulum middle plate and steering device.

Main Technical Parameters of Heavy Gauge Cut To Length Lines

RISHBIN heavy gauge cut to length linesare built for speed and ease of use and can produce higher line speeds without experiencing material slippage. Cut-To-Length Line and Blanking Line will make your job easier, cut costs, and increase your profits.

The lines can be supplied with start-stop shears, flying shears. For start stop shear, the sheet is stopped for each cut of the shear. They can cut a variety of lengths and thicknesses. Electric controls are used to stop the leveler drive after the required length has been fed through the shear and to initiate shear action, then the subsequent feeding of the sheared length to the stacker. For flying shear, it’s a high production solution

Here is working process:

Steel coils are transferred by an entry coil car and loaded onto an uncoiler. From uncoiler the strip proceeds through a five-high precision leveler designed to level steel within the desired material gauge range and yield strength. The strip then proceeds through a squaring unit and precision roll-feed unit to the high speed shear, where it is cut to required length. The cut sheet then moves to float sheet stacker where it is stacked on a pallet and is then moved onto the semiautomatic packaging line for wrapping.

Benefits of Cut to Length lines

Minimal tooling preparations and higher productivity rates

Energy efficient

Reduced operating costs

High in speed and strength

High input and output rates

Extreme sheet flatness due to high precision levelers

Exact cutting accuracy

Send product request

Other supplier products

| Copper Slitting Line | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Cutting Principle for the selection of the Sl... | |

| Light Gauge Cut To Length Lines | Cut To Length line is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leve... | |

| Steel Slitting Line/Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Operating Procedure of Preparatory work befor... | |

| Steel Sheet Slitting Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Metal steel sheet slitting machine main types:... | |

| Stainless Steel Slitting Machine | Are you looking for a professional steel slitting machine manufacturer? Based on much experiences on providing quality, cost-effective and long las... |

Same products

| 3 Axis Glue Dispensing System Robot clutch dispensing Machine for Glue Epoxy Adhesive potting | Seller: 824681 | AB glue meter mix dispensing machine/automatic glue potting machine for LED driver automatic ep... | |

| Automatic Glue Mixing and Potting Machine for LED driver | Seller: 824681 | AB glue meter mix dispensing machine/automatic glue potting machine for LED driver automatic ep... | |

| AB glue meter mix dispensing machine/automatic glue potting machine for LED driver automatic epoxy resin potting machine 2 Part Silicone plyurethane epoxy dosing and dispenser potting machine | Seller: 824681 | AB glue meter mix dispensing machine/automatic glue potting machine for LED driver automatic ep... | |

| Double Liquid AB Adhesive Dispenser Equipment | Seller: 824681 | Double Liquid ABAdhesiveDispenserEquipment AB glue meter mix dispensing machine/automatic glue ... | |

| AB glue meter mix dispensing machine/automatic glue potting machine for LED driver | Seller: 824681 | AB glue meter mix dispensing machine/automatic glue potting machine for LED driver automatic ep... |