Dosing Pump Manufacturer

We provide different dosing pump types and we are always glad to resolve nonstandard and unique tasks. We always take on challenges.

Types of Dosing Pump For Sale

NEWDOSE can provide you with a wide range of high-quality dosing pump chinato meet all your needs. Our featured dosing pumps includes solenoid driven diaphragm metering pumps, motor dosing pumps, ND type mechanical motor dosing pumps, ecodose type mechanical motor dosing pumps, ND electric stroke adjusters.

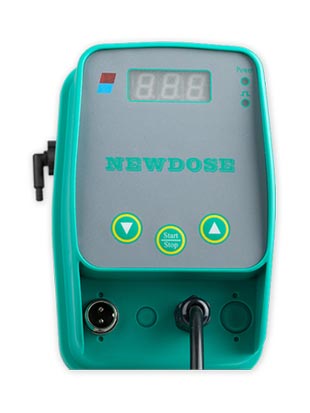

D Type Electromagnetic Solenoid Dosing Pump

Newdose solenoid-driven metering Pump is the perfect solution for small capacity need. It is equipped with LCD display, easy to adjust the fluid delivery proportion.

DFD Type Solenoid Dosing Pump

DP Type Solenoid Dosing Pump

DM Type Solenoid Dosing Pump

DC Type Solenoid Dosing Pump

Motor X Micro-mechanical Motor Dosing Pump

It is the new product, micro-motor driven metering pump, focus on accurate metering at the range of 1-18Lph. Motor X is much lower pulse design and lower noise.

ND Type Mechanical Motor Dosing Pump

Motor driven dosing metering pump are much more powerful and stable, Spring Return Mechanical Diaphragm Pump are widely used in waste water treatment, chenmical, food and industries.

NDJ Motor Dosing Pump

NDWS Motor Dosing Pump

NDWL Motor Dosing Pump

Ecodose Type Mechanical Motor Dosing Pump

Ecodose Type Mechanical Motor Dosing Pump

Using gearmotor, Ecodose is focus on 30~150Lph, which is ecomomic and save cost. The switch button is easier to control. Ecodose can be equipped with float swicth.

ND Electric Stroke Adjuster

As for ND electric stroke adjuster, Newdose can provide you with two types of dosing pumps including remote control electric stroke adjuster and manual control electric stroke adjuster. The adjuster receives an analog signal (4-20mA) and can accurately modify the displacement of the dosing pump.

Dosing Pump Faqs

How to set the pressure of the dosing pump safety valve?

The value of the safety valve should be in the range of the working pressure of the pump, cannot adjust the pressure higher than the max pressure of the pump. If the max working pressure of the pump is 3Bar, the safety valve should be set as 3 Bar, or lower than 3Bar. Over-pressure is one of the reasons that cause the broken of the pump.

What's the float switch of dosing pump and its function?

The float switch is a very important device to control the liquid level of the tank. The float switch can automatically control the start and stop of the pump according to the variation of required liquid level, with no need of a special person to care about, making operation quite easy.

When the level is lowered, the float sinks, and the contact point inside the switch is closed. This contact point can be used to control the metering pump. For example, it can stop the metering pump 1 and start the metering pump 2. On the other hand, it also can indicate that the cartridge is empty by turning on the alarm/indicator light. And the float switch can be applied to the tank to indicate that the tank is full and to stop the metering pump.

What types of dosing pumpdo you offer?

NEWDOSE pump has two types, solenoid driven and motor-driven dosing metering pump, the capacity range is 1~6000Lph.

What are the accessories come with the dosing pumps?

For solenoid dosing pump, there are filter, sprayer, connectors, and pipes in the accessory kit.

The motor-driven pumps don’t be equipped with any accessories. It has to choose the other parts according to the installation situation.

How to select a dosing pump?

Confirm the flow rate of the solution (how much liters of the solution should be transferred in one hour?)

Check the main characteristics of the solution, such as corrosivity, viscosity, concentration, and temperature.

Confirm the pressure of the dosing system.

Confirm the suction height.

Check if the dosing system needs any signal control, such as pulse signal, 4-20mA signal, or RS485.

What's the function of pulsation damper?

To select one proper size of pulsation damper could decrease at least 90% pulse, which makes the liquid flow more stable. Equipped with pulsation damper can help to slow down the accelerated speed of the flow and protect the pump head.

How to adjust the back-pressure valve?

Do not make the pressure value higher than the max working pressure of the pump can hold.

When there is pressure in the suction point, adjust the pressure of the injection point is 1bar higher than the suction point.

Ark Electric & Mechanical Co., Ltd.is a professional dosing pump supplier, we provide automatic metering pump, diaphragm metering pump, etc. Want to buy dosing pumpor know dosing pump cost? Please contact us.

Send product request

Other supplier products

| Metering Pump | Matters Needing Attention When Installing The Metering Pump: The precision metering pump and the motor have an integral structure, and there is ... | |

| Metering Pump | Matters That Needs Attention When Installing The Metering Pump metering pump chinaand the motor have an integral structure, and there is no need ... | |

| Sulfuric Acid Metering Pump | Sulfuric acid is a kind of active binary inorganic strong acid, which can react with most metals. High-concentration sulfuric acid has strong water... | |

| Metering Pump | Matters Needing Attention When Installing The Metering Pump: Operating Procedures Of The Metering Pump: “remote” position. The stro... | |

| D Type Electromagnetic Solenoid Dosing Pump | For more than 19 years, the solenoid driven diaphragm metering pumpare popular and typical of NEWDOSE products, offer a wide selection of flow rate... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |