THE DEVELOPMENT HISTORY OF FRICTION STIR PROCESSING AND FRICTION STIR WELDING

History of Friction Stir Welding

Friction stir processing is a processing method evolved from friction stir welding, also known as friction stir treatment.

The basic principle is that the material to be processed undergoes severe plastic deformation, mixing and crushing through the strong stirring action of the stirring head, so as to realize the densification, homogenization and refinement of the microstructure. Friction stir machining can eliminate defects such as shrinkage porosity and shrinkage cavities in cast products, and can also refine grains, thereby improving material properties.

Friction stir welding technology was invented by the British Welding Research Institute in 1991, and applied for an invention patent in the UK the following year, and applied for patent protection in countries around the world. Since the patent protection and publication, friction stir welding technology has been widely used first and mainly in the field of light metal structures such as aluminum alloys and magnesium alloys and has also achieved certain development in the field of high melting point materials.

In addition to the advantages of ordinary friction welding technology, friction stir welding can also connect various joint forms and different welding positions. Norway has established the world's first commercial friction stir welding equipment, which can weld Al ship plates with a thickness of 3-15 mm and a size of 6x16; It is used to weld certain rocket components; McDonnell Douglas also uses this technique to make the propellant tanks for the Delta launch vehicle.

Nowadays, FSW friction stir welding products include alloy battery tray, water cooling plate, battery cold plate,water cooling solar panels and so on.

Send product request

Other supplier products

| Aluminum Alloy Convection Heater | Heating elements can be selected: aluminium sheet or clay, power 600/900/1500/1800W, power switch, LCD digital screen control or remote control, te... | |

| AUTOMOTIVE PARTS ALUMINUM DIE CASTING MARKET | Aluminum die casting is a process of casting aluminum alloy under high pressure. It is widely used in the automotive industry because of its advant... | |

| Water Cooling Plate | Water/liquid cooling plates use a pump to circulate the coolant in the heat pipe and dissipate heat. The heat absorption part on the radiator (call... | |

| Battery Cold Plate | The main materials of battery cooling plates are aluminium alloy and stainless steel. Due to the requirements of low density and various forming pr... | |

| Die Casting Automotive Parts | In the early stage of product development, the customer only needs to provide 2 D or 3 D renderings or samples in the format of DXF/DWG/PRT/SATIGES... |

Same products

| METALWORKING SERVICES & PRODUCTS IN AGRICULTURAL | Seller: Wuhu Hunkmachining Accessory CO.,Ltd | Agriculture is closely related to metalworking processes. Modern agriculture is extremely effi... | |

| METALWORKING SERVICES & PRODUCTS IN AEROSPACE | Seller: Wuhu Hunkmachining Accessory CO.,Ltd | aerospace metal stampingparts occupy a very important position in aero-engines with their unique ... | |

| METAL WELDING | Seller: Wuhu Hunkmachining Accessory CO.,Ltd | Metal weldingis a manufacturing process and technology to join metals or other thermoplastic mate... | |

| METAL STAMPING | Seller: Wuhu Hunkmachining Accessory CO.,Ltd | Stamping is a cold stamping process, which is to cut, bend or shape the material into the finishe... | |

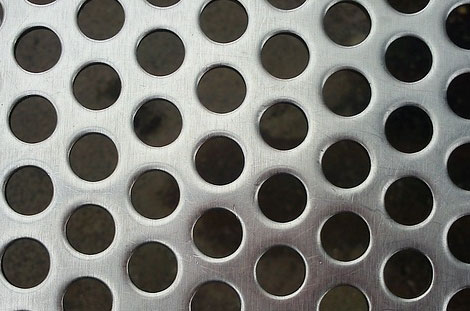

| METAL PUNCHING | Seller: Wuhu Hunkmachining Accessory CO.,Ltd | Metal punching serviceis a key part of Hunkmachining's services, mostly applied to automobile par... |