GS-ZP-600 Induction Annealing Equipment

Produced by: Zhengzhou Gous Electromagnetic Induction Heating Equipment Co.,Ltd

All supplier products

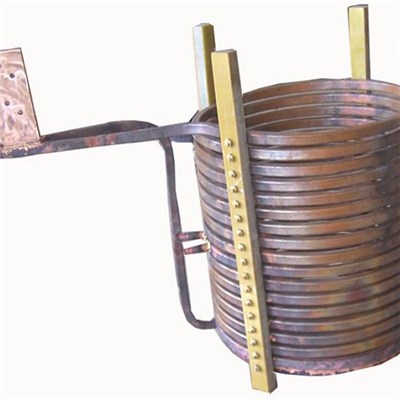

GS-ZP-600 Induction Annealing EquipmentContents:Induction annealing which is a common induction heating application of high-frequency induction heater, is similar method of applying heat to a conductive metal in order to improve ductility. Unlike the other applications, such as heating and forging, the process of annealing concludes a gradually slow heating treatment through gradual cooling.Dominant high-frequency machine is adopted in host computer to control system. Owing the industrial and numerial communication interface, being of standardization, the induction heating equipment can be used to control distance operation and collect data. Induction Annealing which is an induction heating application is a approach of applying heat to a conductive metal in order to improve the metal ductility and relieve its residual internal power. This is one hand. And the other hand about this annealing application of induction heating equipment is to reduce the hardness of the metal. Usually, the recommended temperature of annealing is from 600 to 700.Induction annealing specifically means the process of presenting the metal workpiece to the softest part.Specifications:modelGS-ZP-600Input power600KWInput voltageThree phase 380V /50-60HZOscillation frequency15-35KHZHost configuration dimensions(main) 810×530×1780(part) 500×800×580Advantages:1. The heat is generated directly in the material, leading to high quality and low energy costs.2. It is obviously that the process of this application of induction heater is fast and controllable.3. The heat is definitely crucial to meet the stringent quality standards.Use and Operation:1. Install a suitable induction coil according to the work piece.2. Turn on the cooling water, check the water flow and pressure to ensure that they meet the required range.3. Put through power supply, and different models should be put through the corresponding power supply.4. Open the front panel of the machine, and the control power is put through.5. Place the work piece into induction circle and open pedal switch for heating the work piece.After-sale:Trusted brands of LiPAI and outstanding team of members enable to offer superior manufacturing quality and extraordinary delivery service support. Responsible team of technician is available any time of the day or night and able to provide quick response to our customers wherever they are. And experienced employees give the ability to handle large orders or volume increases while maintaining our commitment to quality, service and delivery. Strong staffs can be qualified to address customers issues and emergencies while they can provide appreciate solutions.

All supplier products

Send product request

Other supplier products

| 16KW Mini High Frequency Induction Heating Machine | 16KW Mini High Frequency Induction Heating MachineContents:16KW mini high frequency induction heating machine is very small and convenient. Its max... | |

| Gold and Silver Melting Machine for Sale | Parameters of Gold and Silver Melting Machine for Sale: Max power: 60kw Oscillating frequency: 30-50KHZ Maximum input current: 150A Input voltage: ... | |

| 46 KW Customized High Frequency Induction Hardening Machine | 46 KW Customized High Frequency Induction Hardening MachineContents:Customized high frequency induction hardening machine is described by the model... | |

| Disc Multi-turn Induction Heating Coil | Disc Multi-turn Induction Heating CoilWhen heating small cylindrical section of the cylindrical surface,For example Φ16mm × 7mm cylindrical surface... | |

| Guide Wheel Quenching Machine Tool | Guide wheel quenching machine toolUsually the guide wheel quenching machine tool is interchangeable with driving wheel quenching machine, just inst... |

Same products

| Digital Blade Sign | Seller: Shenzhen Cosun Sign Smart-Tech Co. Ltd. | Digital Blade Sign The digital blade sign is a product developed from the traditional blade sign... | |

| Pylon Signs | Seller: Shenzhen Cosun Sign Smart-Tech Co. Ltd. | Pylon Signs Pylon signsare a type of upright wayfinding sign used in various facilities within c... | |

| Two-Shot Injection Molds | Seller: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | Seller: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | Seller: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... |