Closed-circuit Cooling Tower

Produced by: Zhengzhou Gous Electromagnetic Induction Heating Equipment Co.,Ltd

All supplier products

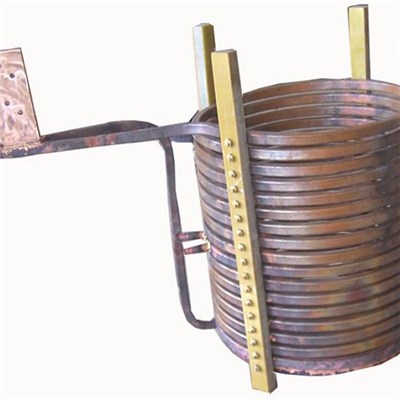

Closed Circuit Cooling TowerPlace of Origin:In Zhengzhou of China. Our induction heating machines are produced in Zhengzhou, which is bounded on the convenient location. Due to the superior situations, such as transportation ,our machines can be conveyed to customers timely in this way.Working Principle:Closed cooling tower is updated and improved on the basic of absorbing the most advanced heat exchange technology. Finally, we developed the heat transfer equipment with high efficiency.After cooling water and air absorbs heat, its temperature rises. The part of the cooling water is vaporized to form water vapor. And evaporation takes away a lot of heat, which is sucked away by the fan into the atmosphere. The water is hot air is trapped in catch basins by drift eliminators; No high-temperature cooling water is vaporized to flow into filler’s heat exchange layer and is taken away the heat to be cooled by the air flowing through. After sufficiently cooled cooling water returns to catch basins, and re-circulating pump sends it into the water distribution system to continue to cycle to work. Dissipated to moisture in the atmosphere is given timely supplement from water float valve of the inside of Catch basins.Applications:Metallurgical machinery, petrochemical industry, silicate industry:1. Closed circulation of blast furnace soft water in ironworks;2. The steelmaking plant furnace, crystallizer, oxygen lance and cooling water system of other devices;3. Cooling water system in steel rolling mill, coking plant;4. Cooling water system of blowers, motors, steel rolling machine and other equipment;5. Cooling water system of medium frequency induction furnace, medium frequency and high frequency power supply and electronic control, melting furnace, heating furnace, hardening furnace, vacuum furnace, induction holding furnace;6. Oil circuit cooling of mechanical processing equipment and grinding tools cooling;7. Internal process water cooling in casting, forging and welding equipment;8. Low temperature-bit oil cooling in oil refining chemical plant, condensing cooling of various oil and gas in the column top, steam and process media condensing or cooling;9. assorted equipment with glass melting pit, monocrystalline or polycrystalline furnace;10. A large injection molding machine cooling system.Civil and commercial aspects:1. Ammonia gas condensing of refrigeration plants, food plants and breweries;2. Equipment supporting with water Source Heat Pump in the high-end central air conditioning system and water-cooled units, etc.Advantages:1. Meeting temperature requirements: Closed circuit cooling tower can achieve heat exchange through air and water partition. The electric heat sensors, SCR, tubes and other electrical components emitted to air emissions. High cooling efficiency and removing accumulated heat meet the temperature requirements of induction heating systems.2. Resolving problems of dirt stains and stoppage: The cooling system uses distilled water to achieve closed cycle with clean water in closed circuit cooling tower and induction heating equipment. In this way, electrical system can be not bothered with dirt stains and blocking scraps for long time.3. Investment costs are significantly reduced: This cooling system doesn’t need dig water pool and purchase water pump and FRP open circuit cooling tower.Working Notes:1. Maintenance requirements of sprinkler system: With the running of closed cooling tower, magazines and other minerals in the water will accumulate in the sink so that you must check water quality regularly. Regularly cleaning up sewage ensure to control quality and prevent scaling best.Spray water quality requirements: "Industrial circulating cooling water treatment design specifications," particularly poor water quality in the area, it should consider the water purification process.2. Drain: When the device is not used, the circulating water pipe should be excluded in order to avoid cold weather damage to the cracking coil.3. Antifreeze issue of closed cooling tower: Antifreeze to prevent spray system. A heater in the spray tank, it generally uses electric immersion heaters;When the system stops functioning, you need to clean emissions of coil water and spray water.After-sale:Trusted brands of LiPAI and outstanding team of members enable to offer superior manufacturing quality and extraordinary delivery service support.Responsible team of technician is available any time of the day or night and able to provide quick response to our customers wherever they are. And experienced employees give the ability to handle large orders or volume increases while maintaining our commitment to quality, service and delivery. Strong staffs can be qualified to address customers issues and emergencies while they can provide appreciate solutions.

All supplier products

Send product request

Other supplier products

| WH-VI-40 Induction Melting Machine | WH-VI-40 Induction Melting machineContents:The melting furnace is a significant part of induction heating equipment. The device is easy to install ... | |

| Disc Multi-turn Induction Heating Coil | Disc Multi-turn Induction Heating CoilWhen heating small cylindrical section of the cylindrical surface,For example Φ16mm × 7mm cylindrical surface... | |

| Cylinder Inner Surface Hardening Inductor | Cylinder Inner Surface Hardening InductorCylinder inner surface hardening generally use scanning quenching. Since the cylinder liner wall thickness... | |

| Promotional Medium Frequency Induction Heat Treatment Machine | Promotional Medium Frequency Induction Heat Treatment MachineContents:Promotional medium frequency induction heat treatment machine is the model of... | |

| Screw Steel Induction Heating Hot-rolled Production Line | Screw Steel Induction Heating Hot-rolled Production LineEquipment Components:Medium frequency power supply, electric capacitance, induction furnace... |

Same products

| Rubber Buoys | Seller: Wuhu Ping\'An Rubber Co., Ltd. | Rubber Buoys At our company, we specialize in offering the highest quality rubber buoysfor marin... | |

| Rubber Boat Flooring | Seller: Wuhu Ping\'An Rubber Co., Ltd. | Rubber Boat Flooring When it comes to flooring on a boat, marine rubber boat flooringis the way ... | |

| Mooring Bollards | Seller: Wuhu Ping\'An Rubber Co., Ltd. | Mooring Bollards Mooring marine bollards provide a secure and reliable way to anchor boats and o... | |

| Ship/Boat Rubber Fenders | Seller: Wuhu Ping\'An Rubber Co., Ltd. | Boat dock rubber fenders are protective devices made of rubber or a similar material that are des... | |

| Port Rubber Fender | Seller: Wuhu Ping\'An Rubber Co., Ltd. | A port fender, also known as a starboard fender, is a type of rubber fender specifically designed... |