Automotive Part

As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy development of automotive mold manufacturers.

In particular, the current independent development and innovation in the automotive parts moldindustry that is being carried out vigorously and in full swing require a strong component system in automotive mold technology co ltd. Vehicle independent brands and technological innovation require automotive injection mold parts and components as the foundation, and independent innovation of parts and components has a strong driving force for the development of the vehicle injection molding automotive parts industry.

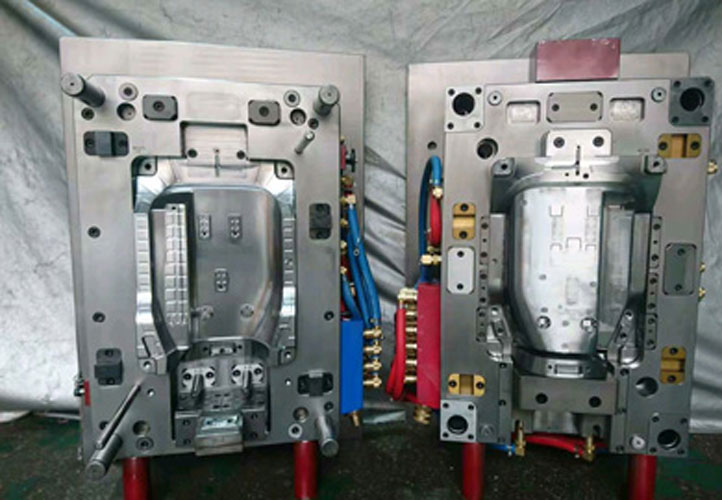

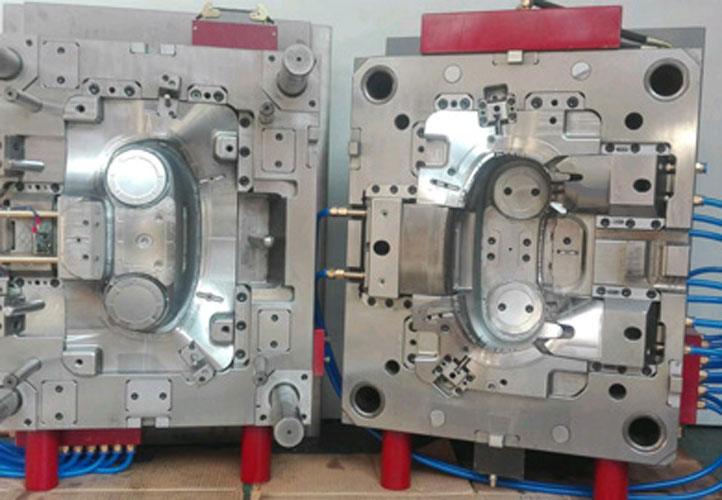

Features of Automotive Injection Mold

Here are three major features of using automotive injection molding for manufacturing injection moulding car parts.

Detailed Features

The automotive plastic injection molding is subjected to extremely high pressure. Therefore, the plastic is pressed harder against the automotive parts mold. This complex and intricate shapes of plastic injection molding automotive parts can easily be designed.

High Efficiency

Once the automotive parts molds have been manufactured to the customer’s specifications, it is very quick to the actual automotive precision plastic injection moulding. The high production output rate makes plastic injection molding automotive parts more cost-effective and efficient.

Enhanced Strength

In automotive plastic injection molding, it is possible to use fillers in the injection molds. This filler reduces the density of the plastic which will enhance strength.

How does Automotive Injection Mold Work?

Automotive injection mold is to first add plastic to the mold, and then the automotive parts mold is continuously rotated along two vertical axes and heated. Under the action of gravity and thermal energy, the plastic in the injection moulding automotive partsmold is uniformly coated and melted, and adhered to the entire cavity of the mold. On the surface, it is formed into the required shape of injection molding automotive parts and is made by cooling and shaping.

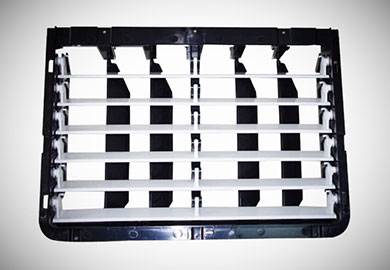

The Specification of injection molding automotive parts

|

Part material |

ABS + PC |

|

Mould Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

A, B, C, plate P20, others 1.1730 |

|

Tooling life |

100W |

|

Mould standard |

HASCO |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Customer satisfaction with mould quality |

95% |

|

FAI pass rate |

99% |

|

Customer satisfaction with project cooperation service |

98% |

GM-TECH is an experienced plastic injection molding factory, we provide plastic parts injection molding, injection molded partsand etc. Contact us to know more about mold technology.

Send product request

Other supplier products

| Injection Moulding Products | GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in th... | |

| Automotive Product Mould | GM-TECH, plastic injection molding manufacturer,has been manufacturing tools for injection molding of plastics for various industries for more than... | |

| Die Casting | GM-TECH, injection molding supplier,has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. W... | |

| Automotive Part | Automotive Part As the foundation of the automotive industry, injection moulding automotive partsare necessary factors to support the sustainabl... | |

| Home Appliance Part | The development and design of plastic injection molding home appliance parts pay attention to safety and health. In-home appliance industry, polypr... |

Same products

| How the financial industry chooses a time synchronization solution | Seller: California Triangle | In the financial industry, time synchronization is an important foundation for ensuring trading, ... | |

| Share the transformation plan of time server | Seller: California Triangle | In the era of rapid technological development, accurate time synchronization is crucial for all w... | |

| 14 inch IP65 i5-1135G7/i7-1165G7 1920*1200 Windows Home rugged laptop | Seller: Shenzhen Sata Computer Equipment Co., Ltd | • Support for Win 10 Home system. • Intel® Core™ i5-1135G7/i7-1165G7, greatl... | |

| Super light and small industrial mini PC support DP display port for advertising | Seller: Shenzhen Sata Computer Equipment Co., Ltd | CPU Intel® Pentium N3700 (Quad Core, Quad thread, Base 1.6GHz, turbo 2.24GHz 2MB... | |

| 7 inch Full IP67 waterproof 1000nits sunlight readable capacitive touch screen monitor | Seller: Shenzhen Sata Computer Equipment Co., Ltd | Panel size 7" Resolution 1024*600 Aspect ratio 16:9 ... |