HAIQ Software Platform

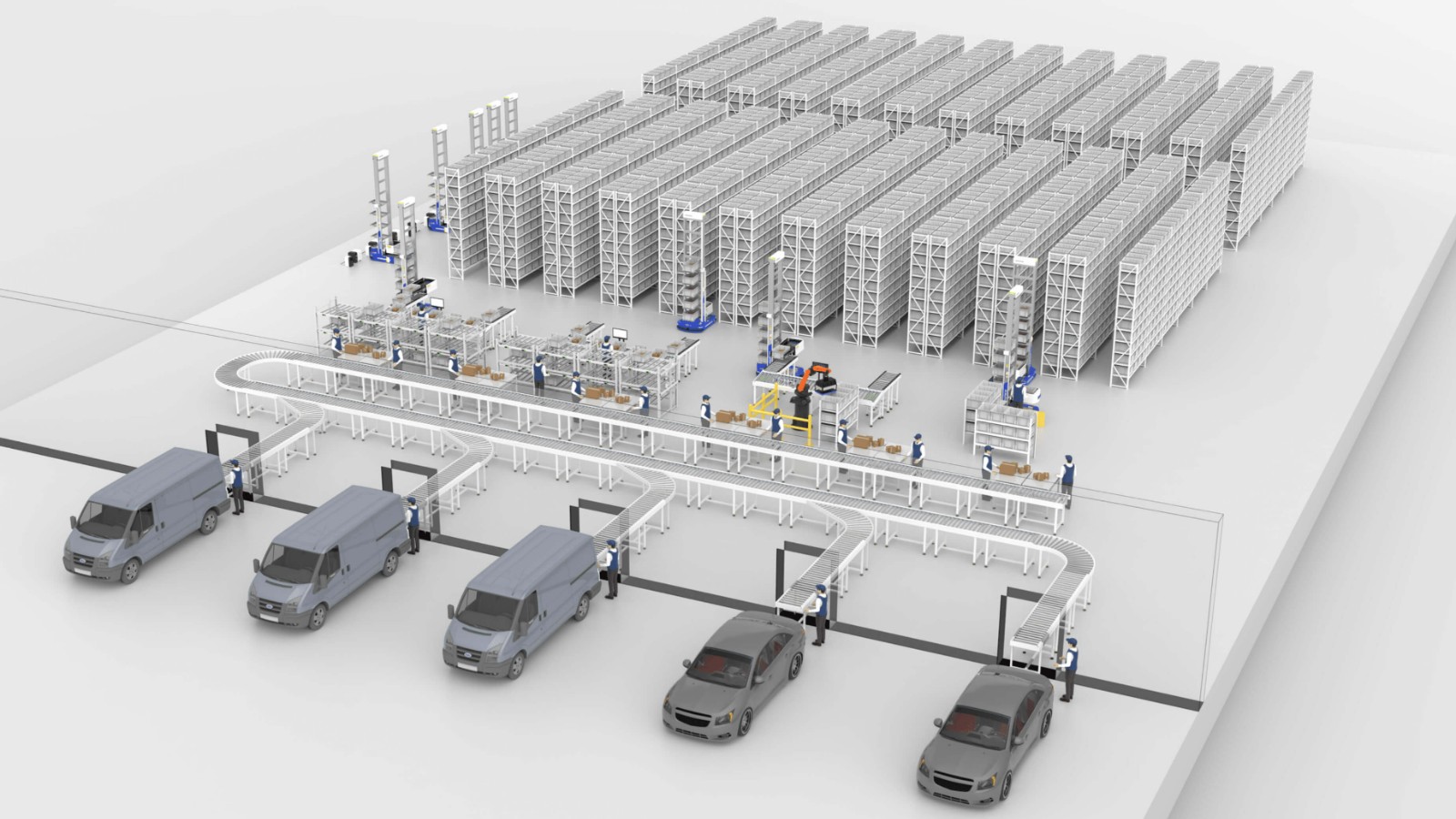

The HAIQ Software Platform is a warehouse management system developed by HAI ROBOTICS based on warehouse automation & robotics. The system introduces the concept of "workstations" and applies "goods-to-person" picking technology. Based on intelligent AI algorithms for real-time scheduling and optimal resource allocation of multiple types of equipment, HAIQ is able to complete inbound, outbound, inventory management, and housekeeping operations.

IWMS: Intelligent warehouse management system

Acting as the HAIQ system's "business conductor", IWMS is in charge of integrating with the customer's management system, offering a variety of functionalities including outbound, inbound, stocktake, and housekeeping through an interactive interface.

IWMS supports the configuration of various business rules such as barcode analysis, task filtering, putaway strategy, and priority adjustment for container movement tasks.

Also, it can be customized according to industry-specific requirements to meet a wide range of customer demands.

* Putaway strategy:

By product: Supports the shipper, commodity type, batch configuration

By case: Supports totes configuration based on rack and warehouse area

* Outbound strategy:

Support the least totes, the shortest distance, priority totes, and other hit strategy

* Stock-taking strategy:

By tote change, discrepancy, rack, and SKU

* Inventory reorganization strategy:

By container volume proportion, empty compartment proportion, case quantity, SKU, etc.

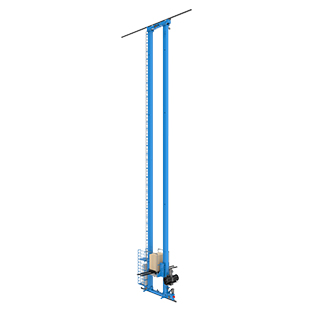

ESS: Equipment Schedule System

As the "hands and feet" of the HAIQ system, ESS receives task instructions from the upstream system and dispatches a variety of resources in the factory or warehouse (such as HAIPICK robots, AGV/AMR, conveyor lines, lifts, etc.) to carry out tasks effectively and intelligently, optimizing overall warehouse operation capacity.

* Quickly integrate third-party equipment:

Integrate and control multi-type automation equipment, such as picking robots, conveyors, PTL, robotic arms, etc.

* Supports mixing of multi-type devices:

Control different types of devices and models(AGV and AMR) at the same warehouse.

* Enabling equipment performed in parallel:

Support mixing multi-type equipment cooperation, split tasks and do not need to trigger serial, such as scheduling ACR and KIVA. Also, ESS can change the priority task and dispatch robots synchronously.

* Supports 600+ equipment operation:

By optimizing system performance and scheduling algorithm, the function of sub-area storage and scheduling equipment is added.

As one of the professional wms software companies, we provide order picking software, smartwarehouse management, intelligent warehouse management system, warehouse management software solutions, smart wms, smart warehouse system, fully automated warehouse system, etc. For warehouse management system costor more information, please contact us.

Send product request

Other supplier products

| Cross-border E-commerce Warehouse Solutions | As consumer preferences become more individualized and varied, cross-border e-commerce is witnessing significant growth, propelled by market forces... | |

| HaiCharger | Hai Robotics provides a one-stop solution, which can customize a complete set of robot charging stationaccording to customer business scenarios and... | |

| HaiPick System Boosts Micro-fulfillment Centers in Europe for Faster Online Orders | The fastest and most efficient way to fulfill online orders has become a top supply chain priority for automated fulfillment centers. The search... | |

| How to Create an Efficient Warehouse Returns Process? | Hai Robotics is committed to helping customers achieve an efficient return process in warehouse. By using our ACR system to optimize the picking, s... | |

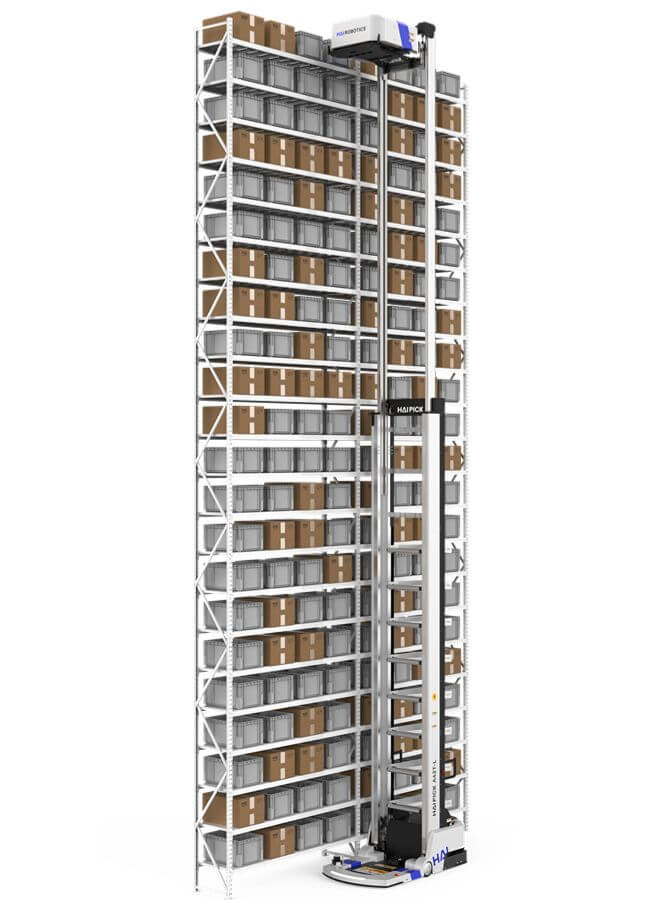

| Telescopic Lift ACR | HaiPick A42T The HaiPick A42T Telescopic Lift ACR is the world's first ACR that can pick and store plastic totes and carton boxes at a dizzying hei... |

Same products

| Pallet Stacker Crane | Seller: Enotek Group | Rated load: 1000kg Max. lifting height: 24m Horizontal acceleration: 0.3m/s² Max. horizontal... | |

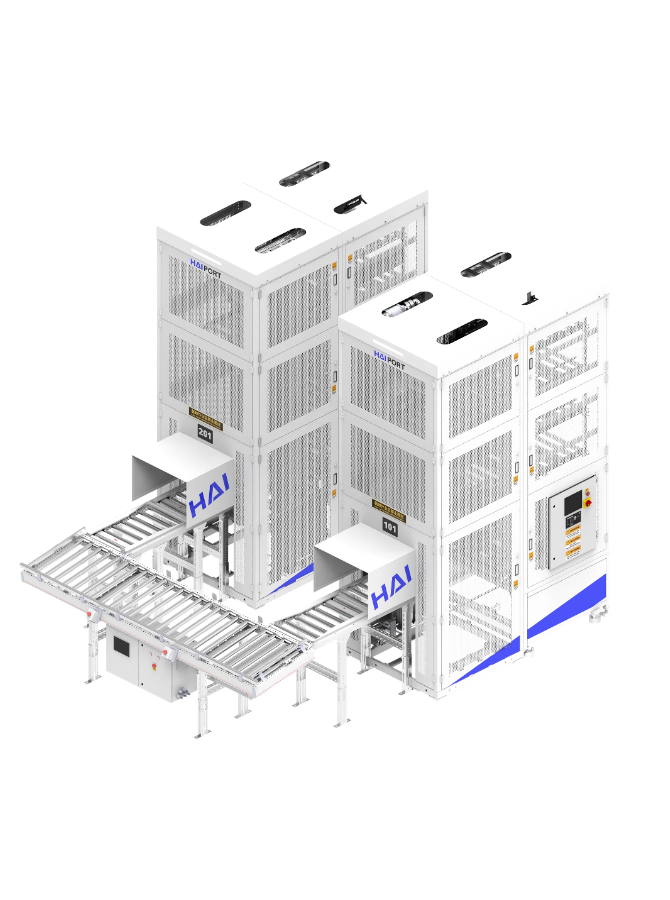

| HaiStation | Seller: HAI ROBOTICS | In the complete Goods to Person solution, HaiPick robots are dedicated to improving transport eff... | |

| HAI Q Software Platform | Seller: HAI ROBOTICS | HaiQ Software Platform HaiQ is an intelligent software platform that leverages AI algorithms to s... | |

| Telescopic Lift ACR | Seller: HAI ROBOTICS | HaiPick A42T The HaiPick A42T Telescopic Lift ACR is the world's first ACR that can pick and stor... | |

| HaiPick A42 | Seller: HAI ROBOTICS | Multi-Layer ACR HaiPick A42 The A42-series offers picking and storage of cases up to a height of ... |