How to choose experimental freeze dryer

How to choose experimental freeze dryer

When purchasing freeze dryer equipment, there are often many problems. From the perspective of users, Beijing Songyuan Huaxing introduced some selection techniques for.

The freeze-drying machine freeze-drying is a method in which a water-containing substance is preliminarily frozen into a solid state, and the water therein is sublimated from a solid state into a gaseous state under vacuum to remove the water and store the substance. The articles obtained by the drying method have the original chemical and biological properties, are easy to be preserved for a long time, can be restored to the form before lyophilization after adding water, and can maintain their original biochemical characteristics, which is a high-quality drying. method. The main uses of modern freeze-drying technology are: freeze-drying storage of in vitro biological tissues; freeze-drying preservation of live bacteria; lyophilization of Chinese herbal medicines, western medicines, biological drugs and blood products; freezing of convenience foods, health foods, functional foods Dry storage and transportation; lyophilization preparation of nano ceramic materials and various metal micropowder materials. Therefore, freeze-drying technology has been widely used in the fields of chemicals, food, materials, medicine, and biological products. Vacuum freeze dryer (referred to as freeze dryer) is a device for realizing freeze-drying technology. It is a complex structure machine involving refrigeration, vacuum, thermal, mechanical, fluid, electrical control and pressure vessels. Know how.

Classification of experimental series freeze dryers:

The performance index of the experimental series freeze dryer is small volume, light weight, multi-function, stable performance, high accuracy of the test system, preferably a multi-purpose machine, which can adapt to the freeze-drying experiment of various materials. The main division methods of the experimental series of freeze dryers are:

1, from the structure

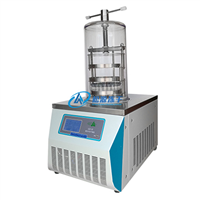

l Bell-type freeze-drying machine: the freeze-drying chamber and the cold trap are separate upper and lower structures, and the freeze-drying chamber has no pre-freezing function. This type of lyophilizer requires manual operation when it is transferred to the drying process after the material has been pre-frozen. Most of the experimental freeze dryers are bell-type, which has a simple structure and low cost. Most of the freeze-drying chambers use a transparent plexiglass cover to facilitate the observation of the lyophilization of the material.

l In-situ freeze-drying machine: the freeze-drying chamber and the cold trap are two independent chambers. The shelf in the freeze-drying chamber has a cooling function. After the material is placed in the freeze-drying chamber, the material is pre-frozen and dried. The process does not require manual operation. This type of freeze dryer has a complicated manufacturing process and high manufacturing cost, but the in-situ freeze dryer is the development direction of the freeze dryer, and is an ideal choice for lyophilization process, especially suitable for medicine, biological products and other special products. Freeze dried.

a, common type b, multi-manifold type c, gland type

2, from the functional points

Ordinary shelf type: The material is bulk in the material tray and is suitable for lyophilization of food, Chinese herbal medicine and powder materials.

With gland type: suitable for the drying of the bottled material of Xilin. When lyophilizing, prepare the material in the vial as needed, float the cap and freeze-dry it. After drying, operate the capping mechanism to compress the cap. It can avoid secondary pollution, re-adsorb moisture, and is easy to store for a long time.

Multi-manifold type: The flask is attached to the outside of the drying chamber, and the material frozen on the inner wall of the bottle is dried. At this time, the flask is connected as a container to the manifold outside the drying box, and the material in the flask is heated at room temperature, and the mixture is heated. The tube switch device can be removed or loaded at any time as needed without stopping the machine.

With pre-freezing function type: material pre-freezing process, cold trap as pre-freezing chamber pre-freezing material, in the drying process, the cold trap is a water trap, capturing the moisture overflowing the material. The lyophilizer with pre-freezing function, the pre-freezing and drying of the materials in the freeze-drying process are all completed on the lyophilizer, and the lyophilizer has high use efficiency, which saves the cost of the low-temperature refrigerator.

Several parameters that should be paid attention to when purchasing a freeze dryer:

1, freeze-dried area

The number in the lyophilizer model represents the lyophilization area of ??the lyophilizer of this model. For example, the lyophilized area of ??the FD-1A-50 lyophilizer is 0.12 m2. The user should calculate the lyophilizer to be used according to his own needs. For example, for each batch of products that require lyophilization of 1.2 kg (liter) of liquid, and loading the material with a material tray, each loaded with 10 mm thick, the load area of ??the lyophilized layer can be calculated:

A (area, m2) = V (volume, m3) / H (height, m) = 0.0012 m3 / 0.01 m = 0.12 m2

A lyophilizer with a laminar load area of ??0.12 m2 is required.

If you have the needs of freeze dryers, freeze dryers, etc., you need to know the quotation, Please go to to find the or : Contact us, we will contact you in the first time.

Send product request

Other supplier products

| Freeze-dried powder freeze dryer | In the beauty and cosmetics market, the active cosmetics freeze-dried powder and freeze-dried mask of the net red are currently popular! Do you kno... | |

| Freeze-drying preservation | The preservation method is to sublimate the bacterial liquid in a frozen state. Finally, a dried sample of the cells was obtained. It also ha... | |

| Food process Freeze Dryer drying process | Food process Freeze Dryer drying process process is divided into two phases, one is the freezing phase, and the other is the vacuum phase (also c... | |

| Freeze drying unit form | Freeze drying unit form The form of the unit is mainly divided into two types, batch type and continuous type. Since batch devices have many char... | |

| LGJ-12 standard type | Thevacuumfreezedryerwidelyusedinmedicine,pharmacy,biologyresearch,chemicalindustryandfoodproduction,etc.Afterthefreezedryingprocess,along term pres... |

Same products

| Loading supervision | Seller: 821678 | CIT-inspection service is one of the leading third party quality control service providers in Chi... | |

| Loading supervision | Seller: 821678 | CIT-inspection service is one of the leading third party quality control service providers in Chi... | |

| CLONED CARDS+ FRESH DUMPS+PIN, | Seller: cardersdrives | Sell Fresh Dumps CCV+FULLZ GIFTCARDS Credit Cards CLONECARDS ALL COUNTRY LIVE 100%Dumps CVV Fre... | |

| AFEN european instant hot cold coffee cup noodle vending machine with coin | Seller: Hunan Aifeng Vending Machine Co., Ltd. | Model AF-60GC4 Name Cup noodle vending machine Capacity ... | |

| AFEN 24 hour self service automatic pharmacy store medical locker vending machine | Seller: Hunan Aifeng Vending Machine Co., Ltd. | Model AF-ZK(22SP)+AF-BLH-19S Dimension H:1940mmW:397mmD:320mm Power AC100V-2... |