What is Low-volume Manufacturing?

Small batch trial production is a transitional link from small trials to pilot tests to industrial production. Prior to mass production, all formal production tooling, processes, equipment, environments, facilities, and cycles are scheduled to produce appropriate small batch quantities to verify product design plausibility and manufacture ability.

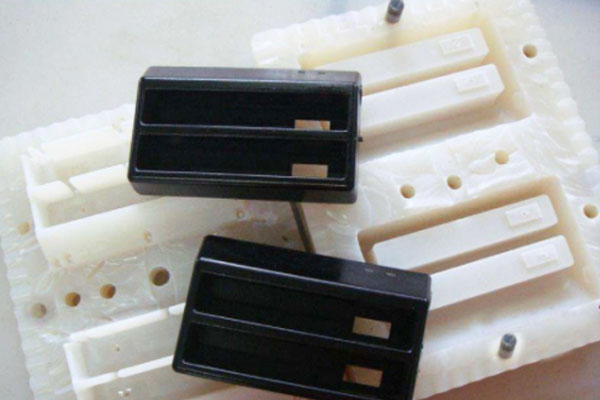

We are professional China printer plastic shell mold manufacturing factory and we have the world's leading SLA 3D printing, CNC machining, vacuum molding, low pressure infusion and other technologies. We also provide one-stop low volume manufacturing servicefrom product design to prototype verification, rapid mold manufacturing to small batch production.

Advantages of Low-Volume Manufacturing

Flexible

Saving cost

Short production period

Efficient and fast

Quality assurance

Meeting the requirements of personalized customization

Applications of Low-Volume Manufacturing

3D printing has a unique advantage in product concept design, prototyping, product review, and functional verification. We could manufacture prototype from CAD digital model directly by SLA, with fast processing speed, short production cycle, no need for cutting equipment and molds. Besides, we it could machine prototypes and molds with the complex structural shapes or being difficult to form by the traditional methods, and the finished prototypes and molds have high precision. 3D printing is applied in the various field, and it could be customized for small batch production.

SLA 3D Printing

RIM technology produce parts by the simple molds, such as aluminum molds, resin molds, and ABS molds. Resin molds are used more commonly, because resin molds are lower cost and the resin molds are manufactured faster compared with the aluminum. RIM technology is suitable for the small batch trial production pf the product development process, which is used in the automotive industry, medical products and instrumental housings, car bumper, car hood, etc. All in all, RIM technology could manufacture small batch production parts with the large and simple structure, and the plastic parts with the uneven thickness.

RIM

The vacuum casting technology uses the prototype of the product to make silicone molds under vacuum status, and adopts materials such as PU, ABS etc. to manufacture parts under vacuum status which is the same as with the prototype of the product. This method is suitable for small batch production especially . It is a low-cost solution to solve experimental production and small batch production during the short time, and it also could meet the functional test of some engineering samples with complicated structure . All in all, the vacuum casting technology is suitable for the simple test and the needs of the conceptual design.

ABOUT DUCH GROUP

As the china rapid prototype suppliers, Duch Group provide customers with competitive solutions such as rapid prototype, mass production, small batch production, 3D printing, mold making, and injection molding. With more than 20 years of extensive production experience in the rapid prototyping industry, it is the world's largest rapid prototyping service company.

Send product request

Other supplier products

| Reverse-Engineered Service | What is Reverse Engineering? Reverse engineering is to obtain the point cloud data of the physical model by using the three-dimensional digital sca... | |

| Vacuum Casting Services | What is the Vacuum Casting? The china vacuum castingtechnology which uses prototype (SLA laser rapid prototyping piece, CNC products) to make silic... | |

| What is 3D Printing Service? | Are you looking for rapid prototype service china? 3D printing technology is a collective term for a series of rapid prototyping technologies, the ... | |

| What is a Mold? | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... | |

| Injection Mould Service | What is a Mold? In industrial production, various types of presses and special tools mounted on the press are used to produce metal or non-metal ma... |

Same products

| UHF High Power dual junction coaxial isolator | Seller: UIY Inc. | 250 to 1300MHz – Dual Junction Coaxial Isolator Design Features Can be Dual Junction or M... | |

| Petroleum Valve Casting CoreTech Series | Seller: Qingtian Baoli Casting Co., Ltd. | Petroleum Valve Casting CoreTech Seriesoffers a steady foundation for producing valves used in fl... | |

| iFixes iG13 Electric Dispensing Gun | Seller: PHONEFIX technology Co.,Ltd | iFixes iG13 Portable Electric Glue Dispenser compatible with 5CC/10CC/30CC/50CC Tube for dispensi... | |

| Bathroom Bi-stable Sensor Faucet Solenoid Valve | Seller: Zhejiang Fuxin Electrical Technology Co., Ltd. | The Bathroom Bi-stable Sensor Faucet Solenoid Valve is designed for use in sensor-controlled syst... | |

| Wear-resistant carbide guide wheel guide roller | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable p... |