Light pole powder

Introduction

Accurate selection of powder has always been a problem for the powder industry. To solve this problem, we name the powder according to the industry’s requirements for powder coatings. We select materials for different industries and make corresponding adjustments to the process to better match the industry’s requirements. We provide customers with high-quality and low-cost products that are easy to use.

| Product name | Light pole powder | ||

| Applicable industries | Light poles, communication poles, and other hot-dip galvanized workpieces | ||

| Powder specific gravity | 1.2-1.8ɡ/cm³ | ||

| Product features |

|

||

| Physical properties | Bending | ASTM D522 | Passed-curvature diameter is 5mm. |

| GB/T1731 | Passed-curvature diameter is 2mm. | ||

| Dry adhesion | ASTM D3359 | Passed-result is 5B. | |

| ISO 2409 | Passed-result is 0 grade. | ||

| GB/T9286 | Passed-result is 0 grade. | ||

| Cupping | ISO 1520 | Passed 5mm-No cracking or shedding of coating. | |

| GB/T9753 | Passed 5mm-No cracking or shedding of coating. | ||

| Impact resistance (positive impact) | ASTM D2794 | ≥50kg.cm | |

| GB/T9753 | 50kg.cm | ||

| Pencil hardness (scratch hardness) | ASTM D3363 | ≥H | |

| GB/T6739 | ≥H | ||

| Storage stability | 12 months (less than 30℃ environment) Re-test after expiration. If it meets the requirements, it can be used at will. | ||

| Curing process | 200℃/12min, 180℃/15min (workpiece surface temperature). | ||

| Pretreatment | All metal substrates need to be degreased and degreased, iron metals are treated with zinc or iron phosphating and aluminum chromium to improve corrosion resistance. | ||

| Coating |

|

||

| Damage repair | Surface treatment: Grinding + air cleaning.

Application: Recoating mode,reduce spraying voltage. |

||

| Safety Warning |

|

||

| Disclaimer | Important note: The information provided in this table cannot be comprehensive and is based on current laws and current knowledge. Anyone who intends to use the product in areas other than those recommended in this table without first obtaining written confirmation from us of the product’s suitability will bear the consequences. It is the user’s unshirkable responsibility to take necessary measures to meet local legal and regulatory requirements. Please continue to read the material safety data sheet and technical parameter sheet of our products when you have time. We try our best to ensure that all the instructions for our products (in or outside the table) are correct, but we cannot fully control the quality or condition of the substrate and the many factors that may affect the use of the product. Therefore, unless we specifically confirm in writing, we do not assume any responsibility for loss of product performance and any other loss or damage caused by the use of the product. All products and technical recommendations we provide are subject to our standard terms and conditions of sale. Please obtain a copy of this document and read it carefully. The content of this table will be supplemented and improved as we accumulate experience and update policies. Before using the product, the user should verify whether the data in this table is the latest. | ||

If you're ready to take the next step or Request Free Samples, Leave your message below and we’ll reply soon. 20+ years of chemical manufacturing & export experience, a partner you can trust.

Send product request

Other supplier products

| Thermosetting flat powder coating | Product Introduction MT thermosetting flat powder coating adopts advanced polymer formula technology to form a dense and smooth coating through hi... | |

| Polyamide Powder Coating for Building Materials | We supply a complete range of polyamide (nylon) powder coatings, including Nylon 6, 11, 12, and 1010, designed for demanding applications requiring... | |

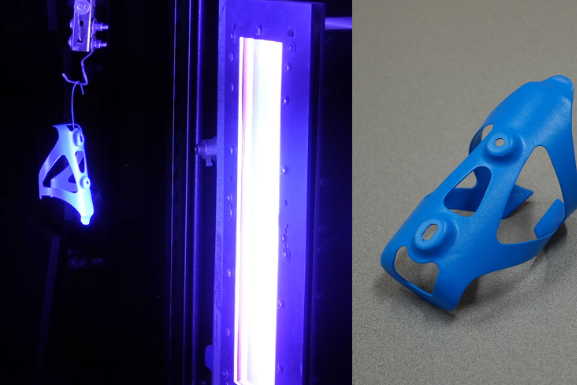

| UV-Cured Powder Coating | UV-Cured Powder Coating How can we coat heat-sensitive substrates effectively? UV-cured powder coatings provide the solution. Unlike traditional c... | |

| Polyester based powder coating MT-JA020G White | Product Description MT-JA020G is a polyester based powder coating, formulated using TGIC and is designed for exterior exposure offering excellent ... | |

| Gradient Powder Coating | We are a professional powder coating manufacturer with over 20 years of export experience, specializing in customized gradient powder coatings for ... |

Same products

| Trimellitic anhydride 97% | Seller: Yufeng International Group Co., Ltd | Trimellitic anhydrideis a 2-benzofuran compound having oxo groups at the 1- and 3-positions and a... | |

| Isobutyric Anhydride CAS 97-72-3 | Seller: Yufeng International Group Co., Ltd | Product Name: Isobutyric Anhydride CAS No.: 97-72-3 Purity: 99% Molecular Formula: C6H10O3 Mo... | |

| Isobutyric Acid CAS 79-31-2 | Seller: Yufeng International Group Co., Ltd | Product Name:ISOBUTYRIC ACID Synonyms: 2-Methylpropanoic acid 79-31-2 Isobutanoic acid 2-Met... | |

| 2-Amino-2-methyl-1-propanol(AMP)CAS:124-68-5 | Seller: Yufeng International Group Co., Ltd | AtYufeng, a trusted 2-Amino-2-methyl-1-propanol Factory & Supplier, we prioritize quality and... | |

| Dimethyl sulfoxide (DMSO) CAS: 67-68-5 | Seller: Yufeng International Group Co., Ltd | Yufengis one of the leading dimethyl sulfoxide suppliers and also a professional such manufacture... |