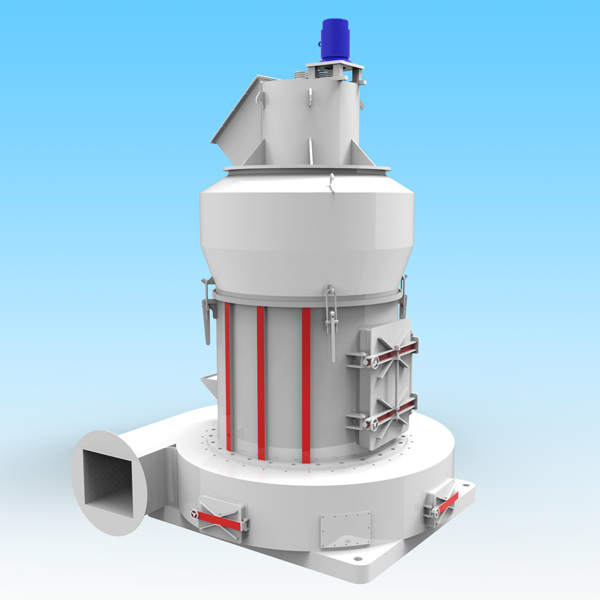

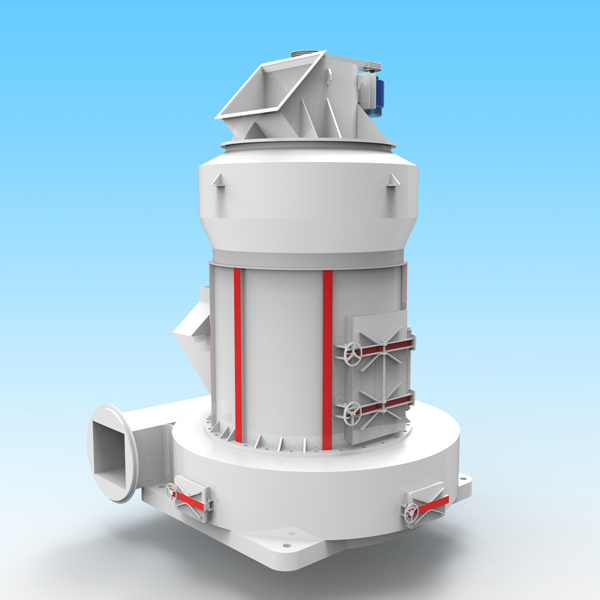

GKW970 Micro Powder Mill

GKW970 Micro Powder Mill is a new modified superfine powder mill developed by our R&D team for grinding 400-1250 mesh powder based on client’s need.It is mainly used for grinding non-flammable and non-explosive materials, whose hardness below seven Moh's hardness following humidity below 6%, such as dolomite, calcite, marble, barite, limestone etc. As the top option of grinding 400-1250 mesh powder, CKW micro powder mill is featured with high capacity, wide application, energy-saving, easy operation. Its total installed power is 132KW. If grinding calcite, the capacity is 1.5 t/h for 1250mesh powder.

Technical & Structural Benefits of GKW970 Micro Powder Mill:

1. Finished particle size 400 mesh -1250 mesh (stepless adjustment);2. Breakthrough hard materials and powdery materials, and grind the materials such as talc and fly ash;3. Low cost of equipment wearing parts;4. Convenient equipment maintenance, maintenance & replacement of wearing parts;5. Low energy consumption and high output, for users to create better economic results;6. Energy conservation and environmental protection.

|

Model |

Max Feeding Size |

Product Fineness (mash) |

Capacity |

Total Installed Power |

|

GKW970 |

≤10mm |

400-1250mesh |

500-3200kg/h |

120kw |

|

GKW1270 |

≤10mm |

400-1250mesh |

1000-6500kg/h |

225k |

Safe Regulations for Operation of GKW970 Micro Powder Mill:

(1) Persons who are familiar with the machine's instruction book and its characteristics are permitted to operate it.(2) Strick shift system is required.It is necessary to have recording book that machine's operation (including running and lubricating the machine, temperature increase at all various parts and seal etc.), output per shift, product quality, voltage, current and the arising fault etc. Should be registered in detail.(3) Starting and stopping must be carried out strictly depending on the regulations in Chapter "Applications".(4) Working place must be kept tidy and clean.No piling is allowed in theroom.After working finished, the machine should be stopped and its surface is wiped clean by each shift.(5) Repairing, refilling and wiping are forbidden while the machine is working.(6) Working with the fault is not allowed.The machine must immediately stop down for maintenance once troubles are found.Re-starting is only allowed after repair.

Send product request

Other supplier products

| GK2150 Raymond Mill | GK2150 Raymond Mill Technical & Structural Benefits: This High Pressure Suspension Millhas high output, high-efficiency, and energy saving. It ... | |

| GK-PSH Type Water Spray Dedusting Lime Slaker | GK-PSH Type Water Spray Dedusting Lime Slaker Model: A type C typeE type based on different lime slaker capacity GK-PSH Type Water Spray Dedusting... | |

| GK-PSH Type Water Spray Dedusting Lime Slaker | GK-PSH Type Water Spray Dedusting Lime SlakerModel: A type C typeE type based on different lime slaker capacity GK-PSH Type Water Spray Dedusting ... | |

| Raymond Mill | As national powder R&D center, GUIKUANG has made much efforts and contributions for the development of powder industry more than 40 years. Raym... | |

| GK1720A Pendulum Grinding Mill | GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design. Technical & Structu... |

Same products

| CNC Cylindrical Grinding Machine MA2060/MP2060 | Seller: Lecn Anhui Co., Ltd | Product Description Provide a complete solution for cylindricaland end face grinding of shaft ... | |

| Inner Race Groove Grinding Machine QMB125 | Seller: Lecn Anhui Co., Ltd | product description with one-time clamping and processing of multiple BJ groove, 20-65 mm proc... | |

| Wafer Back Grinding Wheel | Seller: Henan E-Grind Abrasives Co., Ltd. | E-Grind BackGrinding wheels have developed the technology to combine diamond and bond to meet you... | |

| Vitrified Bond Grinding Wheels | Seller: Henan E-Grind Abrasives Co., Ltd. | The diamond and vitrifiedCBNare held in place by ceramic components that are fused to form the ab... | |

| Resin Bond Grinding Wheels | Seller: Henan E-Grind Abrasives Co., Ltd. | Resin bonded grinding wheelsare generally divided into resin bond diamond grinding wheels and res... |