Wireless Transmission Steel Bar Ultrasonic Flaw Detector

Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external defects of various steel bars.

The principle of UT ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel rod by water, the incident propagation will case ultrasonic reflection when there is a defect in the bar. The ultrasonic instrument will alarm the ultrasonic reflected signal after the amplified signal to realize the automatic detection of the defect.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector Brief Introduction

There are two probe regulators in section 1,180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, and the transverse wave incident clockwise.

Detection of defects: detection of round subcutaneous defects in a rounded clockwise direction

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each set consisting of 2 combined wafers, which are evenly distributed in the circumferential direction of the workpiece, 180° apart, on the same section. A total of 4 independent channels.

A total of 2 probe adjustment frames are placed on section 2, each separated by 180°, and a 2-channel combined ultrasonic line focusing probe is arranged on each adjustment frame, and the longitudinal wave is incident.

Detection of defects: metallurgical defects inside the steel bar,

Detection range: center transverse hole.

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each consisting of 2 combined wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, 180° apart, and there are 4 independent channels in the same section.

A total of 2 probe adjustment frames are placed on section 3, each separated by 180°, and a 2-channel combined ultrasonic line focusing probe is arranged on each adjustment frame, and the transverse wave is incident counterclockwise.

Detection of defects: counter-clockwise detection of round subcutaneous defects

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each consisting of 2 combined wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, 180° apart, and there are 4 independent channels in the same section.

Defect detection standard

GB/T4162-2008 Ultrasonic testing method for forged steel bar.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector Parameters

|

Channel number |

12 channels |

|

Flaw detection speed |

30m/min |

|

Total gain |

100dB,step0.5dB |

|

Working mode |

Single probe transmitting, receiving or double probe transmitting and receiving respectively |

|

Sensitivity margin |

≥50dB |

|

Resolving power |

≥26dB |

|

Dynamic range |

≥30dB |

|

scan range |

0~5000mm |

|

Frequency range |

|

|

Sampling range |

250MHz |

|

Repetition range |

Single channel100Hz~4KHzadjustment |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection mode |

Full-wave, positive half-wave, negative half-wave |

|

Gate setting |

Each channel has three gates, A and B are defective gates and C are interface tracking gates. |

|

Alarm indication |

Color Display and Sound Alarm of A, B and C Gate Alarm on Each Channel |

|

Delayed alarm |

Two path,delay time 0.1-10s,step 0.1s |

|

Waveform storage, unlimited number, waveform playback, printing and report generation. |

|

BKNis a professionalmfl suppliers. We provide Eddy Current Testing, Magnetic Flux Leakage Testing, ndt device, ndt testing, ultrasonic metal testing equipment, ultrasonic bar testing, ultrasonic metal testingand so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Magnetic Flux Leakage Testing Equipment | What Is Magnetic Flux Leakage Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leaka... | |

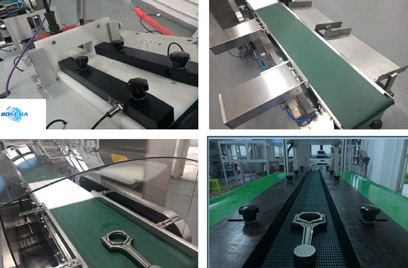

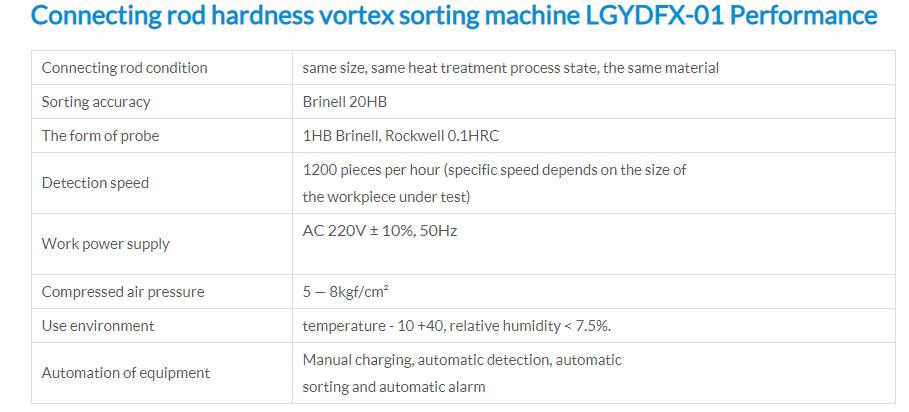

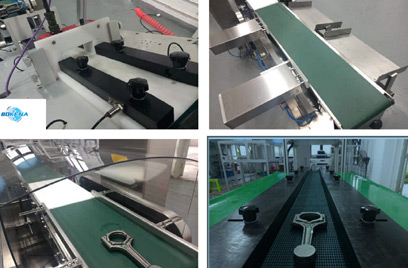

| Connecting rod hardness vortex sorting machine LGYDFX-01 | The connecting rod hardness eddy current testing machine has a calibration device, input compensation parameters, automatic/manual temperature comp... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... | |

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing(BKNET-101) is a fully automated eddy current inspection system that uses large-scale imported integrated circuits combined... | |

| EDM Notch | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |