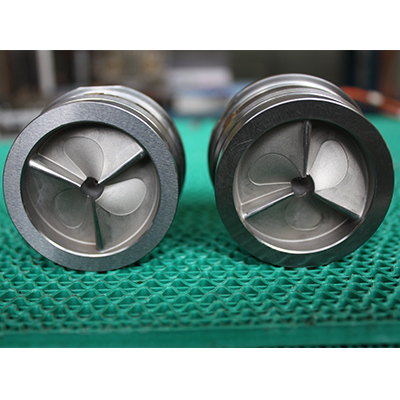

3 Plate Mould 49113-21

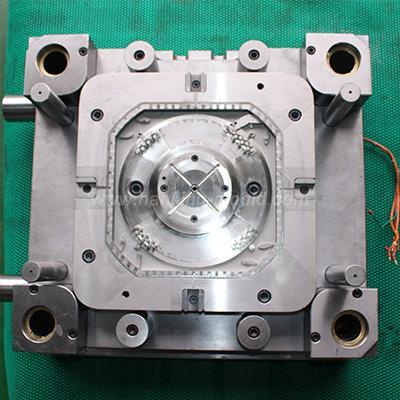

Mould Name: 3 plate injection mold

Part Material: PBT GF15

Product Size: ф34.9x82.29

Product Description: Mischschraube kpl

Mould Cavity: 2 Cavities

Mould Size: 250*230*350 MM

Mould Cavity Steel: 2343 ESR

Mould Injection System: 3-Plate point gate

Mould Ejection System: Round ejector

Mould Cycle Time: 28's

Mould Life Cycle: 500,000

Lead Time: 45 working days

Mould Features: insert molding

3 plate mouldis also called pinpoint gate mould.

There are two parting surfaces to divide the mold into three parts. Compared with the two plate mold, the gate plate of three plate mold is added. It is suitable for the molds that do not allow gate marks around the product. This type of mold uses a pointed gate, so it is called pinpoint gate mold.

The typical 3 plate mould movement process

The mold opening process: the three-plate mold has two parting processes, the first between the stripping plate and the cavity plate, and the second time between the cavity plate and the core plate. When the core side is pulled by the injection molding machine, as the A and B plate are equipped with a latch lock, and there is no connection or obstruction between the stripping plate and the A plate (in most cases, the pull rod is also equipped with a spring) At this time, the stripping plate is first separated from the cavity plate by the pulling force, and the cavity plate moves backward with the core plate. When moving to the set distance, it is blocked by the pull rod limiting block, because the A plate continues to move with the injection molding machine. Therefore, the pull rod is also driven, and the pull rod drives the stripping plate to move to the next set distance and then the pull rod and the cavity plate stops moving.

The injection molding machine continues to move backward, as the pulling force continues to increase, exceeding the locking force of the latch lock, the A plate is separated from the B plate, and stops when the set distance is reached.

The ejector plate drives the ejector mechanism (the ejector pin, the ejector rod, and the lifter) to start the ejection movement, and the finished product is ejected (automatically dropped or removed by the robot).

Clamping process - When there is a pullback mechanism on the ejector plate, the ejector plate is forcibly pulled back by the injection molding machine before clamping.

Under the push of the injection molding machine, the core moves forward to the cavity side, if the ejector plate is not pulled back in advance, the return pin first contacts the cavity plate. Under the reaction force, the ejector plate is returned by the return pin.

The B plate is pressed against the A plate and the stripping plate, and finally completely tight. The nozzle on the injection molding machine is closely fitted with the nozzle bushing on the mold, and the next cycle of injection molding is started.

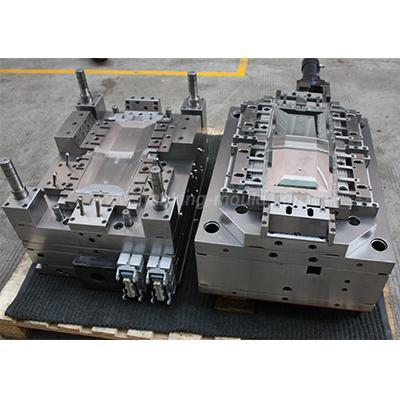

HanKing Mouldis a professional two shot moulding ltd, we provide custom plastic injection molding china, plastic molding, mold 3 plate, plastic plate mould, three plate mould workingand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Industrial Mould | Industrial mouldsis not a mold technology process, but a type of mold that is distinguished from the purpose of use. Generally speaking, products... | |

| Industrial Molding Parts | Industrial Molding Parts Industrial moulding parts are referred to the plastic parts of industrial precision molded products, we preferred to thin... | |

| Precision Mould | ABS Mold ABS full name Acrylonitril Butadiene Styrene copolymer, with excellent comprehensive physical and mechanical properties, excellent low tem... | |

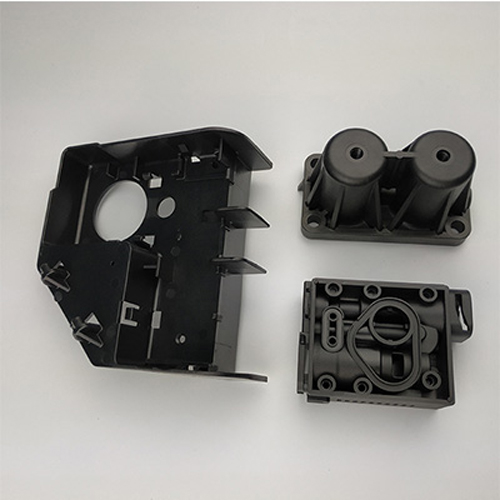

| Consumer Parts Plastic Mold | Description of Consumer PartsPlastic Mold: Plastic Valve 3 Plate Mould Tolerance: +-0.01mm Surface: SPI A2 & VDI 3400 Part material: PPO foo... | |

| 2K Mould | Unscrewing Mould Mould Name: Unscrew Cap MouldPart Material:PP+TPEProduct Size: Product Description: Mould Cavity: Mould Size: 750*810*700mmSuitabl... |

Same products

| YC160W Wheel excavator YC160W | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | 卖方: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |