Aluminum Stamping

Aluminum alloy stamping refers to stamping hardware made of aluminum alloy.

Orienson's Aluminum Stamping

Aluminum alloy is the most widely used non-ferrous metal material in the industry. It has the advantages of low density, high strength, good plasticity, etc., and also has strong electrical conductivity, thermal conductivity, corrosion resistance, and solderability. The metal stamping parts made of it are indispensable and important parts in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, and chemical industries.

Types Of Surface Treatments For Aluminum Stamping Parts

Anodic oxidation can effectively make up for the lack of surface hardness and wear resistance of aluminum stamping parts, thus the stamping parts can have a more beautiful appearance and obtain a variety of colors through anodic oxidation.

Common drawing methods include thread, disorderly lines, spiral lines, straight lines, etc. After the drawing process, the surface of aluminum metal stampingparts has clear micro marks, showing a good visual effect on the appearance.

Types Of Surface Treatments For Aluminum Stamping Parts

Sandblasting for aluminium stampingparts has the effect of removing surface burr and oil, which can improve the surface finish by controlling the surface roughness of the material, as well as improve the adhesion of the surface coating of the stamping parts to make it more beautiful and durable.

Polished aluminum stamping chinaparts can be close to the mirror effect, improve the grade and beauty of the product, but will reduce the durability of the parts.

Benefits of Aluminum Stamping

The density of aluminum is 2.7, about 1/3 of that of copper (8.9) or steel (7.8). For space aircraft, ships, vehicles, and other vehicles and buildings, lightweight is very beneficial, but also can save moving costs and processing costs, reduce costs, It is widely used in the construction industry, civil industry, and other fields.

Good Corrosion Resistance of Aluminum Stamping

Good Corrosion Resistance, Weather Resistance

Aluminum and aluminum alloy in the atmosphere can form a hard and dense layer with the good corrosion resistance of oxidation film, by means of anodic oxidation, electrophoretic coating, powder spraying, and other surface treatment, we can further improve the corrosion resistance of aluminum.

Good Decorativeness of Aluminum Stamping

Good Decorativeness

Because of its good plasticity, aluminum alloy can be processed into various sizes of products, it is ornamental and decorative on appearance with different colors of the film layer.

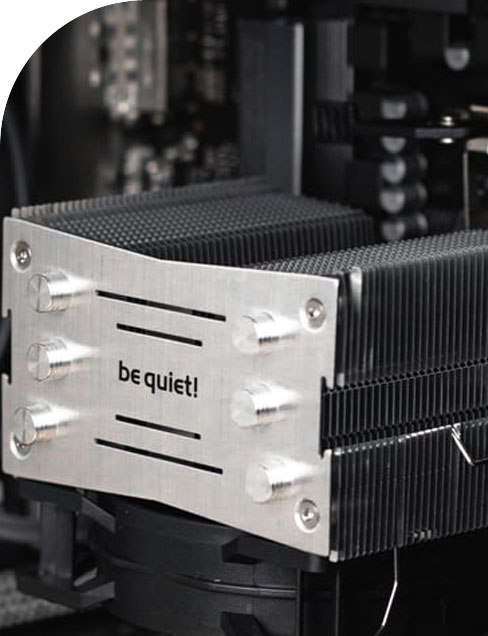

Good Thermal Conductivity of Aluminum Stamping

Good Thermal Conductivity

The thermal conductivity of aluminum is very high, 3 times that of iron, only second to silver, gold, and copper in metal. Therefore, aluminum alloy is a good material for making radiators and heaters.

Application Of Aluminum Stamping

Aluminum Stamping Design

High repair rate, high scrap rate is still the main difficult problems In the production process of aluminum stamping parts in the industry. At present, the main pain points in production focus on necking cracking and material chips. Combined with nearly twenty years of production and maintenance experience of hundreds of types of aluminum stamping parts.

We have had many experiences and measures to solve the common problems of neck cracking and material chips in the production of aluminum stamping parts from the molds, stamping equipment, raw materials, technology, production testing.

As a professional metal stamping supplier, we provide metal stamping, metalwork and stamping, stamped aluminum panels, stamping aluminum, cnc machiningand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Edge Rolling Parts | Edge rolling, we can also call it bending roll round, which is a method to put the sheet metal bending into the nearly closed cylinder forming. It ... | |

| Single Die | A single dieis generally composed of one or more concave dies and a convex dies, which refers to completing the process in a stamping stroke only i... | |

| Deep Drawing Parts | Deep drawing molding is a stamping processing method that uses the die to shape the flat blank into an open hollow part. Orienson's Deep Drawing P... | |

| Optical Fiber Communication Metal Stamping | Orienson is dedicated to helping our customers leverage the power and speed of optical fiber communications. Our high-quality products meet the inc... | |

| Electroplating Service Of Metal Stamping | Electroplating is the process of using electrolysis to attach a layer of the metal film to the surface of metal or other materials so as to prevent... |

Same products

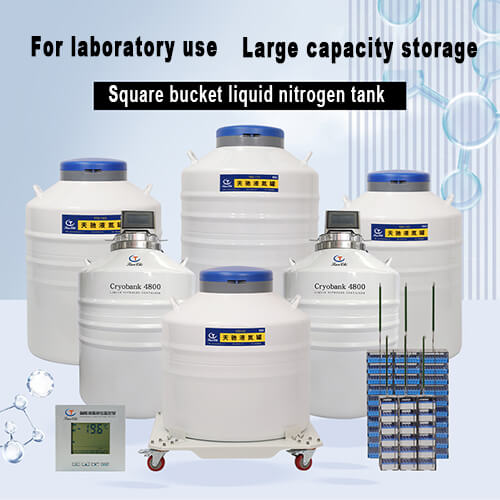

| 波斯尼亚和黑塞哥维那实验室液氮罐 KGSQ | 卖方: 河南天之道生物科技有限公司 | 在实验室,常用的液氮罐多是大容量,大口径,且有重量。若想转移,徒手搬运,难度系数高,还存在一定的危险性。而且还不能保证在转移的过程中会不会发生磕碰或意外。如果在转移中出现问题,那就得不偿失了。 ... | |

| 坦桑尼亚精子细胞储存 KGSQ ln2 容器 | 卖方: Henan Tianzhidao Biological Technology Co., Ltd. | 在实验室,常用的液氮罐多是大容量,大口径,且有重量。若想转移,徒手搬运,难度系数高,还存在一定的危险性。而且还不能保证在转移的过程中会不会发生磕碰或意外。如果在转移中出现问题,那就得不偿失了。 ... | |

| Ebike Battery | 卖方: Shenzhen Worldpower Energy Storage Technology Co.,Ltd | Custom Ebike Lithium Battery Manufacturer Elevate your electric biking experience with Worldpowe... | |

| Battery Energy Storage Systems | 卖方: Shenzhen Worldpower Energy Storage Technology Co.,Ltd | Battery Energy Storage Systems (BESS) are cutting-edge technologies that store electrical energy ... | |

| ETH Ethereum Jasminer X4 BRICK ASIC Miner | 卖方: Shenzhen Dovina Electronic Co.,Ltd | Jasminer X4 Brick Review Jasminer x4 brick for salefrom Jasminer mining EtHash algorithm with a ... |