ISO 11607: A Primer on Packaging for Terminally Sterilized Medical Devices

For many medical devices, sterilization is the final step in the manufacturing process before they’re shipped and used by patients and providers all over the world.

However, the act of sterilization isn’t the last thing manufacturers need to be concerned about. For the device to be safe for users and patients alike, it has toremainsterile from the moment it exits the sterilization process up until the moment it’s used.

The device’s packaging will dictate whether it stays sterile through the shipping, handling, and storage process—until the moment it’s needed. And because packaging is so important to the safety and effectiveness of sterilized medical devices, the International Organization of Standardization (ISO) has created a standard to address the packaging requirements for terminally sterilized medical devices: ISO 11607.

In this article, we’ll review the basics of ISO 11607 and walk you through the key packaging requirements you need to understand and follow in order to achieve a terminally sterilized medical device:

What is ISO 11607?

To say that a medical device is “terminally sterilized” is to say that it has undergone a sterilization process while the product is already within its packaging, which includes a sterile barrier system. Asterile barrier systemis the minimum layer of protection, often placed within an outer layer of packaging, that ensures sterility.

The “packaging system” as a whole is a combination of the sterile barrier system and any protective packaging used to prevent damage to the sterile barrier system or the device. Terminally sterilized devices are sterilized using an agent that can penetrate their packaging system, such asethylene oxideorgamma radiation.

This type of sterilization differs from aseptic processing, where products or components are sterilized separately and are later put together in a sterile environment. ISO 11607 covers the packaging requirements—for the entire packaging system—for any terminally sterilized devices.

The ISO 11607 standard is broken up into two parts:

-

: The first part of the standard covers the requirements and methods for testing the sterile barrier systems and packaging systems that are required to keep terminally sterilized medical devices sterile until they reach the end user.

-

: The second part of this standard includes the requirements for the development and validation of processes manufacturers must follow to ensure the sterile barrier systems for their medical devices work as intended and keep devices sterilized until their use.

-

What are the main requirements for medical device packaging in ISO 11607?

There are a lot of requirements for packaging in ISO 11607. In fact, the word “shall” (which in this context, means youmustdo it) appears more than 115 times in the document. For the sake of brevity, I want to outline just a few of the most critical requirements within the standard you must understand and adhere to:

-

First, ISO 11607 requirements explicitly state thatpackaging must keep the device sterile until the moment of use. This means a user must be able to bring the device out of the packaging without contamination.

-

The requirements from ISO 11607 also specify thatpackaging must come with instructions on how to remove the device from the sterile barrier system in an aseptic manner.

-

Additionally, thepackaging itself must be resistant to the sterilization process. This is a reference to the fact that popular terminal sterilization processes like ethylene oxide or radiation have the ability to deform or degrade certain types of packaging. So, the sterile barrier system and any protective packaging outside it must be able to undergo the sterilization process without degradation, discoloration, or any other defects.

-

One requirement of ISO 11607 that sometimes goes overlooked isstability testing. The shelf-life of a sterilized device depends in large part upon its packaging, and medical devicemanufacturers must test and prove that their packaging will ensure sterility throughout the shelf-life they claim for their device. This may include accelerated aging of the packaging or tests of its ability to withstand different pressures, temperatures, humidity levels, or applications of physical force.

-

Lastly, ISO 11607 also addresses the expectation thatsampling must be used to validate the packaging process. It emphasises that the sampling must be decided upon using a statistically valid method.

What changed in ISO 11607-1:2019 from the previous version?

The most recent update to ISO 11607 occurred in 2019, and it included some significant revisions. These revisions were made in an attempt to harmonize the standard with theGeneral Safety and Performance Requirements(GSPR) in the new European Union Medical Device Regulation (EU MDR).

Some of the updates in the 2019 version of ISO 11607 include:

-

A usability evaluation requirement for aseptic presentation in a real-world situation

-

A requirement to include risk management in the packaging process

-

An annex regarding environmental considerations

-

A new section on design change and validation

While ISO 11607:2019 is still relatively new, anamendment to the standardis currently underway to develop a GSPR-harmonized version. The reason for this being the current standard’s direction to “consider” risk management is not detailed enough. So, a future, amended version will contain a generalrisk management processthat addresses this inadequacy.

Keep in mind, though, this new risk management process will not expand the scope of the standard. The requirements and validation process outlined in both Part 1 and Part 2 of ISO 11607:2019 will remain current.

-

在线联系供应商

Other supplier products

| 山东逸风医疗科技有限公司 | 逸风医疗是一家致力于生产和销售各类医疗设备、制药机械和水处理设备的高科技企业。拥有ISO13485、ISO9001、CE等多项认证。是国内唯一拥有“医用智能密封设备工程”、“技术研究中心”等密封设备设计和生产企业称号的公司。本公司开发的30多种型... | |

| 封口机强度测试仪 | ISO11607-2(成型、密封和装配过程的验证要求)要求执行包装设备的性能鉴定(PQ)并记录在案。在PQ过程中,必须在灭菌后提供证明,证明该过程处于受控状态,并产生最佳密封或封闭的无菌屏障系统。 按照EN 868-5的要求,通过热封强度试验进行验证。热封强度测试是验证密封过程的测试。通过测试... | |

| 20T/H 饮用纯净水净化系统 | RO反渗透系统 康辉反渗透水处理设备采用预处理装置(石英砂过滤器、 活性炭、软水器、保安过滤器)带RO反渗透系统多重过滤 和分离水离子技术,除盐率可达97%-99% 工作流程图: 原水泵→石英砂过滤器→活性炭过滤器→防垢加药系统→保安过滤器→... | |

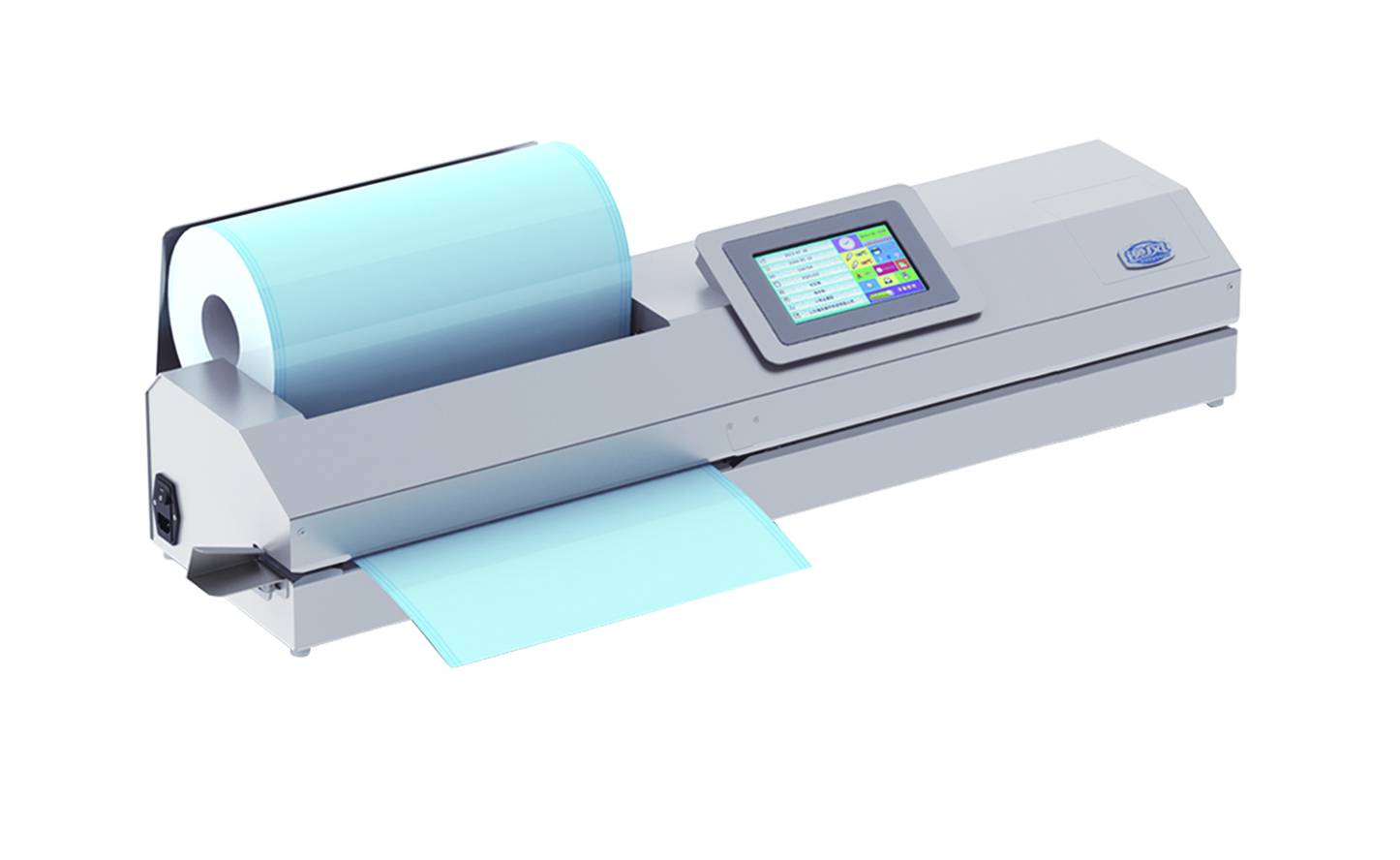

| 切割封口打印一体机 | 自动送料、切断、封口,Android操作系统触摸屏,只需按要求设置纸塑袋的长度和数量,启动程序,机器就会自动完成送料、切断、封口过程。 技术参数: ●控制系统:7英寸彩色液晶电容触摸屏 ●切割宽度:≤500mm(可同时切割几卷) ●切割长度:≥100毫米 ●切割速度:10&plu... | |

| 喷射洗涤枪 | 喷射洗涤枪(spay gun),型号 用铬电镀铝合金制成 专业机构,允许进行水压调节 专用抗滑有机硅材料自持手柄 装置快速、停机用的专业接水阀 8种不同填料用于我的洗涤和漂洗 固定在墙上,用于符合人体工程学地放置喷嘴 螺旋和水软管,最大延伸至255厘米 填料和固定件由AISI 304不锈钢... |