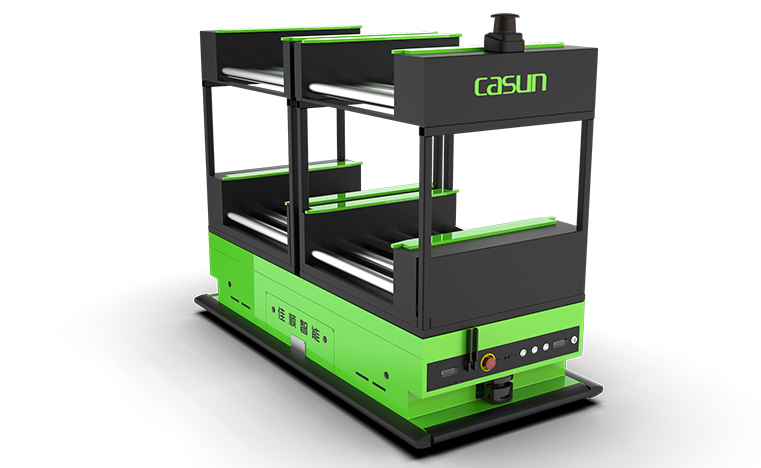

C3-41 Dual Layer-dual Conveyor Deck Load AGV

C3-41 converyor unit load carrier AGV is a single-layer three-station roller AGV. The roller platform and the production line or transmission line connection platform seamlessly and automatically dock for material transfer. The three groups of rollers are controlled separately, and the receiving and sending actions can be completed at the same time or separately. You can use magnetic navigation or QR code navigation according to different scenarios.

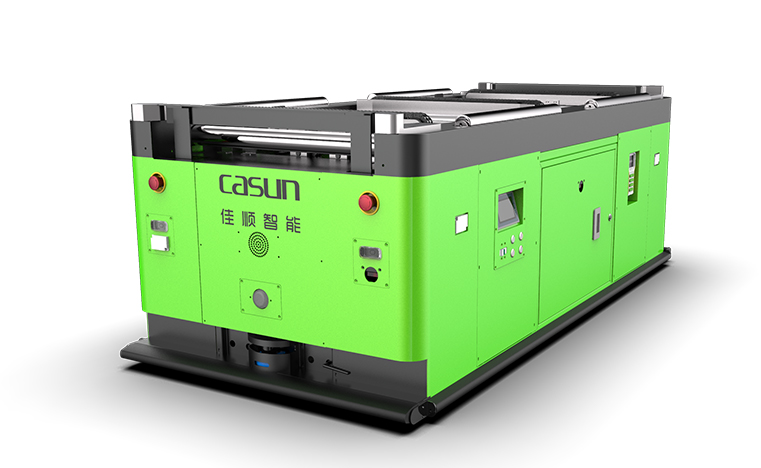

Parameters of C3-41 Double Layer Double Station Load Shifting AGV

|

Guidance |

Magnetic navigation/QR code navigation |

Stopping accuracy |

±10mm |

|

Dimensions |

L1800xW680xH1200(mm)(Docking height is 500/800mm) |

Driving method |

Dual-steering wheel |

|

Traveling direction |

Forward, backward, rotation and lateral |

Charging method |

Auto charger(Side /ground type) |

|

Load capacity |

500KG |

Battery |

Lithium battery |

|

Travel speed |

0~45m/min(Magnetic navigation),0~60m/min(QR code navigation) |

Communication |

WiFi/5G |

|

Turning radius |

900mm (Magnetic navigation) |

Safety alarm |

Sound and visual warning |

|

Conveyor deck number |

Four |

Safety detecting range |

≤3m(adjustable) |

|

Guidance accuracy |

±10mm |

Protections |

Front safety laser scanner+mechanical anti-collision bumper+emergency stop switch |

Core Advantages of C3-41 Double Layer Double Station Load Shifting AGV

01

Flexible operation

At the same time, it has the functions of 90-degree turning, 180-degree turning and lateral movement.

02

Multi-station, more efficient

The double-layer double-station roller supports four baskets of material transfer or empty-full exchange.

03

Get up and down the elevator

It can communicate and interact with ordinary elevators, and use elevators to complete up and down stairs.

04

Easy to use

Operate independently according to scheduling instructions, without manual intervention in the production process.

05

Fault self-check

It has perfect fault self-checking function, and has remote fault diagnosis and self-recovery function.

06

Linkage of multiple devices

Synchronous scheduling of multiple AGVs is suitable for complex material handling scenarios.

07

Automatic charging

When the battery is low, go to the charging station to automatically charge; it can achieve all-weather response and improve production efficiency.

08

Multiple security protection

Equipped with laser obstacle detection sensor, mechanical anti-collision device and sound, light and voice alarm to ensure safe operation.

Now the price of warehouse amrrobot is affordable, if you are interested, please leave us a message.

As one of agv manufacturing companies, we can offer kinds of agv carfor sale, anything you need, please contact us.

在线联系供应商

Other supplier products

| C7-11 Patrol AGV | C7-11 Inspection robot is used for outdoor routine inspection. It integrates autonomous navigation, autonomous inspection and autonomous AGV wirele... | |

| C3-42 Single Layer-four Conveyor Deck Load AGV | C3-42 is a single layer-four conveyor deck roller unit load carrier AGV, which can automatically dock with the production line or transmission line... | |

| C3-13 Single Conveyor Deck Load AGV | C3-13 single conveyor deck load AGV Trolley adopts an upper floating docking platform to achieve smooth docking with line-side equipment, which is ... | |

| C2-31 Omni-directional Latent Lifting AGV | C2-31 Omni-directional Latent Lifting AGV can move to the bottom of the material trolley, lift the material trolley and move to the destination. In... | |

| C5-Q2 Reach Forklift AGV | C5-Q2 is a forward-moving laser navigation forklift slam agv.The gable fork can be telescopic to avoid the interference between the machine and the... |