Ridge Cap Roll Forming Machine

ridge cap machineIntroduction

This machine is used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridge capping is placed along the peak of a roof to cover where the roof sheets meet. Roll-top ridge capping is a rolled product that is made to specific dimensions and cut to requested lengths. We manufacture both standard size ridge capping roll forming machines and also manufacture customized roll froming machines.

Features and Advantages ofRidge Capping Roll Forming Machine

Fullyautomatic continuous rollingforming machineforvarious sizes and specificationsridge capping undermass-production.Productionspeed: 15/20/30m/min.Certified with Multi-Patents; CECertified, EUROPEANquality standardMost of the hot & popular profiles models, we have ready roof tiles manufacturing machines in stock for prompt delivery.Finished Panels

Popular Ridge Capping Profile Drawings

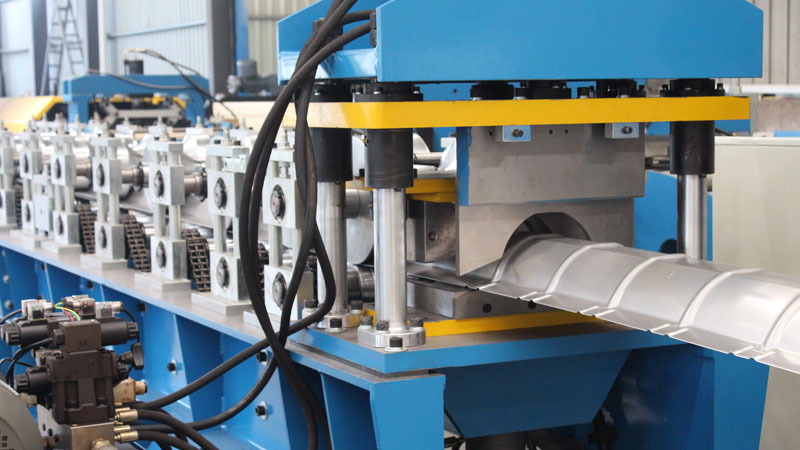

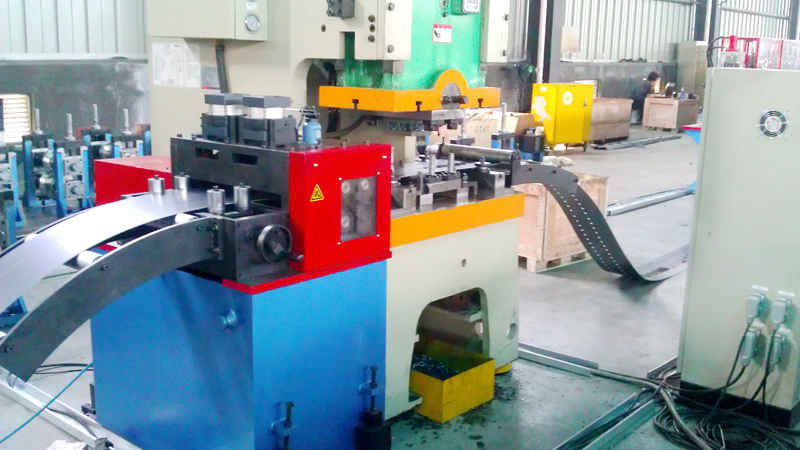

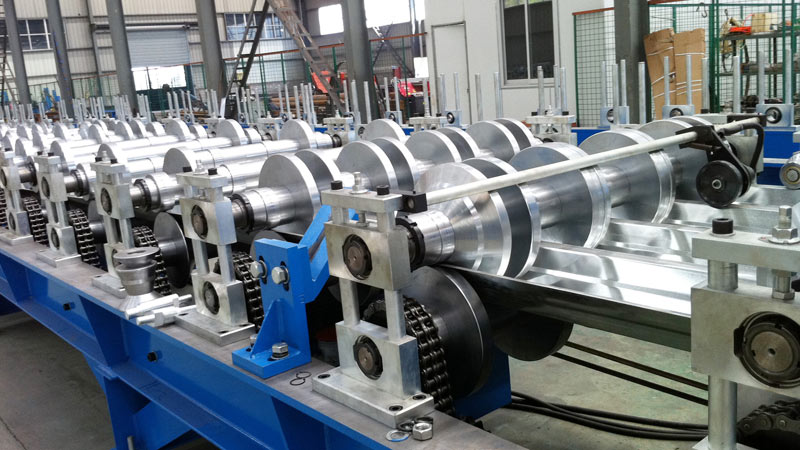

Working Flow ofRidge Capping Roll Forming Machine

Coil Charging Car(optional)Decoiler(passive/auto)Front Shear(optional)Feeding and Guiding TableFilming Covering (optional)Roll Forming SystemStep Punchingunit(as profile requests)Post-Cutting to length (Hydraulic/MotorOutput Manual Supporter/Stackmaster(optional)Ridge Capping Making Line Layout Drawing

Products ApplicationRoof ridge caps produced using this machinery are used for a variety of light steel structure construction and large building projects.

Suitable Raw Material

Material type: Color coated Steel, Aluminum sheet

Thickness: 0.3-0.6(mm)

Yield Strength: 230-300/350 (MPa) optional

Width: 385 (mm) as profile requests

Production line Components and Parameters

|

2t/3t/5t Motor/hydraulic motor/passive (optional) |

|

|

optional |

|

|

optional |

|

|

no need |

|

|

15/20/30 m/min |

|

|

optional |

|

|

Motor/hydraulic (optional) |

|

|

Manual supporter/ Automatic Stacker (optional) |

|

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

Power supply for decoiler /post-cutting system |

|

|

MITSUBISH/ SIEMENSE/AMS (optional or as requested ) |

Related Information

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator needed |

1 person |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 8t |

|

Dimension |

(L*W*H) about 20*2.5*2m |

|

LOADING SIZE |

Normally need 1x 40' container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

Hangzhou Roll Forming Technology Co., Ltd is a professional coil upender manufacturers, we provide steel coil upender, coil upender for sale, upender machine, roof ridge cap roll forming machine, metal roof ridge cap roll forming machine, roll forming equipment for saleand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Heavy Duty Shelf Column Roll Forming Machine | Our heavy-duty shelf column roll forming machine has been widely used in the production of city shelves, storage shelves, super heavy shelves, and ... | |

| Coil Cart | Introduction of coil transfer cart Thecoil transfer trolleyallows for quick coil change, but the most important feature is eliminating coil dama... | |

| High Speed Metal Deck Roll Former | Fully automatic, our high speed rollformer is designed with a Cassette-type platform and a quick-change machine base so as to better achieve multi-... | |

| Coil Embossing Machine | Cold rolling embossing machineis used to imprint designs and patterns onto metals such as steel, aluminum, and other alloys. The process of embossi... | |

| Roofing Tile/Glazed Tile Making Machine | Features and Advantages ofRoofing Tile/glazed tile making machine Roofing Tile & Glazed Tile Making Machine,is for continuously roll forming an... |