EPS Sandwich Panel Production Line

Main structure features ofEPS Sandwich PanelMachine

1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and high efficiency.

2) The EPS sandwich panel production line is welded by H-beam with shot blasting treatment on the surface, so the whole structure is simple and stable.

3) Consecutive laminating body transmission adopts worm and worm gear in order to control the producing speed steadily. The consecutive laminating body can cut to length with the advanced frequency control.

4) Three groups heating system to adapt the environmental temperature in different places.

5) Glue Providing system is driven individually. The horizontal compound, glue evenly, without any pollution.

6) Consecutive laminating body is long to guarantee the flatness of the sandwich panel.

7) The moving stroke of the cutting system is long to extend the life of the cutting tool.

Contact us forEPS sandwich panel machineprice! Or contact us for more information about othersandwich panel production machinery/line.

Main Technical Parameter of EPS Sandwich Panel Production Line

Specification ofSandwich panel produced by Jinggongsandwich panel making machine:

Length: Min cutting length is 2 m

Max cutting length is 15m

Width: (see profile drawing)

Thickness: (see profile drawing)

Raw material specification:

coil thickness: 0.4~0.6 mm (steel be flat without ups and downs, deformation and bending)

sheet yield stress: ≤235MPa

coil max width: 1200 mm (tolerance±2mm)

coil max weight: 4T

coil ID: Φ500 and Φ600 mm

coil OD: Φ1000 mm

EPS material: density is≥18㎏/m3, unstraight of each side ≤1㎜/m, curve ≤3㎜/m, surface be even, unevenness smaller than 1.5mm/m, EPS material single piece length more than 3m.

Material suitable shape: see profile drawing

Material suitable width: minimum shall be 1/2mm of the finished panel width.

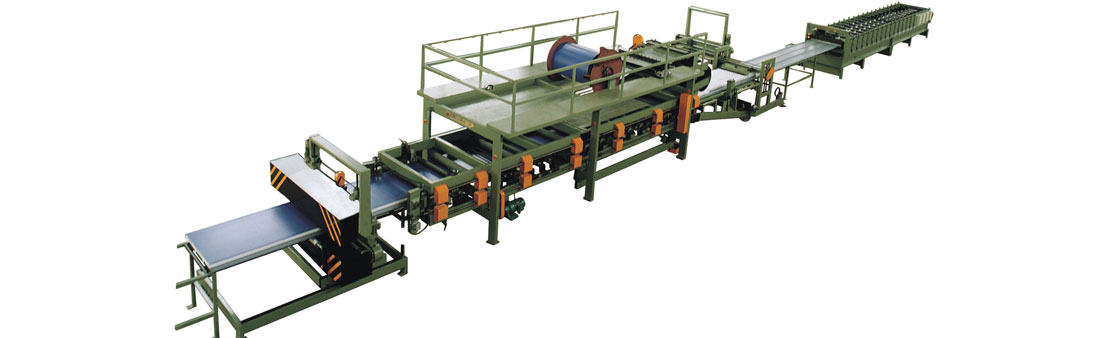

EPS panel production linespecification:

Work line speed: 1000-3000mm/min (frequency speed adjustment).Attention: depending on glue brand, temperature and proficiency of operators.

Machine length: about 40 m

Working height: 1050 mm(panel output height)

Laminating effective length: 7.5m

Control way: adopt industrial computer PLC

Total power: about 35 kw

Power: 380V/3phase/50 Hz

control voltage: 24 V/110 V/220 V

pneumatic: 0.7 Mpa (self-prepared by the factory)

best working temperature: around 25℃

Main Structure Components OfEPS Sandwich Panel Production Line

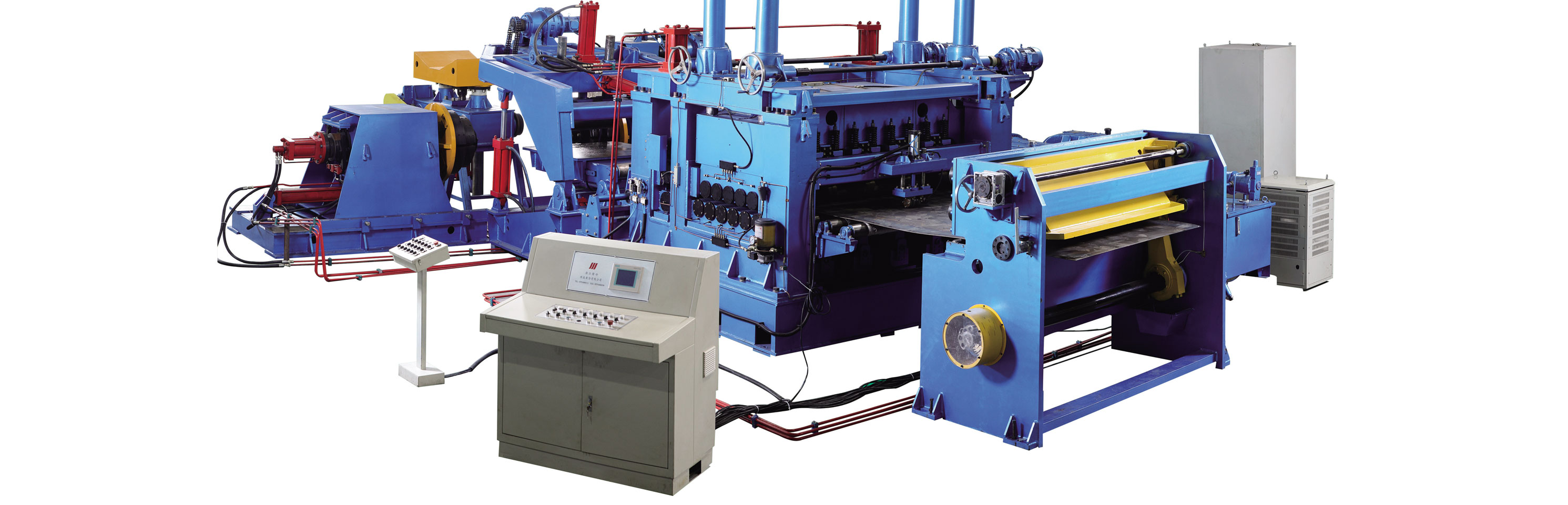

This EPS sandwich panel lineconsists of one roll forming machine and one laminating machine. It adopts international roll forming technology, laminating transmission technology, air-actuated and electric & hydraulic control technology. The whole EPS panel production line only needs 6 or 7 workers.

The whole sandwich panel machine lineconsists of two parts: roll forming part and laminator part.

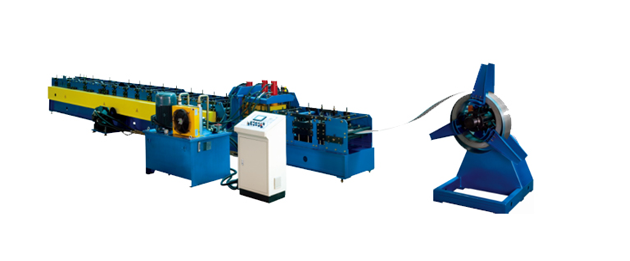

1) Roll forming part

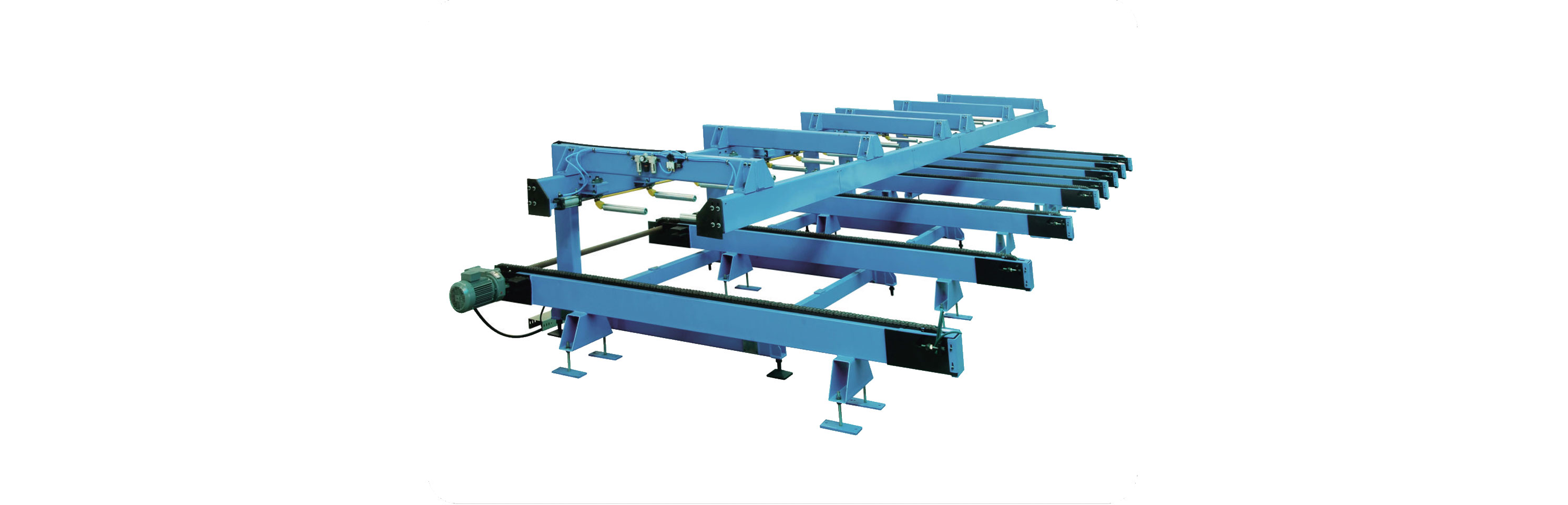

The roll forming machine consists of a hydraulic uncoiler, guiding system, filming system, flat sheet slitting system, roll forming system, panel support frame, assistant forming machine and so on.

2) Laminating body

This part consists of a guiding device, laminating body, cutting system, glue feeding system, support device and electric control system, etc.

Jinggong is a professionalsandwich manufacturing companythat has many years' experience and a lot of successful cases. We have got many positive reviews regarding thiseps panel machine. If you want to know more, please contact us now!

在线联系供应商

Other supplier products

| Auxiliary Equipment | Here is the different types auxiliary equipmentof our roll forming machine: curving punching forming machine, filming and cutting machine, slitter,... | |

| Cut To Length Line | Thischina cut to length machineis special equipment for uncoiling, leveling, cutting and stacking the steel sheet according to the requirement of t... | |

| The Core Equipment of Automated Three-dimentional Warehouse: Stacker Crane | Tracked roadway stacking crane, a special crane developed with the appearance of three-dimensional warehouses, referred to as stacker crane. It is ... | |

| C Z Purlin Roll Forming Machine | The c purlin machine china, also calledC Z purlin roll former /C Z purlin machine china. This type of C Z roll forming machine can change the profi... | |

| Sandwich Panel Line | Sandwich panel equipmentare widely applied in the protection and decoration of outside wall for tall building and first-class office building. Sand... |

Same products

| LEN503 Nebulizer | 卖方: Lepu Medical Technology(Beijing)Co.,Ltd | Cute pet caring Small atomized particles nebulizer machine for kids Adjustable atomizing cup H... | |

| SINOART Shanghai Co., Ltd. | 卖方: SINOART Shanghai Co., Ltd. | SINOART specializes in a series of easels, artist canvas, produced by Jinhua GOWIN and PAN’... | |

| FPQ2W-10/3T20 10kV Pin Insulators | 卖方: Guangdong Yufeng Industries Co.,Ltd | The crimping process of polymer pin type insulatorsshould pay attention to the crimping force, co... | |

| 洪都拉斯人工授精液氮罐KGSQ杜瓦瓶 | 卖方: 河南天之道生物科技有限公司 | 养殖行业中对畜牧液氮罐有着广泛使用,尤其在精子的冷冻与储存,远距离大规模配种方面,有着不可替代的作用。它伴随现代养殖技术出现,随着市场需求持续改良,容量和性能随着时间推移,前者越加丰富,后者更加... | |

| 布隆迪液氮杜瓦精液罐KGSQ | 卖方: Henan Tianzhidao Biological Technology Co., Ltd. | 养殖行业中对畜牧液氮罐有着广泛使用,尤其在精子的冷冻与储存,远距离大规模配种方面,有着不可替代的作用。它伴随现代养殖技术出现,随着市场需求持续改良,容量和性能随着时间推移,前者越加丰富,后者更加... |