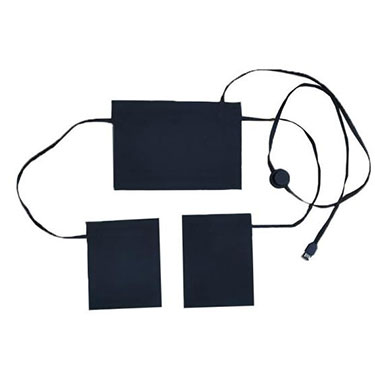

Battery Cold Plate

The main materials of battery cooling plates are aluminium alloy and stainless steel. Due to the requirements of low density and various forming processes, aluminium alloy can meet the lightweight requirements of the application end. At present, there are two process schemes for battery cold plate: integral casting and aluminium profile welding. And the technique of FSW is favored by more and more new energy automobile OEMs at home and abroad.

FSW welding has been widely used in the manufacture of EV battery cooling plateand EV battery tray FSW because of its non-melting, automation, intelligence, environment-friendly and integrated characteristics.

BATTERY COLD PLATE HIGHLIGHTS

Efficient Thermal Management

Battery cold plates efficiently dissipate heat generated during charging and discharging processes. This ensures that batteries remain at an optimal temperature, preventing overheating and thermal damage, which can extend the battery's lifespan.

Enhanced Battery Efficiency

By maintaining consistent temperatures, cooling plate batteryhelp batteries operate at their highest efficiency levels. This leads to improved energy conversion and longer-lasting battery performance, critical for electric vehicles, renewable energy systems, and more.

Reduced Downtime

The prevention of thermal-related issues translates to reduced downtime and maintenance costs. Batteries are less likely to fail prematurely due to overheating, making EV battery cooling plate a cost-effective investment in the long run.

Customizable Design

Battery cold plates are available in various shapes and sizes, allowing for easy integration into different battery pack configurations. They can be tailored to specific applications, ensuring an efficient cooling solution for any battery setup.

Environmentally Friendly

Maintaining optimal battery temperatures not only improves performance but also helps reduce the environmental impact. Batteries with effective thermal management systems are less likely to degrade quickly, reducing the need for frequent replacements and associated waste.

Wide Range of Applications

Battery cold plates are used in diverse industries, from electric vehicles and renewable energy storage to telecommunications and aerospace. Their versatility makes them a valuable asset in many sectors.

WHY CHOOSE CHEEVEN EV BATTERY COOLING PLATE?

Customization Options

Cheeven offers a range of customizable options for our battery cooling plates. Whether you have specific size requirements, need compatibility with certain coolants, or have unique design considerations, Cheeven can tailor our products to meet your needs.

Compatibility and Versatility

Cheeven's EV battery cooling plates are compatible with a wide range of battery chemistries, making them suitable for various EV models and applications. They are versatile and can adapt to different battery pack configurations.

Proven Reliability

Cheeven has a track record of providing reliable thermal management solutions to the electric vehicle industry. Our products are known for their durability and consistent performance in demanding conditions.

Safety Assurance

Maintaining batteries at the right temperature is crucial for safety. Cheeven's cooling plates for battery help prevent thermal runaway, reducing the risk of battery-related incidents and ensuring the safety of your EV.

Energy Efficiency

Efficient cooling means your battery operates more efficiently, which translates to improved energy conversion and potentially longer driving ranges for your electric vehicle.

Cost-Effective Solution

While investing in high-quality battery cold plates may have an initial cost, the long-term benefits in terms of extended battery life and reduced maintenance expenses make Cheeven's products a cost-effective choice.

If you are looking for a reliable die casting factory, don't hesitate to contact us!

在线联系供应商

Other supplier products

| High Damping Copper Alloy | Types of Copper Alloys and Their Uses Depending on the types of adhesives, types of copper alloys can be divided into rubber series, plastic ser... | |

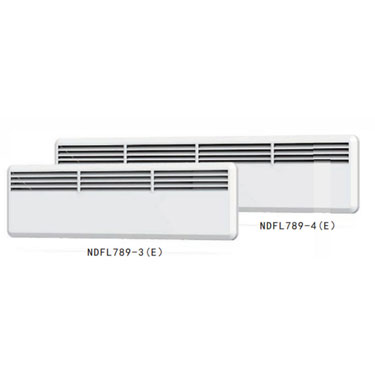

| Electric Heating Radiator | As top of electric radiator suppliers in China, Cheeven provides types of electric radiators. Efficient wall-mounted electric heaters can be used i... | |

| AUTOMOTIVE PARTS ALUMINUM DIE CASTING MARKET | Aluminum die casting is a process of casting aluminum alloy under high pressure. It is widely used in the automotive industry because of its advant... | |

| Aluminum Alloy Convection Heater | Heating elements can be selected: aluminium sheet or clay, power 600/900/1500/1800W, power switch, LCD digital screen control or remote control, te... | |

| High Purity Titanium Target | Based on high-purity titanium crystal raw materials, Cheeven can produce more than 99.99% high-purity titanium targets. The titanium sputtering tar... |

Same products

| Convection Panel Heater | 卖方: Ningbo Cheeven New Materials Technology Co., Ltd. | Cheeven has wall-mounted eco convection panel heaterwhich have functions such as power switches, ... | |

| Convection Heater | 卖方: Ningbo Cheeven New Materials Technology Co., Ltd. | Cheeven provides convection heaters for sale which have steel panels, like 400w convector heater,... | |

| Carbon Nanotubes Wall Paint | 卖方: Ningbo Cheeven New Materials Technology Co., Ltd. | Carbon nanotube black paint is a type of paint that contains carbon nanotubes, which are microsco... | |

| Carbon Nanotubes Products | 卖方: Ningbo Cheeven New Materials Technology Co., Ltd. | Carbon nanotubes are seamless, hollow tubes formed by graphene sheets formed by carbon atoms. Hav... | |

| Carbon Nanotubes Membrane | 卖方: Ningbo Cheeven New Materials Technology Co., Ltd. | The CNT carbon nanotubes membranewill undergo a high single-walled carbon nanotube preparation pr... |