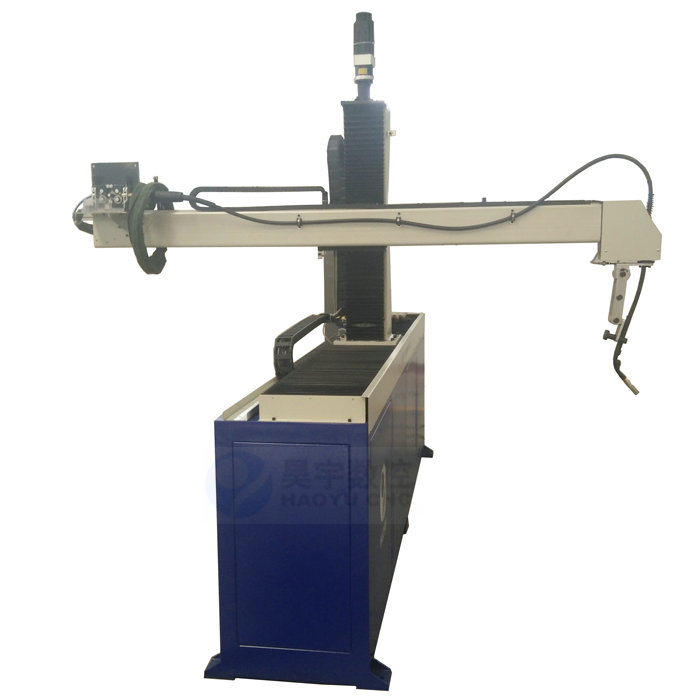

4 axis Automatic Welding Machine for Tipper Trailer

1. 4axis structure, and welding torch is installed in 4axis structure.

Workpiece is fixed in the mould, welding torch will rotate. Welding torch will be adjusted up and down, forward and backward, left and right

and angled movement.

2. The project is run by numerical control system. Welding type, specification and other parameters can be setup in one integrated control panel. There will be fault alarm and indication during welding process, such as stuck wire, blocked wire, etc.

3. Push-type wire feeder works stably. Machine is with high welding voltage and slow wire feeding performance, which guarantees reliable arc igniting. Machine is also with low welding voltage and low welding current for filling crater.

4. Machine is driven by AC servo motor. Servo motor reducer will guarantee smooth running during process of welding.

Other supplier products

|

|

4 axis automatic welding machine for cable ladder |

Special welding solution for cable ladder

The machine is used for welding relatively complex seams. It has the features of accurate positioning,... |

|

|

TIG Longitudinal Automatic Welding Machine |

Machine can weld steel, stainless steel, and red Cu Weld longitudinal seam on cylinder/tank. Welding process will be continual and steady. TIG ... |

|

|

Automatic Welding Machine for Tank |

Welding torch will weld double circular seams Melting thickness and width will be able to reach welding requirement. With uniform and smooth weld... |

|

|

4 axis welding machine |

4 axes robot Application Welding workpiece: Component name: Wheeler swing arm Product size: min 100mm -max 600mm MIG welding Machine can work conti... |

|

|

4 axes robot |

4 axes robot Application Welding workpiece: Component name: Wheeler swing arm Product size: min 100mm -max 600mm MIG welding Machine can work conti... |

供应产品

Same products