MX602K-7C CNC Busbar Punching Cutting machine,CNC Busbar Punching-shearing Machine

MX602K-7C CNC Busbar Punching Cutting machine,CNC Busbar Punching-shearing Machine

CNC Busbar Punching-shearing Machine is high-efficiency, high-precision busbar processing special equipment controlled by computers.

1.The machine is used in the process of punching, grooving, cutting filleted corner, shearing, embossing of busbar work pieces.

2.This machine uses Ball screw of high precision and linear guide rail, and adopts All the components of famous brand, which ensures that the machine is stable and reliable.

3.This machine may clamp long busbar at one times, it do not need manual intervention, the processing workpieces are fulfilled by automatically rechanging of pliers.

4.The User may select the mode of5punching 1 shearing1embossing and the mode of 7 punching 1 shearing of orthostichous Mould base (The User Also may add the function of embossing according to the requirement. ) to implement the technique of shearing off ,punching round hole, round hole for aluminum and copper busbars.

Shearing knife tool is the cutting of flat edge for one knife, Cutting mouth is neat and no burr, no waste materials, (Patent No.: ZL.human-computer interface, the operation is very simple, feedback real-time running state

5Hole distance accuracy≤±0.1mm the location accuracy of feeding material≤±0.1mm

6Adopting tridimensional turntable of nodular cast iron material for the mold frame, good abrasive resistance ensures concentricity of moulds for above and under punching hole during long use procedure.

7. Adopting 3mm thick steel plates to weld for hydraulic oil tank and having Phosphating process. , so that hydraulic oil can not deteriorate for long time.

8. There is CAD/CAM program software with the machine, G code will be generated directly according to the CAD drawing by the software

2.Parameter:

Model MX602K-7C

Max punching/shearing force: 60ton

Overall Dimensions (Length×Width×Height) 10500mm×2750mm×1800mm

Work Station Dimension

(mm) Feeding station : 2500mm×500mm.

Out station : 2500mm×500mm

Machine Weight 6700kg

Max metal Plate Dimension 6000× 200×16mm

Max Processing Thichness * Max Processing width 16×200mm

Max Punching diameter Φ4.3~35mm

Max numbers of installing mould : shearing moulds : 1

Punching moulds: 7

Parameter contrast Max Stroke of X-axis:2000mm

X-axis Accuracy Error:0.10/500mm(Accumulation) Max Stroke of Y-axis:960mm

Y-axis Accuracy Error:0.10/500mm(Accumulation) Max Stroke of Z-axis:310mm

T-axis Transmission length:4100mm

Stroke of beat cylinder:50mm

number of Control axles 3

3.The main accessories:

1.Main Motor: ABB

2.Hydraulic element: REXROTH

3. Guide screw: HIWIN

4.Servo motor: Panasonic

5. Programmable controller: SIEMENS S1200

6. Touch Screen/HMI: Grantech

在线联系供应商

Other supplier products

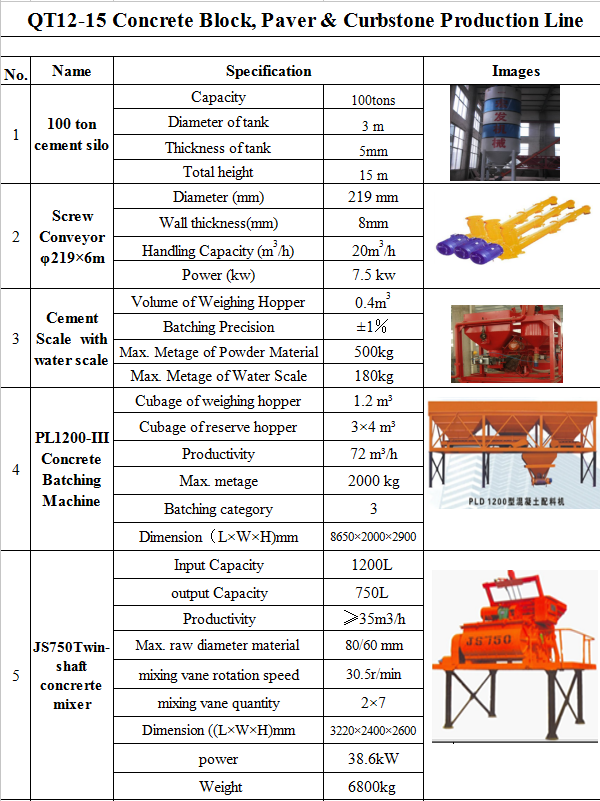

| QT12-15 Concrete Brick Paver & Curbstone Production Line/equipment/making machine | QT12-15 Concrete Brick Paver & Curbstone Production Line/equipment/making machine Concrete brick Concrete Brick Production Line Paver & Cur... | |

| RA-DZ101 Horizontal combination drilling machine | RA-DZ101 Horizontal combination drilling machine Henan Beshine International Limited located in Luoyang, an ancient capital of China, was invested ... | |

| Cable/wire stripping machine/multi-function wire stripping machines | Cable/wire stripping machine/multi-function wire stripping machines Applicable Scope Φ1mm~40mm Name New multi-function wire stripping machines ... | |

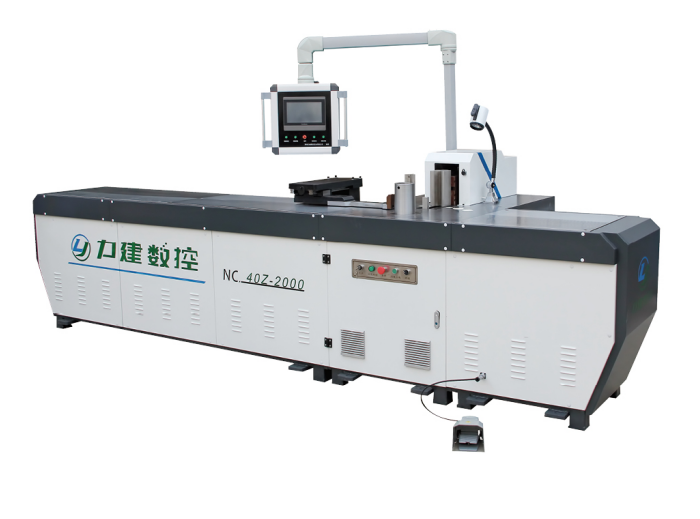

| NC.40Z-2000 high efficiency, high automation, high precision CNC Busbar Bender | NC.40Z-2000 high efficiency, high automation, high precision CNC Busbar Bender 1. Brief Introduction: NC.40Z-2000 CNC busbar bender is one process... | |

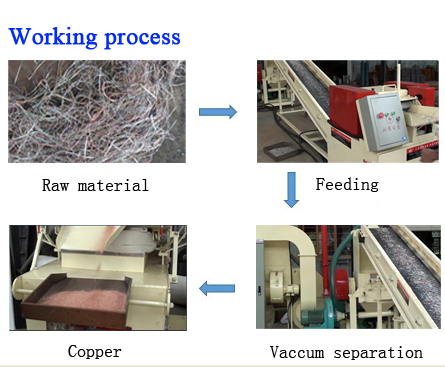

| low cost/economy copper/cable Recycling Machine | low cost/economy copper/cable Recycling Machine 600kg/h Copper Recycling Machine 1.Introduction Waste wire or cable gets crushed by two step crushe... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |