Screw Element

All component materials are supplied by domestic first-line brands or European professional materials suppliers of twin-screw plastics machines. And check the twin screw extruder screw elements and metallography to ensure that the raw materials are safe and nothing wrong.

100% internal spline is checked with a spline plug gauge to ensure the interchangeability of components.

All of our twin screw extruder elements are finished by CNC grinding after heat treatment. The surface roughness of this series is less than Ra0.8, which completely eliminates the influence of heat treatment deformation on the quality of components.

Powder high-speed steel is processed by the European HIP process and treated strictly according to the heat treatment process each other, the wear resistance and corrosion resistance of our twin screw extruder elements are the same as those of foreign first-line brands.

As a professional technical team of twin screw extruder screw elements, KEYA can not only provide timely and accurate twin screw extruder screw elements sample surveying and mapping design, but also provide technical services in twin screw element assembly.Buy from extruder screw manufacturer.

Whether domestic or foreign first-line brand mainframe, the company has detailed technical information and special fixture, which can provide spare parts service quickly; common components are fully stocked and shipped on the same day; new twin screw extruder screw elements are delivered within 45 days;

Perfect modern management system to ensure that customers receive 100% qualified twin screw extruder screw elements, while the quality of each twin screw element is traceable.

KEYA has different twin screw extruder elementsfor sale. Our high-quality products can surely meet your needs. If you're interested in our extruder screw elements, welcome to consult.

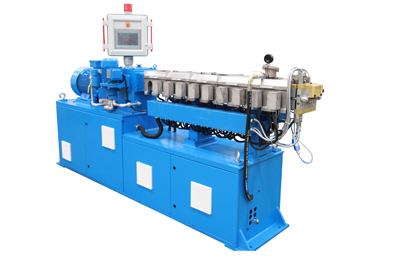

Buy from plastic extrusion machine manufacturers.

在线联系供应商

Other supplier products

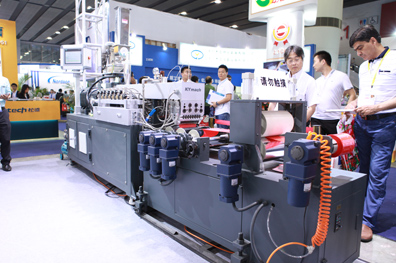

| HK Extruder for Small Batch Production | HK36 and HK53 small plastic twin-screw extruders are very competitive equipment models for small batch production scale, especially for the Color M... | |

| Biodegradation Recycled Plastic Extruder Machine | Biodegradable plastics refer to a kind of plastic that is degraded by natural microorganisms such as bacteria, fungi, and algae. The ideal biodegra... | |

| KY-Lab Twin Screw Extruder | aboratory extruder for sale / twin screw extruder for sale / lab extruder for sale Overview of KY-Lab Twin Screw Extruder Since its establishment... | |

| SK Series Co Rotating Twin Screw Extruder | Founded in 1993, Nanjing KY Chemical Machinery Co., Ltd. is currently one of the largest parallel co-rotating twin screw extrusion machinesuppliers... | |

| HK Large Extruder Production System | KY also offers a larger-scale HK twin screw extruder, with the commonly used screw diameters ranging from 110 mm to 165 mm (HK110-165) available fo... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |