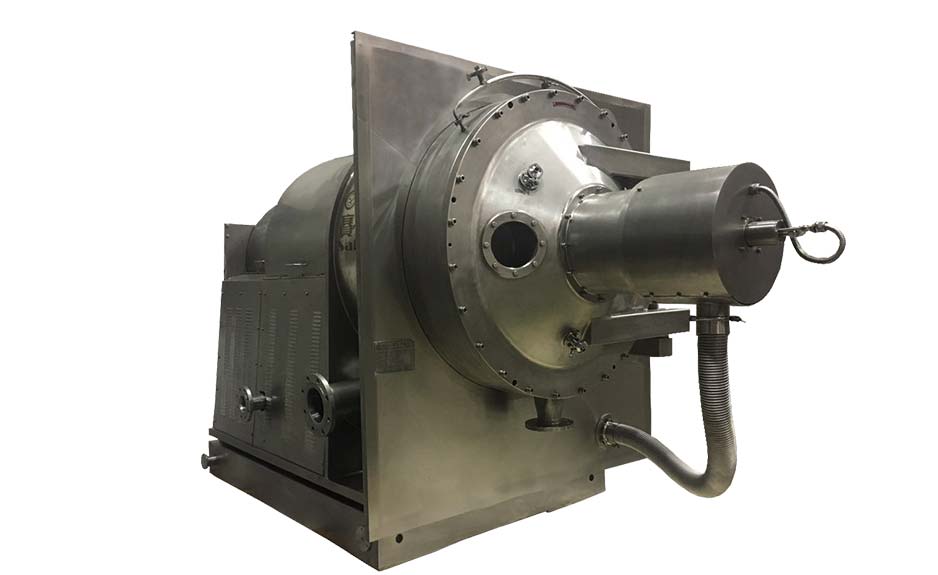

FSD CENTRIFUGAL DRYER

This industrial centrifugal dryerintegrates separating, drying, sterilization, with a perfect seal system, absolute security and is particularly suitable on high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in a sterile environment, and products sensitive to oxygen. As one of the best centrifugal dryer manufacturers, we make products with first-class quality. If you are interested in them, please fill out the form below to contact us. We will negotiate with you at a competitive centrifugal dryer machineprice.

FSD CENTRIFUGAL DRYER MACHINE WORKING PROCESS

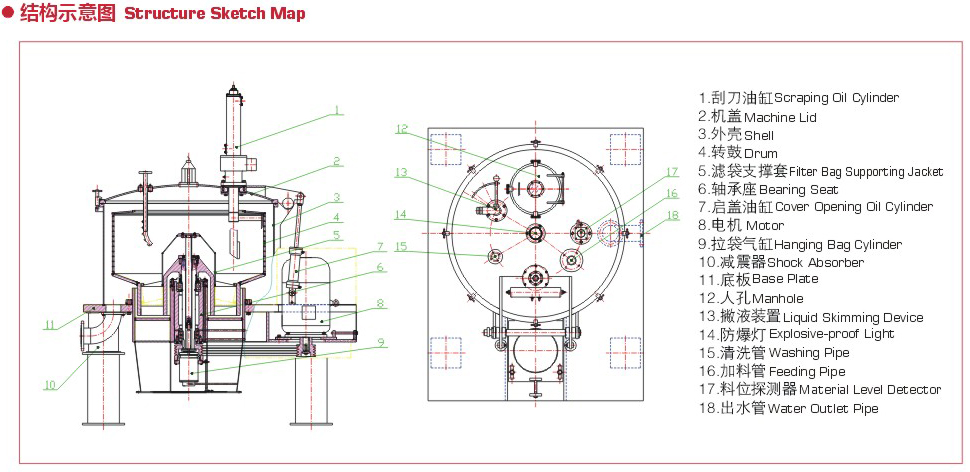

The suspension will enter into the rotating drum through the feeding pipe and the whole procedure will be monitored. The suspension will form a filter cake on the filter cloth and the mother liquid will be drained through the filter cloth. As the horizontal centrifuge machine, the filter cake will have an even structure. Usually, the filter cake will be washed after feeding. Under high speed centrifugal separation, mother liquid and washing liquid will be drained and the speed can be adjusted according to the material. After drying, the reduction of the speed will cause the collapse of the filter cake and form particles. The residual materials on the filter cloth can be removed by blowing from the nozzle. After all these, solid will be discharged.

FSD DRYING CENTRIFUGE FEATURES

Multifunction

Enclosed and whole sealing process space

Full automatic and high effective CIP system

High effective back flush drying

Components adopt standard module which is convenient for upgrade

Vacuum drying

Flexible process control

Sampling from whole sealing process space

Inspect process area

Full process inspection of material temperature

Saideli, as an excellent industrial centrifuge machine factory, offers a wide range of industrial centrifuge separatorfor you to choose from.

在线联系供应商

Other supplier products

| Industrial Centrifuge Separator Working Principle | INDUSTRIAL CENTRIFUGE SEPARATOR WORKING PRINCIPLE The industrial centrifuge working principleis fed tangentially to the cylindrical top of the cen... | |

| GKH AUTOMATIC SIPHON HORIZONTAL SCRAPER CENTRIFUGE | This screen centrifuge is controlled by PLC and regulates the speed by frequency convertor. The braking system of continuous centrifuge applies dyn... | |

| HR PISTONS PUSHING CENTRIFUGE | HR PISTONS PUSHING CENTRIFUGE As a good and professional pusher centrifuge manufacturer, Saidelihas been making high quality pusher centrifuge par... | |

| LB PLATFORM HERMETICAL TOP DISCHARGE CENTRIFUGE | The revolving speed of feeding, cleaning, and solid-liquid separating can all be adjusted in a certain speed range(from 0 to the rated revolving sp... | |

| HR Pistons Pushing Centrifuge | When the drum runs at a full speed driven by the main motor and transmission belt, the suspension of HR pistons pusher centrifugewill be led to the... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |