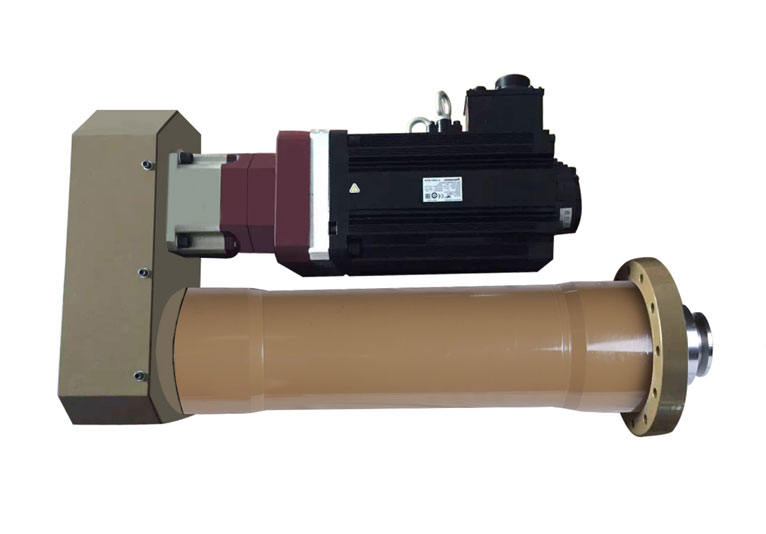

SPLIT-TYPE REDUCING MACHINE

The split type reducing machineis developed on the basis of TY801 standard reducing machine, which is specially designed for automatic assembly line. It has the advantages of high automation, high detection accuracy, stable product size after reducing, compact structure, complete functions, beautiful appearance, low power consumption and high production efficiency, which is suitable for the operation of automatic assembly line.

Operating Principle Of Split-Type Reducing Machine

The reducing machine is a kind of non-cutting processing equipment. It adopts the hydraulic technology to send round steel, screw thread steel, and other parts to be reduced into a special mold to be cold-reduced and formed. With the density of the reduced part is greatly improved, it will improve the compressive strength of the material without reducing the plasticity and impact toughness. The strength of the threaded connection and the rod is consistent, which solves the problem of reducing pressure resistance and impact toughness after the lathe skinning.

Product Use Of Split-Type Reducing Machine

TY801 reducing series is a kind of mechanical equipment specially developed for the manufacturers of automobile shock absorbers. It can be used for setting the outer diameter of automobile shock absorber bushing, trailing arm bushing, control arm bushing, suspension rubber sleeve, support arm bushing, and rubber sleeve.

Technological Process Of Split-Type Reducing Machine

Rough machining with a lathe first, with an allowance of 1mm;

Heat treatment to HRC60-62;

Finish machining on the lathe, with an allowance of 0.3mm;

Finish machining with an internal and external cylindrical grinder to the required size;

Laser printing the product number, and the arrangement number of 12 pieces;

Line-cut into 12 pieces, without cutting thoroughly, with an allowance of 0.5mm. when all cuts are finished, just knock to break;

Material: CR12 CR12MOV

Industry Pain Points Of Split-Type Reducing Machine

Temperature, voltage, and material rigidity will affect the reducing effect;

The equipment is too heavy to handle, and the oil temperature is poor in heat dissipation, unable to adapt to the production of the assembly line;

That the wear of equipment and abrasives affects the outer diameter will result in the high unqualified rate;

The complex process and the high consumables result in the high cost of the enterprise.

Product Advantages Of Split-Type Reducing Machine

Suitable for automatic assembly line operation with high work efficiency. This reducing series is a kind of reducing equipment for automatic assembly line operation specially developed by Tianyu Machinery with years of experience for the industry's pain points. It can greatly save working time, improve work efficiency and reduce unnecessary losses.

The outer diameter of the reducing diameter is adjustable and high-precision. And the product placement surface has a high-precision mechanical limit scale adjustment plate with a unit of 0.005mm, which makes the outer diameter adjustable. The wear of the equipment or mold will not affect the outer diameter of the reducing product.

It is easy to produce the mould at a low cost.

The reducing force is controlled accurately and is not affected by external forces. The TY801 reducing machine adopts a proportional overflow valve and a pressure sensor, together with a PLC programmable controller to form a closed-loop control system, which can realize that the reducing force won’t change with the effect of temperature, voltage, and material rigidity.

If you are looking for a reliable hydraulic press manufacturer, don't hesitate to contact us!

在线联系供应商

Other supplier products

| C FRAME PRESS MACHINE | Under the background of the increasing demand of universal hydraulic press market, our company has launched a high-precision and energy-saving hot ... | |

| CNC HYDRAULIC PRESS | TY502 is the equipment independently developed by Tianyu Machinery Equipment Co., Ltd. It can detect whether the interference between components is... | |

| Press Fit Machine | Our products mainly involve rubber vibration insulating devices, auto parts assembly facilities, motor assembly facilities, non-standard testing de... | |

| SERVO HYDRAULIC PRESS | TY203 series servo hydraulic press and CNC china hydraulic machineare independently developed and designed by Ningbo Tianyu Machinery Equipment Co.... | |

| TYD TURN-BACK SERIES SERVO ELECTRIC CYLINDER Free Quote | TYD series servo electric cylinders can work in a harsh environment for a long time without failure, and achieve high-intensity, high-speed, and hi... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |