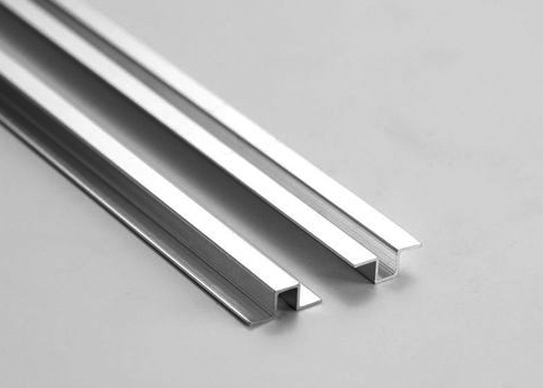

METAL FLANGING

Flanging refers to the stamping process of turning the edge or outer edge of the hole on the workpiece into an upright straight edge with a die. It is included in the forming process of stamping.

WHAT IS THE ADVANTAGE OF METAL FLANGING?

It can process precision stamping parts with complex shape and good rigidity.

Improve the production efficiency. Save dies for some deep drawing parts. Reduce the manufacturing cost.

It can replace the deep drawing work of a complex shape workpiece, so flanging is especially suitable for small batch trial production.

Flanging is usually applied at the edge of the stamping part, which can effectively save the material.

WHAT SHOULD BE CONCERNED IN METAL FLAGGING?

Flanging is a stamping method that turns the workpiece with holes punched in advance into vertical flange along the hole edge. The deformation of hole flanging is from the tensile deformation of the material along the tangential direction, and the closer to the edges, the greater the deformation and the flanged area of workpiece gets thinner. Due to that, the hole edge may be cracked if not dealt properly. In order to prevent the cracking, the flanging degree of the inner hole of the workpiece must not be too large. If the flanging height is large, we can process flanging several times instead.

In flanging, the deformation degree is expressed by cofficient "K", which is the ratio of the aperture before flanging to the aperture after flanging. Obviously, the larger the value of K, the smaller the degree of deformation. On contrary, the smaller the value of K, the greater the degree of deformation, and more likely the edge of the flanging hole will be broken. The minimum value of K occurs with the maximum deformation degree which can be achieved without cracking the hole edge.

In order to prevent edge cracking, K shall not be too small and shall be greater than the minimum value introduced above. Experience shows that the minimum value of K is not only related to the type and performance of the material, but also to the relative thickness of the blank, and the shape of the product.

If you need any kinds of metal work fabrication, please contact us, as a professional metalworking factory, Hongkun is willing to offer you high quality products.

在线联系供应商

Other supplier products

| CAR EXHAUST PIPE | Car exhaust pipeis installed between the engine exhaust branch pipe and the muffler, making the whole exhaust system flexible. In this way, it c... | |

| METALWORKING SERVICES & PRODUCTS IN AEROSPACE | Metal Welding Service& Products in Aerospace Sheet aerospace metal stampingparts occupy a very important position in aero-engines with their u... | |

| MOVER SEAT MOUNT | lawn mower seat bracketsis set into the seat of the mower in order to support the seat against the weight and pressure from the driver. What we are... | |

| METAL DEEP DRAWING | Metal deep drawing chinarefers to a kind of machining process in which a certain shape of flat blank obtained after blanking is stamped into variou... | |

| MOWER DECK WHEELS AND BRACKETS | Front forks operate as caster forks that absorb shocks, making drivers more comfortable and improving mower efficiency. It can extend the life of m... |

Same products

| Radio frequency signal generator | 卖方: 00000 | Radio frequency signal generator Radio frequency signal generator Overview Adopting DD... | |

| Commercial Vehicle Brake Pad WVA 29173 | 卖方: Qingdao Allmax Auto Parts Co., Ltd | ● ECE-R90 Certificate approved ● With warranty of 100000km-200000km ● OE supplier for 20 years ... | |

| Commercial Vehicle Brake Pad WVA 29125 | 卖方: Qingdao Allmax Auto Parts Co., Ltd | ● ECE-R90 Certificate approved ● With warranty of 100000km-200000km ● OE supplier for 20 years ... | |

| Custom Vehicle Brake Disc 9424212112 | 卖方: Qingdao Allmax Auto Parts Co., Ltd | Product Description Your is the silver piece that your brake pads push to bring the vehicle to... | |

| Commercial Vehicle Brake Disc 140272 | 卖方: Qingdao Allmax Auto Parts Co., Ltd | Product Description ECE-R90 Certificate approved With warranty of 1 year OE supplier No bub... |