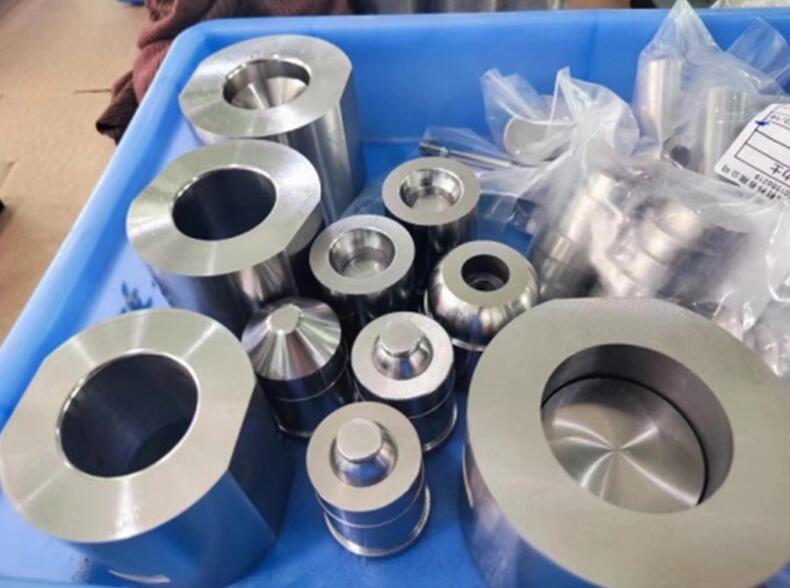

Carbide Mold Components

Carbide Components

We are very capable of customizing punches and dies to produce precision tungsten punches, bushings, ejectors, and die components from your CAD drawings. Our raw materials are imported from designated companies. Tungsten carbide has excellent hardness, wear resistance and corrosion and corrosion resistance. Ultra-hard tungsten carbide has a longer service life and can increase productivity through improved performance and reduced downtime.

Wear-resistant silicon carbide componentsare widely served by metal stamping production/manufacturing companies, custom metal fabrication, injection mold industry, metal mold/mold makers, tool and die makers and mold making industry.

What Has Cemented Carbide?

Cemented carbide is an alloy material made of hard compounds of refractory metals and bonded metals through a powder metallurgical process.

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, better strength and toughness, heat resistance, corrosion resistance, etc. Especially its high hardness and wear resistance, even at a temperature of 500 ℃ also remains basically unchanged, at 1000 ℃ still has a high hardness.

Cemented carbide is widely used as tooling materials, such as turning tools, milling tools, planning tools, drills, boring tools, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult to machine materials.

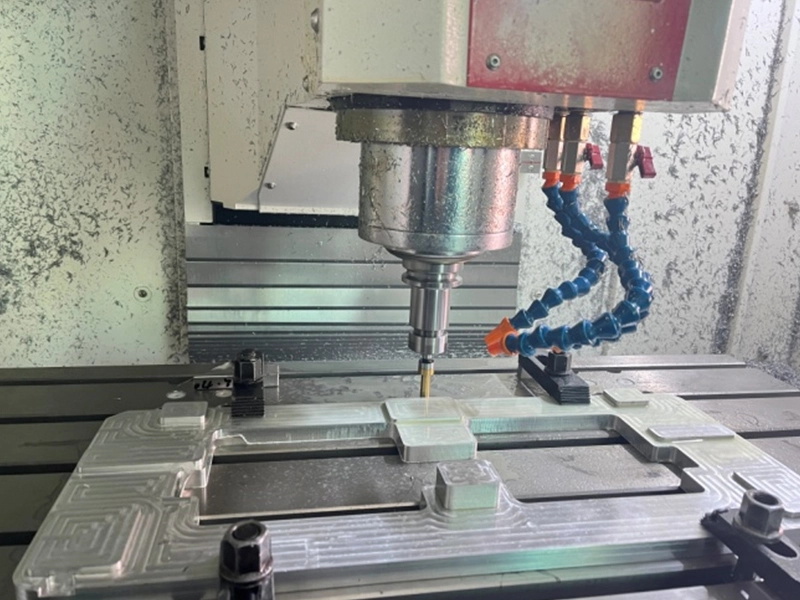

How Do You Make Hardware Mold Parts?

Precision etching is a process of creating patterns, shapes, and designs on a variety of materials, usually metals, using an etching process. As a part of precision quality machining, this process is often used in the manufacture of precision parts, such as integrated circuits, sensors, and other electronic components. In precision etching, the precision manufacturing companiescontrols the chemical reaction used to etch a desired pattern into the material, which is then filled with an etching fluid.

在线联系供应商

Other supplier products

| Brass Non-standard Parts | Brass Non-standard Parts Brass is an alloy of copper and zinc. Brass consisting of copper and zinc is called common brass, which has high strength... | |

| Rubber Prototyping Parts | Liquid silicone rubber (LSR) molding is a form of injection molding. The liquid silicone rubber is first injected into the mold, then the liquid is... | |

| PEEK Non-standard Parts | PEEKprecision machiningmaterial is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanica... | |

| Custom Precision Machined Parts | As the leading supplier of custom precision parts, we have 10 years of experience in custom fabrication services which include CNC machining servic... | |

| CNC Prototyping | CNC Prototyping CNC Milling and CNC Turning are excellent CNC machining prototyping options for parts that require prototypes to be evaluated in t... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |