Tungsten Rod

HSG METAL is a professional tungsten rod manufacturer and tungsten rod factoryin China. Pure tungsten rod is made of 99.95% tungsten powder. Its physical properties are as follows: density 19.3g/cm3, melting point (liquid) 3422°C, conductivity 30% IACS Min, hardness 69HRA Min. The forging and annealing process results can be obtained by test. It possesses special properties such as low thermal expansion with good thermal conductivity, adequate resistance to electrical resistance, and high elastic modulus. The products made from tungsten are widely used in various fields, such as support line, lead line, printer needle, all kinds of electrodes and quartz furnace, filament, high-speed tools, auto products, sputtering target material, heating device with special properties. It is generally made by powder metallurgy. Contact our tungsten rodmanufacturer for the latest price!

Specification of Tungsten Rod

|

iameter(mm) |

Black tungsten rod |

Polished tungsten rod |

Custom length tolerance(mm) |

||

|

Diameter tolerance (%) |

circular degree |

Diameter tolerance (%) |

circular degree |

||

|

±2 |

2 |

±0.03 |

L≤50±0.5 |

||

|

±2 |

2 |

±0.05 |

50<L≤100±1.0 |

||

|

±2 |

2 |

±0.08 |

100<L≤300±1.5 300<L≤500±2.0 |

||

|

±2 |

2 |

±0.15 |

±0.15 |

500<L≤1000±2.5 |

|

|

±2 |

2 |

±0.25 |

±0.25 |

1000<L≤2000±5 |

Application of Tungsten Rod

Tungsten rods possess special properties, such as low thermal expansion with good thermal conductivity, adequate resistance to electrical resistance, and high elastic modulus. Therefore, tungsten rods are widely used in various fields. Such as support line, lead line, printer needle, various electrodes and quartz furnace, filament, high speed tools, automotive automatic products, sputter target material.

Production Process of Tungsten Rod

Different average forging ratios and forging methods were used to draw the sintered pure tungsten bar, and the annealed tungsten bar was annealed under different annealing systems. The microstructure and physical and mechanical properties of the samples were analyzed by metallographic microscope, hardness tester and density tester. The results showed that:

When the total forging ratio is about 80%, the recrystallization of the tungsten rod forged at one end of one fire is basically completed after annealing at 1300℃ for 30 min, while the recrystallization of the tungsten rod forged at both ends of one fire is completed after annealing at 1350℃ for 60 min when the average forging ratio is larger. After annealing, the hardness of tungsten bars with the two forging processes will decrease, and the hardness of tungsten bars with the former process is less than that with the latter process before annealing and at the early stage of annealing, and this difference is no longer obvious with the completion of recovery recrystallization.

在线联系供应商

Other supplier products

| Tantalum Sheet | Tantalum sheet metalis tantalum tungsten alloy plate, tantalum platebright, no cracks, no peeling, no folding, no obvious oxidation, impurities pre... | |

| Niobium Wire | Niobium wire is cold worked from the ingots to the final diameter. The typical working process is forging, rolling, swaging, and drawing. Niobium... | |

| Tungtsen Powder | Tungsten powderis the main raw material for processing powder metallurgy tungsten products and tungsten alloys. Pure tungsten powder can be made in... | |

| Tungsten Crucible | Tungsten crucible is one of Tungsten metal products. It is mainly divided into sintering forming (applied to powder metallurgy technology), stampin... | |

| Ferro Molybdenum | Ferro molybdenum is a ferro alloycomposed of molybdenum and iron, generally containing 50-60% molybdenum, is used as an alloy additive for steelmak... |

Same products

| Cast iron pot with lid and 3 legs | 卖方: Hebei Chuihua Casting Co., Ltd | TheCast Iron Pot with Lid and 3 Legsis a classic South African-style bonfire pot designed for hea... | |

| Cast iron enamel Dutch baking pan with lid | 卖方: Hebei Chuihua Casting Co., Ltd | TheCast Iron Enamel Dutch Baking Pan with Lidis a versatile and stylish piece of cookware designe... | |

| A105 SW couplings | 卖方: Hebei Haihao Group Premium Pipeline Equipments Co., Ltd | A105 Carbon Steel Socket Weld (SW) Couplingsare essential components in numerous industrial appli... | |

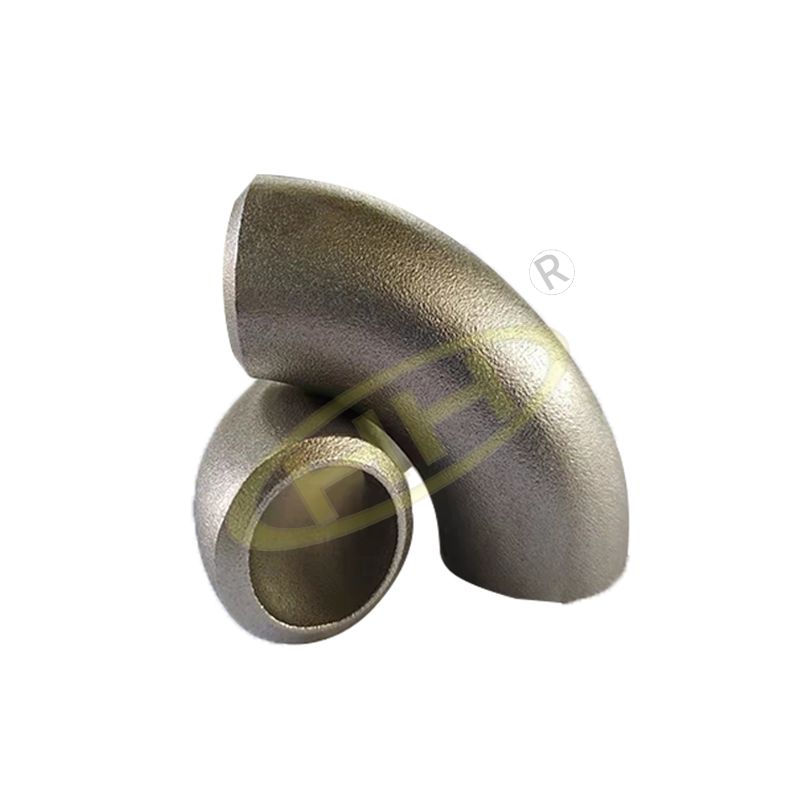

| A234 WPB Carbon Steel Butt Weld Elbow | 卖方: Hebei Haihao Group Premium Pipeline Equipments Co., Ltd | A234 WPB Carbon Steel Butt Weld Elbowis a high-quality piping component designed for use in high-... | |

| ASME A350 LF2 Welding Neck Flanges | 卖方: Hebei Haihao Group Premium Pipeline Equipments Co., Ltd | In industrial applications where safety, performance, and reliability are paramount, ASME A350 LF... |