Conveyor Roller Idler

Conveyor roller idlerAn idler roller conveyor uses paired rollers set at an acute angle to each other with the rollers being coplanar and skewed toward opposite sides of a perpendicular to a longitudinal axis of the conveyor. Roller pairs are preferably mounted in sub-frames that pivot about on an axis transverse to the conveyor’s longitudinal axis. This arrangement produces opposing transverse forces that are subtractive to result in negligible resultant transverse forces that are unlikely to make an object veer off course.The feature:1.High wear resistance, low friction, reduce the wear of the belt;2.Excellent self lubrication, no need of oil, not stuck in harsh conditions;3.Anti-static, anti combustion, aging resistance, resistance to chemical(acid, alkali and organic solvent)corrosion;4.Can withstand the repeated impact, vibration;5.Service temperature:From -40℃ to 90℃;6.Excellent mechanical properties, light weight, easy installation, no need to repair;7.Low noise(3~7DB),stable operation;8.Long service life.(3 to 5 times longer than metal rollers)Application:Idler roller conveyors are widely used to support the movement of objects to, through, or from workstations. In spite of extensive use for many different applications, idler roller conveyors can still cause serious problems. Many of these problems are caused by misalignment of conveyors with respect to workstations so that objects being moved over the rollers tend to move from their intended paths. These problems often occur from the way idler roller conveyors are manually set up relative to workstations. This is often done by eyeball positioning of a conveyor oriented in the intended direction of movement of an object.Slight angular misalignments can easily occur as idler roller conveyors are manually set up. They can also be misaligned even when they are fixed in place by system design. The effects of minor misalignments of infeed or outfeed conveyors can cause surprisingly large and clearly undesirable forces (forces perpendicular to the intended conveyor path) which urge an object to veer away from its intended direction of travel. We aim to minimize such forces and theharm they cause.SpecificationFlat rollerDiameterLengthNo89180、190、200、235、240、250、275、280、305、215、350、375、380、455、465、600、750、950、、200、240、250、305、315、360、375、380、455、465、525、530、600、700、750、790、800、950、1150、1400、1600204 205 305 306133305、375、380、455、465、525、530、600、670、700、750、790、800、900205、305、306159375、380、455、465、525、530、600、700、750、790、800、900、1000、1050、1100、1120、1150、1250、1400、1500、1600、1700、1800、2000、2200、2500、2800、3000、3150305 306 308193.72200、2500、2800、3000、3150、3350308 310217600、640、1050、1120、1600、1700、3150、3350308、310Impact rollerTapered self-aligning rollerComb cleaning rollerSpiral rollerThe friction self-aligning roller

Other supplier products

|

|

|

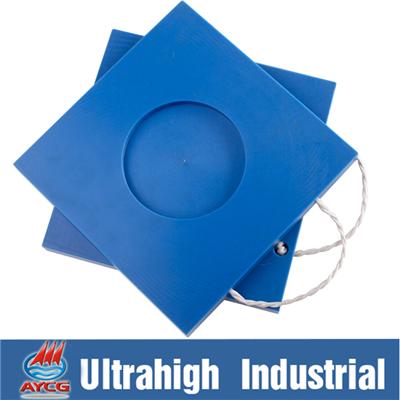

1.UHMW,UHMW’s molecular weight ranges from 3.1 million to 9.2 million for your choice2.Standard size:1x3m, 2x3m, 1.5x1.5mThickness: 3mm to 500mmWe ... |

|

|

|

NYLON / CAST NYLON (PA6/ PA6G)PulleyCast Nylon has been the ideal raw material for the manufacturing of varied range of Pulley Wheels due to its Du... |

|

|

|

1.UHMW,UHMW’s molecular weight ranges from 3.1 million to 9.2 million for your choice2.Standard size:1x3m, 2x3m, 1.5x1.5mThickness: 3mm to 500mmWe ... |

|

|

|

Nylon Bushes Features:Excellent Wear ResistanceExcellent Abrasion ResistanceLightweightVersatileEasy to Work WithVarious Grades AvailableBenefits o... |

|

|

|

V-belt pulleys (also called vee belt sheaves) are devices which transmit power between axles by the use of a v-belt, a mechanical linkage with a tr... |

供应产品

Same products