Peptide Synthesis Resins

Since spps Solid Phase Peptide Synthesiswas first proposed by Robert Bruce Merrifield, the method of synthetic peptides became more popular than liquid phase spps peptide synthesisbecause of high efficiency. This method could assemble a peptide chain rapidly through successive reactions of amino acid derivatives on an insoluble support.

The original peptide antibiotics are also biosynthesized and extracted from the culture of polymyxa or aeruginosa. Another synthetic method of peptides is chemical synthesis, which is divided into liquid phase chemical synthesis and solid phase chemical synthesis. The liquid phase method is mainly used for the synthesis of short peptides. The solid phase synthesis method can be used to prepare long-chain peptides, cyclic peptides, and complex. Peptide. The solid phase method is divided into a Boc method and an Fmoc method. It requires the solid phase synthesis of the carrier to achieve the growth of the peptide chain by means of stepwise amino acid condensation. The advantages of solid phase synthesis are ease of purification, shortening of the synthesis cycle, and ease of automation.

Solid phase peptide synthesis(SPPS) support consists of small, polymeric resin beads functionalized with reactive group such as amine or hydroxyl groups, which link to systhesis peptide chain step by step.

Advantages of solid phase peptide synthesisas follow:

Solid phase peptide synthesisresin(SPPS resin)is insoluble in all common solvents but swells well in most organic solvents. Better swelling degree is benefit for the reaction yields, but for short peptide resineasy to synthesis, lower swelling degree will be suitable and it will be good at saving solvent.

Solid phase synthesis Resinsare rich in variety, complete in specifications and stable in performance.

Sunresin is an innovation oriented high-tech ion exchange ltd. It is specialized in R&D, manufacturing and sales of adsorption and separation polymer resins, ion exchange equipmentand customized solutions including support services. As the first and the only A-share listed company in Chinese Ion Exchange and Adsorption Resin sun Industry, Sunresin manufactures about 50,000 cubic meters of ion exchange and adsorption resins annually, and supplies customers with tens of adsorption and separation equipment.

在线联系供应商

Other supplier products

| Rink Amide Resin | 4-(2', 4'-Dimethoxyphenyl-Fmoc-aminomethyl)-phenoxymethyl resin Rink amide resinis an excellent support for the Fmoc SPPS of peptide amides. This ... | |

| Typical Application Of Ion Exchange Resins | Separation Technique Based on Adsorbent for Extracting Plant Compounds Plant Extraction is a process to gather the trace bioactive compounds fro... | |

| Weak Acid Cation Exchange Resin (WAC) | SEPLITE ® Weak Acid Cation Exchange Resin acidic ion exchange resin? The words below would give a proper answer. The weak acid cation exchang... | |

| Cane Sugar Refining 21 | Ion Exchange Technique for Sugar Decolorization Resinand Deashing The usual process of cane sugar is extraction, purification, evaporation, concen... | |

| Wastewater Treatment&Reuse | Ion Exchange Solutions for Wastewater Treatment system Wastewater treatment is the process of converting wastewater into an effluent that can be d... |

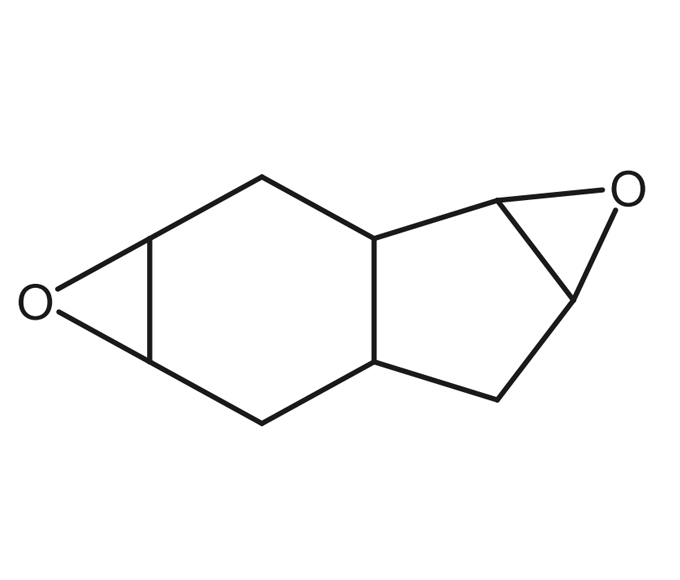

![TTA3150: Poly[(2-oxiranyl)-1,2-cyclohexanediol] -2-ethyl-2-(hydroxymethyl)-1,3-propanediol Ether Cas](/images/products/products_924544_4f9b8f86ea95820a3811548e7cdaa5ca.jpeg)