POLYMERIZATION REACTOR

POLYMERIZATION REACTOR

Polymers are high polymers consisting of smaller repeating monomer subsegments linked together to form chains. There are two main groups: naturally occurring polymers such as peptides and polysaccharides, which are important components of biological tissues, and synthetic polymers. Synthetic polymers are usually formed with water or other small molecules by adding monomer segments together through radical addition processes or by linking these segments together through condensation reactions.

There are many methods for polymerization, but the main methods are addition reaction and polycondensation reaction.

Methods Used For Addition Reactions Include

Bulk Polymerization - Reaction of a clean liquid monomer to form a polymer, such as PVC or LDPE.

Solution Polymerization - Dissolving the monomer and initiator in an appropriate solvent and then forming a polymer in solution. The polymer can be recovered by evaporation, or it can be left in the solution that will be used for coatings and adhesives. Polymers, such as polyacrylic acid, are usually made by solution polymerization.

Suspension Polymerization - The insoluble monomer is dispersed in an aqueous solution, where small polymer spheres form after the reaction is initiated. Small uniform size polystyrene beads are formed by suspension polymerization.

Emulsion Polymerization - In the presence of surfactant, insoluble monomers are dispersed in water as emulsions and form individual high molecular weight polymer microparticles (latex). Coatings and coatings as well as adhesives are widely used products formed by emulsion polymerization.

Methods Used for Condensation Reactions Include

Melt Polymerization - Mixing all reactants together in a pure way and raising the reaction temperature above the melting temperature of the resulting polymer. Polyester and polyamide fibers are formed by melting and condensation.

Solution Condensation - All reactants (monomers, catalysts) are mixed together in a non-reactive solvent. Synthetic elastomers are formed by condensation of solution.

Phase Condensation - Polymerization occurs and the resulting polymer resides at the interface of two immiscible phases. Polyaniline and polyimide are usually formed by phase-phase condensation.

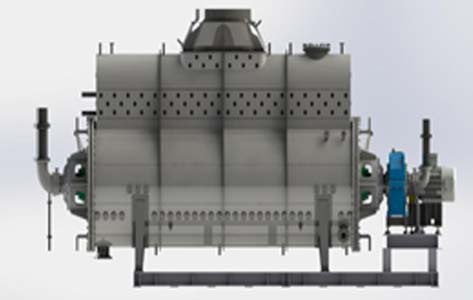

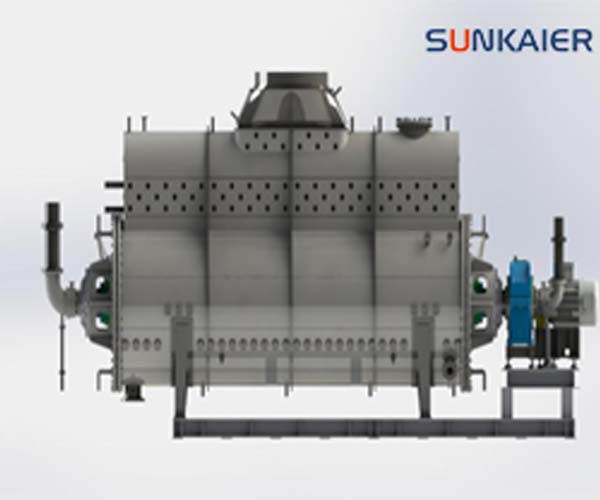

For the process production of polymers, SUNKAIER can provide comprehensive and accurate services in combination with specific polymerization reaction methods, from overall mixing, stirring to reaction. The main reactor types are as follows:

Tube Type: Mainly used in gas and liquid phase reaction. The composition of the reactants in the reactor varies continuously with the tube length. Reaction heat can be emanated from the casing or jacket outside the tube. Compared with other reactors, tubular reactors require the smallest reactor volume and the largest heat transfer surface per unit reactor volume to achieve the same production capacity and conversion rate.

Kettle Type: The most widely used in chemical production. Suitable for liquid phase, liquid - liquid phase, gas - liquid phase and liquid - solid phase reactions. Stirring device and heat transfer device are usually provided to ensure the flow, mixing and heat transfer of materials in the kettle. The kettle can be operated intermittently, continuously or semi-continuously. It can be operated in single tank or multi-tank series, with great adaptability and operation flexibility.

Tower Type: Long diameter is relatively large, according to the different structure of the tower has different characteristics.

Batch Reactor: The reactor in which raw material is added to a reactor at a time prior to a reaction until the reaction reaches a specified conversion rate to produce the reactant, usually with a stirrer. Advantages: large operation flexibility, mainly used for small batch production.

Continuous Operation Reactor: The continuous addition of reactants to the reactor and the continuous withdrawal of products to the reactor belong to the steady-state process, which can be used in kettle, tube and tower reactors. The advantages are: suitable for large-scale industrial production, strong production capacity, stable product quality and easy to realize automatic operation.

Semi-Continuous Operation Reactor: In advance, part of the reactants are added to the reactor once before the reaction, and the rest of the reactants are added continuously or broken continuously during the reaction, or some products are continuously removed from the reactor during the reaction, which belongs to the unsteady process. The advantages are: the reaction is not too fast, the temperature is easy to control, is conducive to improve the conversion rate of reversible reaction.

Sunkaier is Experienced in the Production of Polymer Materials Such As

Single Stage of High Monomer Yield

Mixing / Compounding

Treat Wet Powder

Devolatilization of Shear Sensitive Resin

Elastic Product

Polycondensation or Other Bulk Polymerization Reactions: such as PBAT, PLGA, PET, PMMA, Trans Neoprene, PGA, PLA, PCL, Bulk ABS, PVDF, etc.

Solvent Polymerization: All Kinds of Synthetic Rubber, TPE Elastomer, etc.

Solvent Removal of Polymer, Synthetic Rubber or Elastomer: such as Hydrogenated Nitrile Rubber, POE Elastomer, Various Styrene Butadiene Copolymers, Butyl Rubber, SBS/SEBS, Acrylate, etc.

Removal of Residual Monomers: such as PPC Resin, Silicone Rubber, etc.

Other industries include but are not limited to gum, bubble gum, toothpaste, plastics, rubber, silicone rubber, dyes, pigments, inks, food adhesive base, pharmaceutical agents, architectural coatings, carbon, fiber, high viscosity sealant, neutral glass adhesive, aluminum silver paste, silica gel, pulp, fiber, battery paste, dyes, silicone resin, cosmetics and other industries.

For more informationabout polymerization reactor design, please feel free to contact us!

As a professional chemical process equipment manufacturer, sunkaier has high-quality chemical industry equipmentfor sale. Welcome to contact us if needed.

在线联系供应商

Other supplier products

| FORCED CIRCULATION EVAPORATOR | Forced Circulation Evaporator Design The materials are evenly arranged in each evaporator tube through the liquid material distribution device on ... | |

| CHEMICAL SEPARATION EQUIPMENT | The liquid extraction equipment is mainly used for chemical reaction, material separation, heating and cooling, liquid extraction, gas absorption a... | |

| MAGNETIC AGITATOR SK1000 | Magnetic seal comprises of a sealed chamber (Shroud), which contains a rotating Inner Shaft, which is embedded with powerful Inner Magnets. This in... | |

| POLYMER PROCESSING EQUIPMENT | What is polymer technology SUNKAIER polymer technology can provide comprehensive and accurate services in combination with specific polymerization... | |

| INDUSTRIAL VACUUM DRYER | INDUSTRIAL VACUUM DRYER SUNKAIER vacuum disc dryer is an energy-saving drying equipment, which is equipped with a main shaft and blades. The wet m... |