Petroleum Coke and Ash Lime Crushing Equipment

1. Application Material: Petroleum Coke

2. Feed size: ≤200mm Moisture ≤5%

3. out size: 325mesh(D97), particle size can be adjusted.

4. Output: shot coke 3t/h-4t/h ; sponge coke 4t/h-5t/h

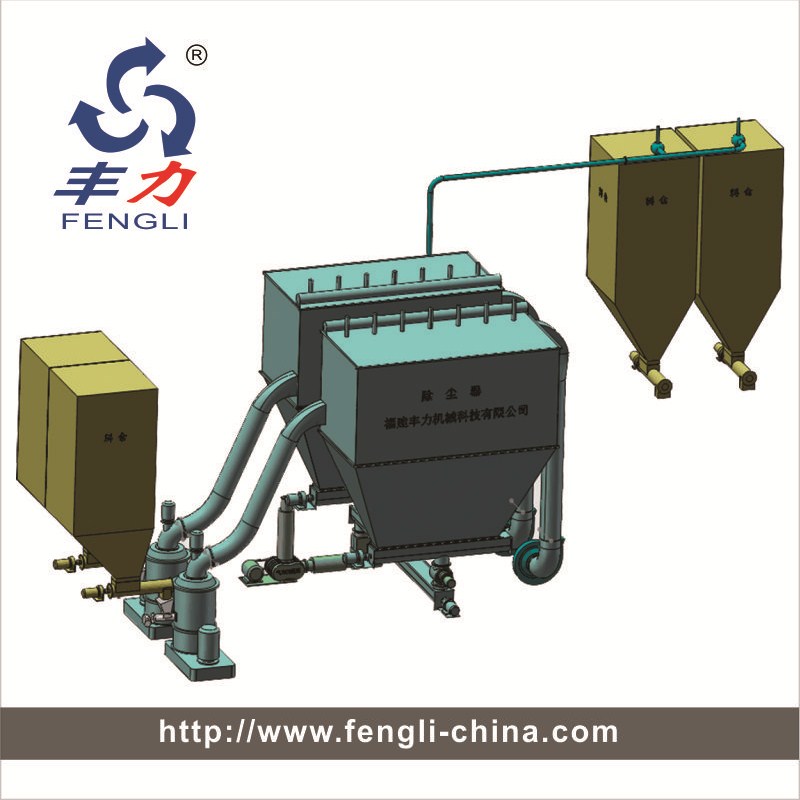

5. Supply completed grinding machine (including crusher, conveyor equipment and grinding machine)

FLM-1000 grinding machine is suitable for petroleum coke, including crusher, conveyor equipment (including auger and powder pneumatic conveying),grinding machine. Simple process flow diagram(detail information is on attachment)

FLM-1000 petroleum coke grinding mill is the use of violent impact hammer / Blade / rods and materials and other high-speed rotation of the rotary body, while at the impact of the gap between the hammer and the liner impact / abrasion scissors cut, to achieve ultra-fine grinding powder.

The model choose characteristics of petroleum coke , using the CFD fluid dynamics simulation software to calculate the most suitable flow field, pressure distribution to guide the design, improve the grinding efficiency, reduce energy consumption.

FLM-1000 grinding machine for petroleum coke feature:

1.Grinding machine is based on petroleum coke characteristics, using numerical simulation software to design the most suitable crushing and classifying flow field, to optimize main engineer system and turbo air classifier design, effective solution to the problem of adhesion, increased capacity and no large particle size appear;

2.The mill is good at small installed power, optimizing system structure, reducing energy consumption greatly, installed power lower than other similar models;

3.The mill is powerful blowing when running,also has a certain drying function on material; the device can dry material with 80-100 ℃ flue gas.

Raw water is 9%, the finished powder moisture ≤3%;

Raw water is 7%, the finished powder moisture ≤2.2%;

Raw water is 5%, the finished powder moisture ≤1.5%;

4.The mill choose unique design and a constant flow field of gas-solid concentration control technology, a uniform particle size, narrow distribution, no large particle size, and to ensure the stable operation of the system a long time

5.Grinding hammer and ring use cemented carbide materials which made through a special process, the alloy wearing spare parts use abrasion treatment, which increase the service life of wearing parts, service life is 3-4 times than other similar models ,and greatly reduces the contamination of iron impurities; (this method has been very good in application a number of units)

The mill choose unique protection disc design, effectively reduce the wear of the disc, greatly extending the life order.

1. Our design idea is market-oriented and its goal is to increase customers’ satisfaction. Design according to the customers’ special requires. Achieve the perfect combination of rational investment and lower cost.

2. According to related national standard strictly, we guarantee stable and reliable product quality with superb technique and technology.

3. Control the production and examination of the parts and the whole machine strictly.

4. The period of quality guarantee of the equipment is one year, but the whole machine is maintained for whole life. If we receive complaint from customers, we will respond immediately. And if necessary, we will send someone to the field at once.

5. When technical breakthrough and improvement happen, we will do the correction and upgrade for customers with cost price only if customers will.

6. Supply the blueprint of the product line and equipment details for free.

在线联系供应商

Other supplier products

| New Developed Superfine Powder Mill Scattered Depolymerization | Technical features Using the numerical simulation software to design a suitable crushing and split flow, optimize the grinding ma... | |

| Custom Make Electrophoretic Shell for DC Motor | 1.Material:Steel tube. 2.Standard:ASTMDINBSJISGB. 3.Surface finish:electrophoresis. 4.Weight: 0.5-5kg. Fujian Fengli Machinery Technology Co.,Ltd ... | |

| ACMX-935B Nano Powder Mill Scattered Depolymerization | TheACMX-935BserieswasupgradedtypefromACM/Bseries, whicharehighlyefficientsuper-finepunch-action mechanical micro grindingmachinescapableofperform... | |

| ACM Series Grinding Machine for Making AC Foaming Powder | Based on our ACM/A Series grinding machine, the ACM/B series grinders are part of our patented new generation innovative products (China Patent... | |

| OEM Custom make Iron Casting Elevator Traction Hub | 1.Material:different grades of gray iron, ductile iron. 2.Standard:ASTMDINBSJISGB. 3.Surface finish:shot blasting,painting,etc. 4.Weight: 5-500kg. ... |

Same products

| HM Pumex Grinding Machine | 卖方: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro 电动研磨笔 IC 抛光工具 | 卖方: 深圳维客修科技有限公司 | XZZ Z1 Pro 电动抛光笔,配备多种磨头,满足不同类型的手机主板 CPU IC 研磨和维修需求。2025 XINZHIZAO XZZ USB 充电式抛光研磨笔,适用于手机维修。 XZZ ... | |

| Scraper Grinding Machine | 卖方: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| IC抛光用小型电动研磨笔 | 卖方: PHONEFIX technology Co.,Ltd | 描述E288-02小型手持研磨机迷你主板CPU IC抛光笔雕刻工具。电动研磨笔适用于手机维修,IC CPU抛光,玉石玛瑙,核雕,木雕,研磨铝板,印刷电路板和环氧板以及手机液晶屏残留OCA胶去除。... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | 卖方: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |