Armstrong Gasketed Plate Heat Exchangers

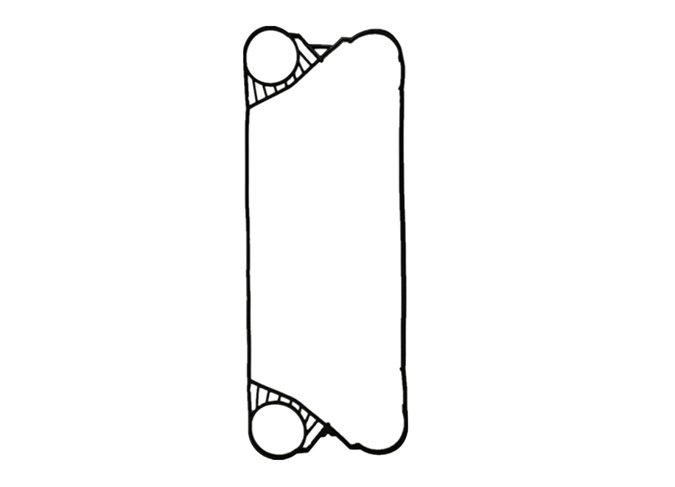

The armstrong plate and frame heat exchangers incorporate a series of uniquely corrugated metal plates arranged within a frame and secured by two pressure plates (one fixed and one adjustable). These plate designs by Armstrong are specifically engineered to maximize water-to-water heat transfer, resulting in improved performance, particularly in HVAC applications.

Features of Armstrong Gasketed Plate Heat Exchangers

01

High Heat Transfer Efficiency

Armstrong gasketed plate heat exchangers utilize specially designed corrugated plates that create turbulent flow patterns. This enhances the heat transfer efficiency by promoting optimal heat exchange between the fluids.

02

Wide Range of Material Options

Armstrong plate heat exchangerprovides a variety of plate and gasket material choices, including stainless steel, titanium, and various elastomers. This allows for compatibility with different fluids and resistance to corrosion, ensuring reliable operation.

03

Easy Maintenance and Cleaning

The gasketed plate design of Armstrong plate heat exchanger allows for easy disassembly and reassembly, simplifying maintenance, cleaning, and inspection. This reduces downtime and enhances operational efficiency.

As one of plate heat exchanger companies, we can offer sorts of related products for sale, if you have needs, please leave us a message.

在线联系供应商

Other supplier products

| Brazed Plate Heat Exchangers | Brazed plate heat exchangers are constructed with a series of thin, corrugated stainless steel plates. These plates are carefully stacked and braze... | |

| Tranter Heat Exchanger Plates | Tranter Heat Exchanger Plates Tranter heat exchanger plates are highly regarded for their industry-leading quality and performance. These plates a... | |

| GEA Heat Exchanger Plates | GEA heat exchanger plates exemplify excellence in design and engineering. With advanced technological innovations, GEA offers a wide range of plate... | |

| GEA Heat Exchanger Gaskets | GEA Heat Exchanger Gaskets GEA heat exchangers are commonly used in the beverage and beer industry, heating/cooling, yeast cooling, pasteurization... | |

| HISAKA Gasketed Plate Heat Exchangers | HISAKA heat exchangers can be provided in the shortest lead time 2-3 days, our stock level can meet any of your urgent projects. Features of HIS... |