JIANGYIN DINGBO TECHNOLOGY CO., LTD

联系方式

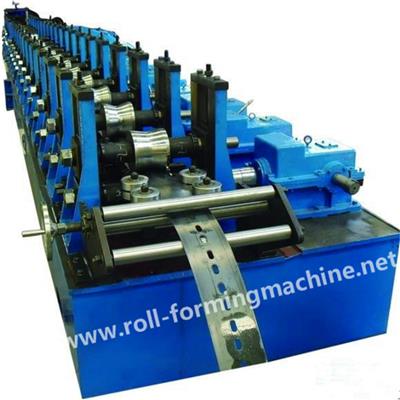

JIANGYIN DING BO TECHNOLOGY CO.,LTD is a manufacturer specialized in customizing all kinds of roll forming machines. With our advanced techniques and experienced staff,Website:, we can produce simple profiles as well as complex components with precision tolerances. Most of our main production staff have more than 10 years of experience, which ensure good machine quality and high values for our customers. Advantages of Our Roll Forming Machine: Roll formed parts can have a variety of shapes, angles and curves. Many materials are suitable for our custom roll forming machines,such as produce color steel roof sheets, C/U/Z/M/T/L steel purlins, metal floor deck, cable tray, fire damper, rack pillars ect . We design products that best meet specific needs. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to build successful business relationships with new clients around the world in the near future. Company Advantages: 1. Fast Delivery Time (25-40 days only) 2. Competitive Price (95% suppliers were defeated) 3. Good machine Quality ( Panasonic, Siemens product equipped with our machines) 4. 24h* 7 After-sales Service (Support Email, Skype, Whatsapp, video meeting ect.)

产品:

| Supermarket Shelves Roll Forming Machine | The profile drawing for supermarket shelves roll forming machineThe thickness of Material: 1.5-2.5mm Working flow of supermarket shelves roll form... | |

| Shelf Making Machine | The profile drawing of shelf making machineThe thickness of Material: 1.5-2.5mm Working flow: uncoiler—Leveling—Punching--roll forming--- hydraulic... | |

| Fire Damper Roll Forming Machine | The profile drawing of Fire Damper Roll Forming Machine The thickness of Material: 2.0-3.0mm Working flow: Uncoiler—Feeding—Leveling—Punching--r... | |

| Shelves Roll Forming Machine | The profile drawing of shelves roll forming machine The thickness of Material: 1.5-2.5mm Working flow: uncoiler—Leveling—Punching--roll forming---... | |

| L Purlin Roll Forming Machine | Working flow: Decoiler--feeding--punching--roll forming--cut to length--output table Equipment list: NO.ProductQuant.1Manual decoiler12Mai... | |

| Steel Rack Shelf Roll Forming Machine | The profile drawing for steel rack shelf roll forming machine The thickness of Material: 1.5-2.5mm Working flow: uncoiler—Leveling—Punching--roll... | |

| M Purlin Roll Forming Machine | The profile drawing of M Purlin Roll Forming Machine The thickness of Material: 2.0-3.0mm Working flow: Uncoiler—Feeding—Leveling—Punching--rol... | |

| Rack Beam Roll Forming Machine | The profile drawing of rack beam roll forming machine The thickness of Material: 1.5-2.5mm Working flow of rack beam roll forming machine: uncoil... | |

| U Purlin Roll Forming Machine | The profile drawing for U Purlin Roll Forming Machine The thickness of Material: 2.0-3.0mm Working flow: Uncoiler—Feeding—Leveling—Punching--ro... | |

| Heavy Duty Rack Roll Forming Machine | The profile drawing of Heavy Duty Rack Roll Forming Machine The thickness of Material: 1.5-2.5mm Working flow for Heavy Duty Rack Roll Forming Mac... | |

| Z Purlin Roll Forming Machine | The profile drawing of Z Purlin Roll Forming Machine Working flow: Uncoiler—Feeding—Leveling--roll forming---Punching ---hydraulic cut to length—... | |

| Steel Beam Box Roll Forming Machine | The profile drawing of Steel Beam Box Roll Forming Machine The thickness of Material: 1.5-2.5mm Working flow: uncoiler—Leveling—Punching--roll fo... | |

| C Purlin Roll Forming Machine | The profile drawing of C Purlin Roll Forming Machine The thickness of Material: 2.0-3.0mm Working flow: Uncoiler—Feeding—Leveling—Punching--rol... | |

| Cable Tray Cover Roll Forming Machine | Equipment structure for the cable tray cover roll forming machine: Equipment structure decoiler---Leveler---Servo-feeder---Punching----outTable---... | |

| Fully Automatic Cable Tray Roll Forming Machine | Equipment structure of the fully automatic cable tray roll forming machine:Equipment structure decoiler---Leveler---Servo-feeder---Punching----outT... | |

| High Speed Cable Ladder Roll Forming Machine | Equipment structure of the High Speed Cable Ladder Roll Forming Machine: Equipment structure decoiler---Leveler---Servo-feeder---Punching----outTa... | |

| Steel Frame Roll Forming Machine | Main specification of Floor Steel Frame Roll Forming Machine: A. Manual uncoiler 1) Capacity: 5ton 2) Feeding width: MAX 1300mm 3)... | |

| Channel Cable Tray Roll Forming Machine | Equipment structure of the Channel Cable Tray Roll Forming Machine: Equipment structure of the Channel Cable Tray Roll Forming Machine decoiler... | |

| Barrier Roll Forming Machine For Highway | The profile drawing for Barrier Roll Forming Machine for Highway The thickness of Material: 3.0-4.0mm Working flow: Hydraulic uncoiler—Feeding—Lev... | |

| Roll Formers | Main specification for Roll Formers: A. Manual uncoiler 1) Capacity: 5ton 2) Feeding width: MAX 1300mm 3) Expanding range: 480-520... | |

| Highway Guardrail Forming Machine | The profile drawing of the Highway Guardrail Forming Machine The thickness of Material: 3.0-4.0mm Working flow: Hydraulic uncoiler—Feeding—Leveli... | |

| Metal Deck Roll Forming Machine | Main specification: A. Manual uncoiler 1) Capacity: 5ton 2) Feeding width: MAX 1300mm 3) Expanding range: 480-520mm B. Main rol... | |

| Floor Deck Roll Forming Machine | Main specification of Floor Deck Roll Forming Machine: < A. Manual uncoiler 1) Capacity: 5ton 2) Feeding width: MAX 1300mm 3) Expan... | |

| Roof Tile Roll Forming Machines | The profile drawing for reference The thickness of Material: 0.3-0.8mm Working flow: Decoiler—Feeding—Roll forming----Hydraulic stepping--hydraulic... | |

| Galvanized Tile Roll Forming Machine | The profile drawing for reference The thickness of Material: 0.3-0.8mm Working flow: Decoiler—Feeding—Roll forming----Hydraulic stepping--hydra... | |

| Steel Roof Tile Roll Forming Machine | The profile drawing for reference The thickness of Material: 0.3-0.8mm Working flow: Decoiler—Feeding—Roll forming----Hydraulic stepping--hydrauli... |