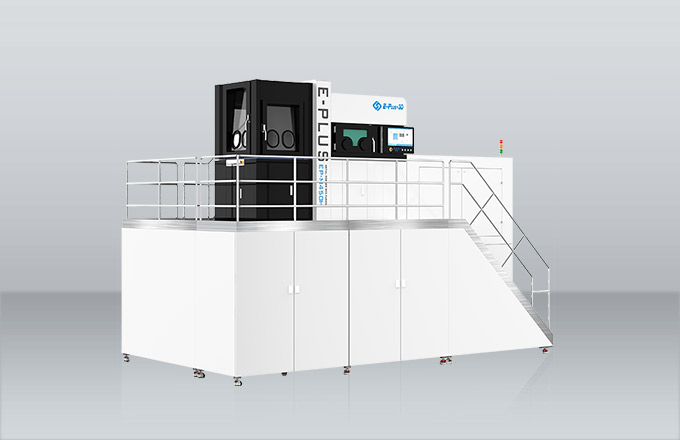

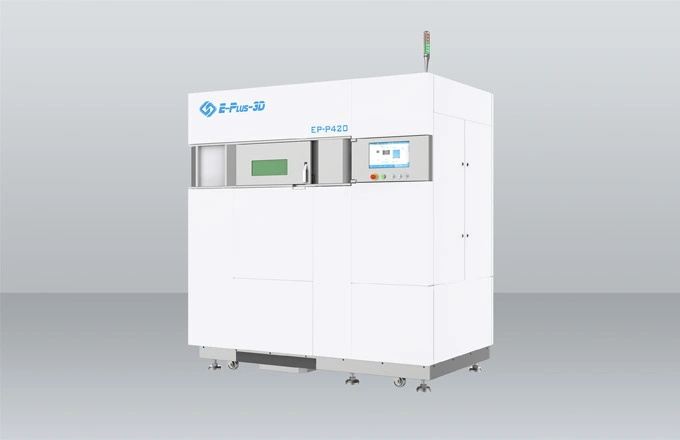

Eplus3D EP-M650 Metal 3D Metal Printing Machine

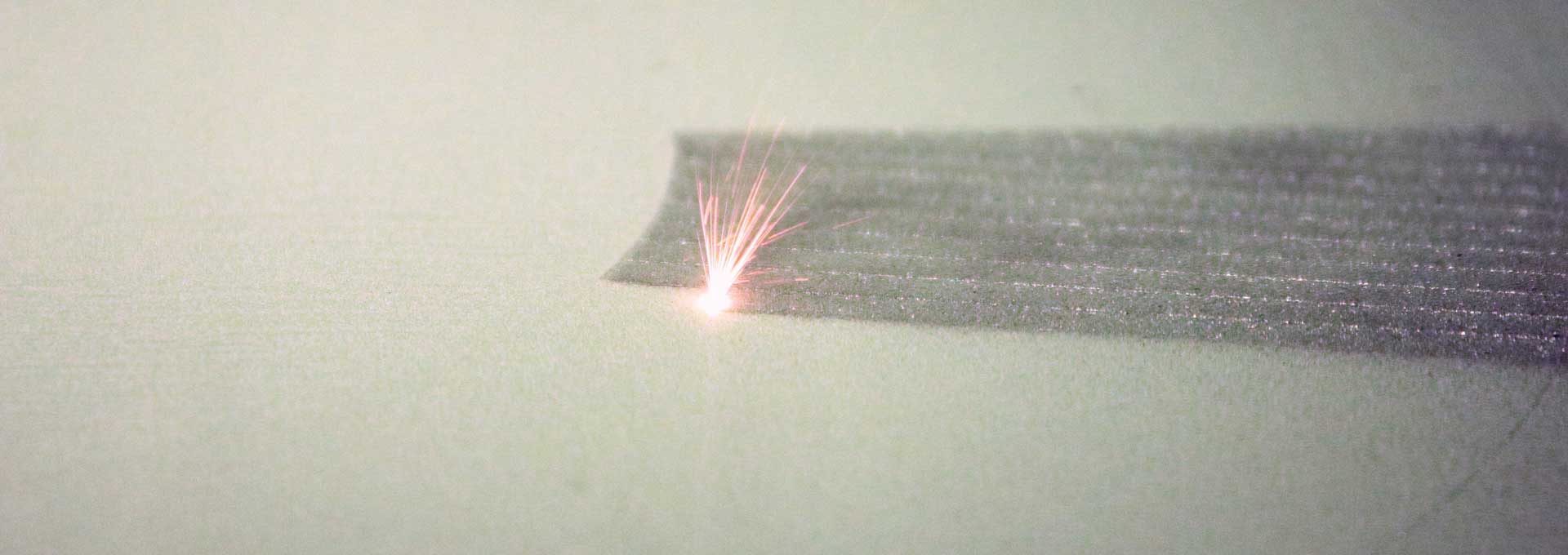

Using MPBF™ (Metal Powder Bed Fusion) technology, EP-M650 is using a large building envelope and 4/6/8 laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase.

The system can operate with various metal powders such as titanium, aluminum and nickel alloy, maraging steel, stainless steel, cobalt chrome and other materials. It is suitable for the direct manufacturing of large-size, high precision and high-per- formance parts in the aerospace, aviation and automotive industry,etc.

EP-M650 Large Format Metal 3DPrinterFeatures

EP-M650 Metal 3d Printer Feature High Effciency Productivity

High Effciency & Productivity

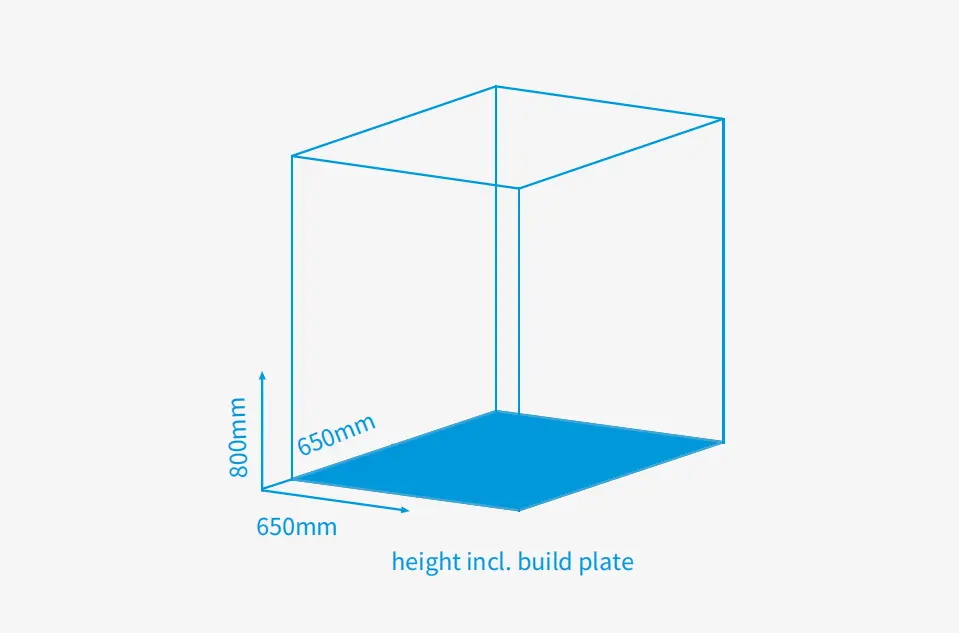

Printing of mass-individualized parts in the 340 Liter (650 x 650 x 800 mm) build chamber.

Four lasers are printing simultaneously with up to 190 cm³, which increased efficiency by 3.5 times compared to a single laser system.

Printing large layer thicknesses of more than 60 um is possible.

Stable Quality, Good Consistency

High parts accuracy in the overlap area of 0.1 mm. The deviation of mechanical properties compared to a single laser system is lower than 3%.

Optimized design the air flow ensures the effective removal of dust and splatter as well as a unifrom parts quality in the whole print bed.

The strict calibration ensures the consistency between parts and batches.

EP-M650 Metal Industrial 3DPrinterFeature Humanized Design High Automation Degree

Humanized Design, High Automation Degree

Friendly user interface with fully automatic one-click printing function.

The build job information is displayed in real time with traceable printing parameters and a detailed printing report.

The one-piece take out function ensures a high automation and low downtime, due to an automatic movement of the building cylinder into the cleaning module after the print is finished.

EP-M650 Metal 3d Printer Feature Real Time Monitoring High Security

Real Time Monitoring, High Security

Safety design, prevent misoperation, electric shock, fire, waste and pollution.

Outstanding overall sealing performance, use and recovery of powder in a closed state.

Environment and gas source state Real-Time Monitoring, safe and reliable.

EP-M650 Metal 3d Printer Feature Perfect After Sales Service

Perfect After-sales Service

We support our customers with technical consulting services, including data evaluation, and application development.

Assisting our customers in new material parameter development. Existing parameter packages are provided free of charge.

Free equipment installation and maintenance during the warranty period, full set of technical training is provided.

What can Eplus3D EP-M650 3D metal printing machine print?

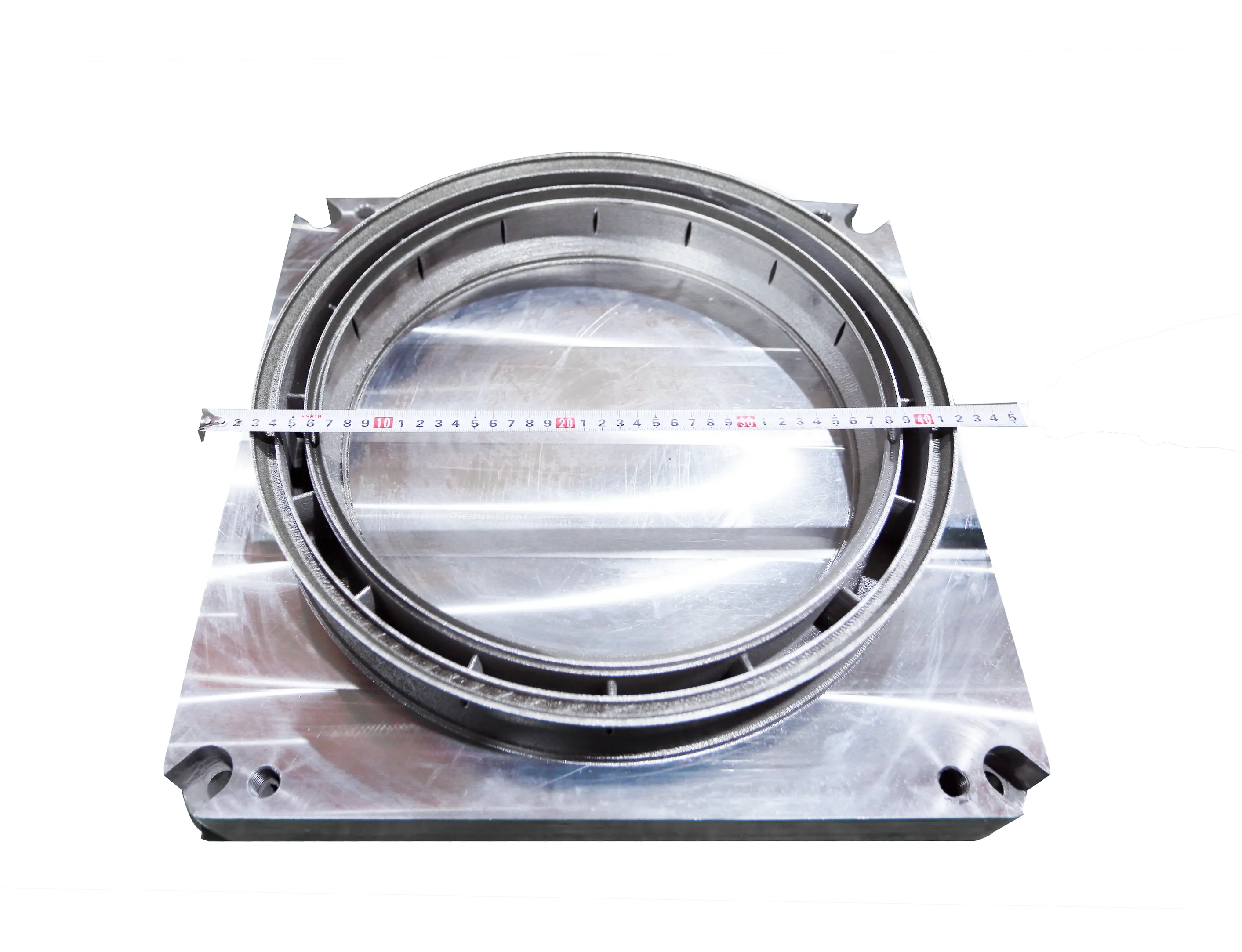

Turbine

Machine: EP-M650(Quad Laser)

Process: Metal Powder Bed Fusion (MPBF)

Material: lN718

Size: 620x150mm

Printing time: 240 h

Application: Aerospace

Frame

Machine: EP-M650 (Quad Laser)

Process: Metal Powder Bed Fusion (MPBF)

Material: Aluminium alloy

Size: Φ470x400x499mm

Printing time:176 h

Application: Aerospace

Turbine

Eplus3D EP-M650 3D metal printing machine Technical Specifications

|

Machine Model |

EP-M650 |

|

Build Volume (X x Y x Z)(height incl. build plate) |

650x650x800mm(25.59x25.59x31.49in) |

|

Optical System |

Fiber Laser 4/6/8 x 500 W (700 W and 1000 W are optional) |

|

Spot Size |

70-120µm |

|

Max Scan Speed |

9 m/s |

|

Layer Thickness |

20 - 120µm |

|

Theoretical Printspeed |

Up to 190 cm3/h |

|

Material |

Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

|

Substrate Heating |

Substrate Heating Temperature 200 °C |

|

Power Supply |

380 V, 50 / 60 Hz, 18 ~ 23 kW |

|

Gas Supply |

Ar/N₂ |

|

Oxygen Content |

≤100 ppm |

|

Dimension (W x D x H) |

6800 x 3945 x 3785 mm |

|

Weight |

15000 kg |

|

Software |

EPControl, EPHatch |

|

Input Data Format |

STL or other Convertible File |

Eplus3D Printer Metal for Additive Metal Printing

Eplus3D printers are designed to work seamlessly with an extensive range of metal powders, including Titanium, Aluminum, Nickel-based alloys, Die Steel, Stainless Steel, and Chrome Cobalt Alloys, cobalt chrome powder, as well as other commonly used materials in metal additive printing. Titanium, known for its exceptional strength-to-weight ratio and biocompatibility, is often utilized in aerospace, medical, and high-performance engineering applications. 3d printing aluminum alloys, prized for its lightweight nature and corrosion resistance, finds widespread use in aerospace, automotive, and consumer goods industries. Nickel-based alloys, including Inconel and Hastelloy, are valued for their high-temperature and corrosion resistance, making them ideal for aerospace, chemical processing, and marine applications. Furthermore, Die Steel, Stainless Steel, and Chrome Cobalt Alloys offer exceptional mechanical properties and wear resistance, catering to a diverse range of industrial requirements. Eplus3D printers' capability to process these varied metal powders ensures versatility and adaptability to meet the demanding needs of modern metal additive printing across multiple industries.

在线联系供应商

Other supplier products

| Additive Manufacturing Photosensitive Resin Material | Eplus3D considers materials to be part of its core competency, Eplus3D's experienced material department has independently developed a portfolio of... | |

| Eplus3D Additive Manufacturing Materials | Eplus3D Additive Manufacturing With Cobalt Chrome Cobalt Chrome powderis an ideal material for many industries, including aerospace and automotive... | |

| Eplus3D Additive Manufacturing With PA11 | PA11 powderis an ideal material for many industries, including Injection Molding. The powder has been tested for use on Eplus3D's SLS 3D printer... | |

| EP-M650 Metal 3D Printer | Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 657 x 657 x 800 mm³ build envelope and four laser systems to ensure a ... | |

| Additive Manufacturing With Nickel Alloys | Nickel Alloys are an ideal material for a wide range of applications, for example in gas turbines for both aerospace, energy and oil and gas. Ep... |

Same products

| Eplus3D Additive Manufacturing Materials | 卖方: Eplus3D | Eplus3D Printing Stainless Steel Additive Manufacturing 3D Printing Stainless Steel is an ideal ... | |

| Eplus3D Polymer 3D Printing | 卖方: Eplus3D | Machines and Materials For Your Needs Eplus3D SLS polymer 3D printers are flexible machines for ... | |

| Eplus3D Resin 3D Printing | 卖方: Eplus3D | Machines and Materials For Your Needs Eplus3D sla 3d printing machines are available from entry-... | |

| Eplus3D Additive Manufacturing Materials | 卖方: Eplus3D | Eplus3D Additive Manufacturing With Nickel Alloys Nickel Alloys are an ideal material for a wide... | |

| Eplus3D Metal Additive Manufacturing | 卖方: Eplus3D | Machines & Materials For Your Metal 3D Printing Demands Eplus3D metal printers are a lab fro... |